Сертифицированный SGS металлический шарик G100 6 мм из нержавеющей

- Категория: Bearing Balls >>>

- Поставщик: Changzhou,Feige,Steel,Ball,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-16-2025 | 0.48 $* | 0.64 $* |

| Aug-16-2025 | 0.96 $* | 0.76 $* |

| Jul-16-2025 | 0.77 $* | 0.45 $* |

| Jun-16-2025 | 0.38 $* | 0.96 $* |

| May-16-2025 | 0.17 $* | 0.92 $* |

| Apr-16-2025 | 0.25 $* | 0.29 $* |

| Mar-16-2025 | 0.60 $* | 0.51 $* |

| Feb-16-2025 | 0.15 $* | 0.34 $* |

| Jan-16-2025 | 0.72 $* | 0.27 $* |

Характеристики

SGS Approved 6mm G100 Metal Ball Stainless Steel Ball

Product Details

| Product | SGS Approved 6mm G100 Metal Ball Stainless Steel Ball |

| Material | Stainless Steel 316 |

| Grade | G100-G1000 |

| Surface | Zero defect,clear |

| size | 2.381-12.7mm |

| Sample | Free sample |

| Application | photographic devices, medical instruments, quick couplings, recirculating balls, ink cartridges, jewels,Special bearings, pumps and valves, aerosol and dispenser sprayers. Utilised in the foodstuff, paper, chemical, rubber, military, textile industry |

| characteristic | Austenitic stainless steel balls with higher corrosion resistance than AISI 304 balls. They show good toughness. AISI 316L has a lower carbon content (maximum 0,030%). Balls are provided in the passivated condition. |

| corrosion resistance | Very good corrosion resistance with respect to organic substances, good resistance to several strong acids (acetic, phosphoric, sulphuric acid) and on sea water. They are subjected to pitting and crevice corrosion in presence of hot chloride solutions and to stress corrosion when temperature exceeds 60°C. They do not resist in contact with hydrochloric and hydrofluoric acids, aqua regia, iron and magnesium chlorides. |

| Certification | ISO 9100;2008SGS |

| Packing | boxes,carton,wood pallet |

Material

| AISI 316 & 316L Stainless Steel | |||||||||

| Materials Standard | Chemmical Composition (%) | Hardness (HRC measured on parallel flats) | |||||||

| C | SI | Mn | P | S | Ni | Cr | Mo | ||

| AISI 316L | ≤0.03 | ≤1.00 | ≤2.00 | ≤0.035 | ≤0.03 | 12-15 | 16-18 | 2.0-3.0 | HRC≤26 |

| AISI 316 | ≤0.08 | ≤1.00 | ≤2.00 | ≤0.035 | ≤0.03 | 10-14 | 16-18 | 2.0-3.0 | |

| Size:2.381-12.7mm Precision Grade: G100-G1000 | |||||||||

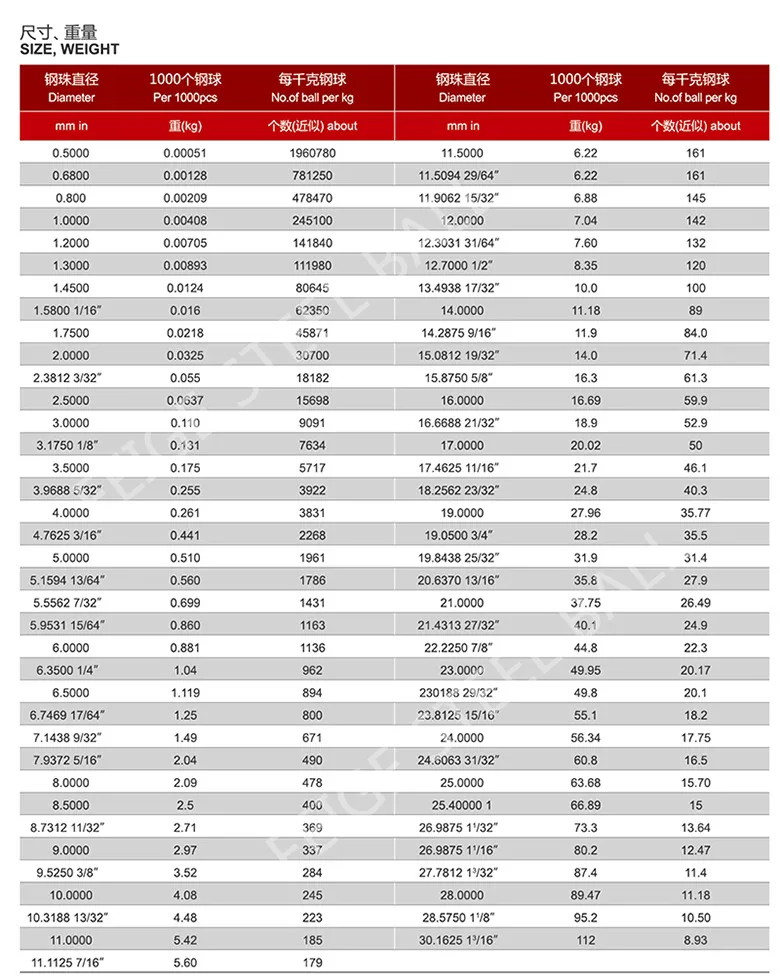

Ball Diameters

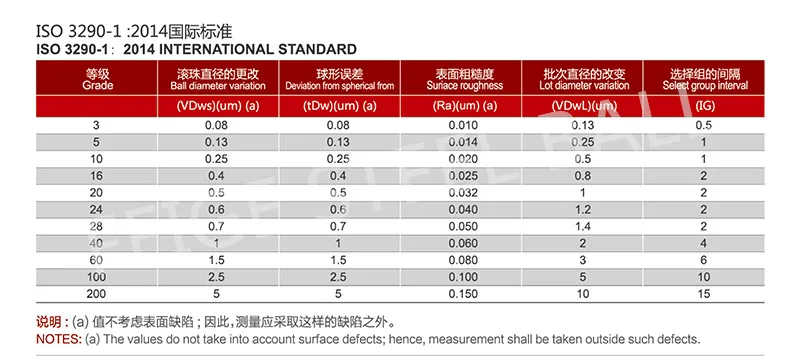

Precision Grade

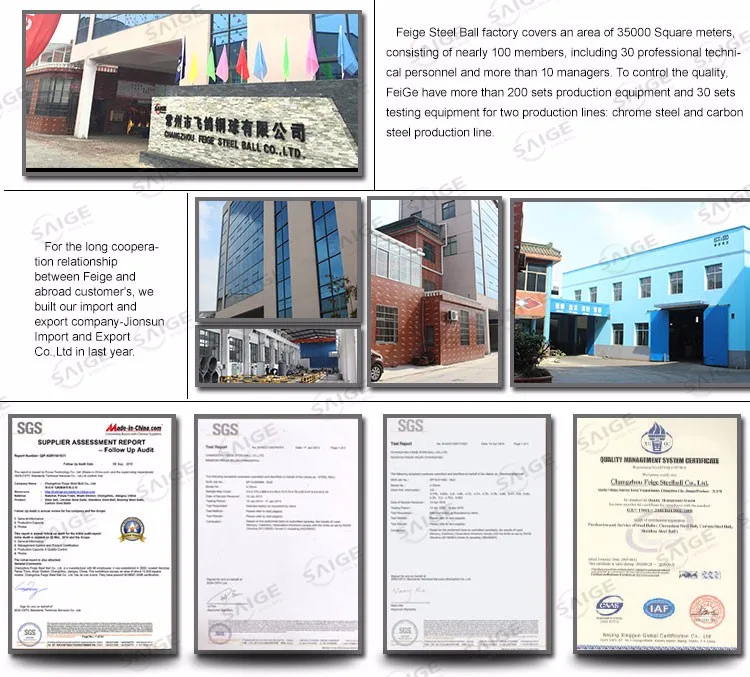

Quality Assurance

Before packing, steel balls are sent for final audit to check for surface roughness, roundness, waviness, lot size variation and hardness in a sophisticated laboratory, according to specified control plans and dock audit procedures. Once all requirements are met, a test certificate is then prepared for the customer. Our sophisticated laboratory is equipped with high precision, worldwide respected machines and equipment and is managed by properly trained and qualified personnel.

Packaging & Shipping

Our Services

Company Information

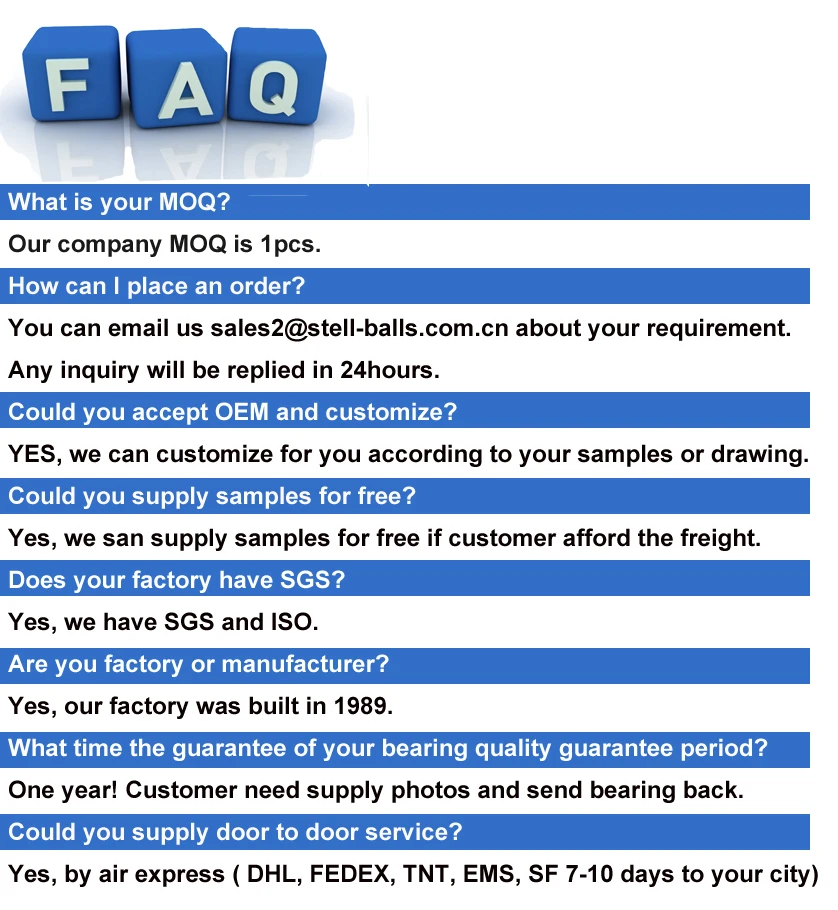

FAQ

Похожие товары

Множество видов высокоточных подшипников из нитрида кремния

US $0.01-$2.00

Хромированный стальной шар 4 мм 6 мм 8 мм G100 G10 AISI52100

US $1.00-$3.00