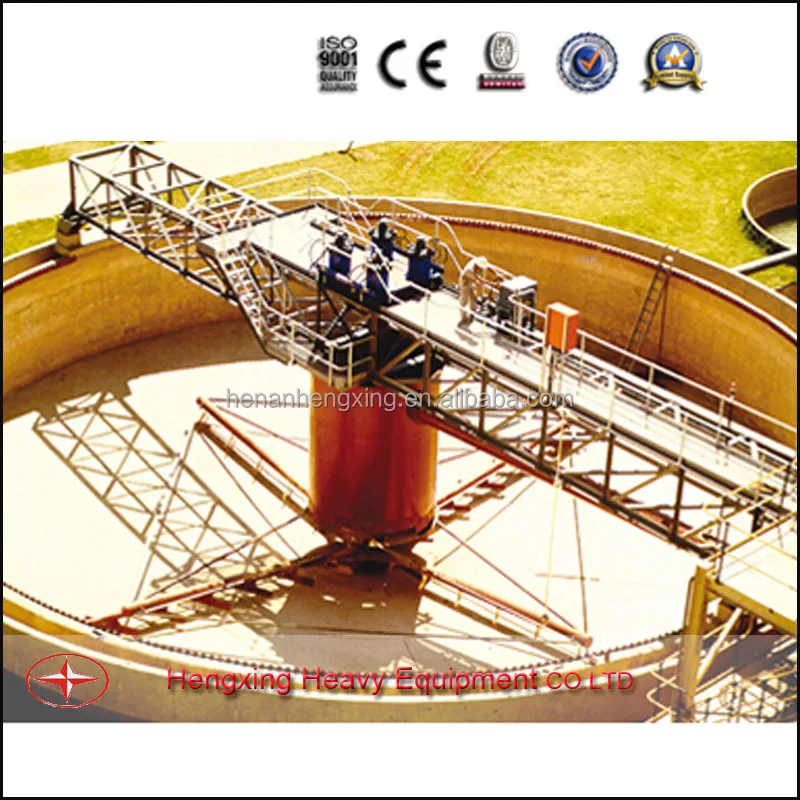

Центровочный горный загуститель для обрабатывающего завода

- Категория: Загуститель для горнодобычи >>>

- Поставщик: Zhengzhou,Hengxing,Heavy,Equipment,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-17-2025 | 7140.7 $* | 7497.47 $* |

| Aug-17-2025 | 7080.8 $* | 7434.32 $* |

| Jul-17-2025 | 5940.25 $* | 6237.57 $* |

| Jun-17-2025 | 6960.77 $* | 7308.33 $* |

| May-17-2025 | 6060.75 $* | 6363.69 $* |

| Apr-17-2025 | 6840.36 $* | 7182.10 $* |

| Mar-17-2025 | 6780.27 $* | 7119.49 $* |

| Feb-17-2025 | 6720.43 $* | 7056.1 $* |

| Jan-17-2025 | 6660.45 $* | 6993.6 $* |

Характеристики

High-Efficiency center drive mining thickener for ore processing is a new type of solid-liquid separation equipment, it has a high concentration of underflow, overflow turbidity small features, are widely used in tailings processing, hydrometallurgy, environmental engineering, mineral processing, environmental engineering and many other fields. It is mainly used for the end of the pulp, metal selection pulp, slurry water, electricity, chemical industry and clarified slurry concentration to achieve the purpose of dehydration.

The ore thickener equipment with a diameter less than 12m is of manual handle type, and

mining thickener for ore processing with a diameter over 12m adopt electric handle devices. Large-scale thickener is usually arranged

with a concrete tank, with overload indicating or alarming devices. This machine has the features like simple

structure, lower wearing and convenient maintenance.

[Power]: 1.1-3KW

[Capacity]:14-250t/h

[Processible Materials]:To dehydrate concentrate and tailings of the ore beneficiation plant.

[Application]:Metallurgy, chemical engineering, coal and non-metal beneficiation.

mining thickener for ore processing is suitable for concentrate and tailings dehydration process in dressing plant, and is widely used for concentrated dehydration processing of slime, waste water and waste residue in metallurgy, mining, coal, chemical industry, building materials, environmental protection and other departments. There are three kinds of thickeners: NZ series centre transmission type thickener, NXZ series center transmission type-- automatic rake high efficient thickener, NZT series peripheral transmission type high efficient thickener.

mining thickener for ore processing working priciple:

The high efficiency mining thickner for ore processing is mainly composed of round concentration basin and rake scraper. The solid particles hanging in the ore pulp of the concentration basin fall under the gravity and the upper part will be clear water, so that the solid particles will be separated from the liquid. The slurry deposited on the bottom of the concentration basin is continuously scrapped by the rake scraper to central discharging port of the bottom of the basin and discharged, and the clear water will overflow along the upper edge of the concentration basin.

Mining thickener for ore processing Technical parameters:

Specification | Concentration pond (m) | Deposit square(m2) | Harrow part | Motor | Processing capacity (t/d) | Total weight(t) | |||||

Model | Specification | Inner diameter | Depth | Pond degree | Method | Height(m) | Rotation time(min/r) | Driving | Lifting | ||

NZS-1 | Φ1.8m | 1.8 | 1.8 | 2.54 | Manual | 0.16 | 2 | Y90L-6 1.1KW | ---- | 5.6 | 1.9 |

NZS-3 | Φ3.6m | 3.6 | 1.8 | 10.2 | Manual | 0.35 | 2.5 | Y90L-6 1.1KW | ---- | 22.4 | 4.3 |

NZS-6 | Φ6m | 6 | 3 | 28.3 | Manual | 0.2 | 3.7 | Y90S-4 1.1KW | ---- | 62 | 10.7 |

NZSF-6 | Φ6m | 6 | 3 | 28.3 | Manual | ---- | 3.7 | Y90S-4 1.1KW | ---- | 62 | 5.1 |

NZ-9 | Φ9m | 9 | 3 | 63.6 | Auto | 0.25 | 4.34 | Y132S-6 3KW | XWD0.8-3 0.8KW | 140 | 8.5 |

NZS-9 | Φ9m | 9 | 3 | 63.6 | Manual | 0.25 | 4.34 | Y132S-6 3KW | ---- | 140 | 7.5 |

NZS-12 | Φ12m | 12 | 3.5 | 113 | Manual | 0.25 | 5.28 | JTC752A-44 5.2KW | ---- | 250 | 11.1 |

NZ-15 | Φ15m | 15 | 4.4 | 176 | Auto | 0.4 | 10.4 | JTC752A-44 5.2KW | Y112M-6 2.2KW | 350 | 26.0 |

NZ-20 | Φ20m | 20 | 4.4 | 314 | Auto | 0.4 | 10.4 | Y100L1-4 5.2KW | Y112M-6 2.2KW | 960 | 28.9 |

NZ-30 | Φ30m | 30 | 7.165 | 707 | ---- | 0.61 | 13.7 | JTC672A-44 5.2KW | YCJ132-S 1.5KW | ---- | 36.6 |

NZS-45 | Φ45m | 45 | 4.633 | 1590 | Manual | ---- | 20 | JTC672A-44 5.2KW | YCJ160-S 2.2KW | 515 | 54.4 |

Pre-sale services:

We will provide you with the prior plan, process flow design and production equipment in line with your special needs.

Sale services:

We will send technicians to you for guiding the equipment installation and commissioning and staff training.

After-sale services: faithfulness

We will regularly pay return visit to customers for establishing a long-term and friendly relationship.

Zhengzhou HengxingHeavy Equipment Co.,Ltd is a professional manufacturer of mining, crushing, screening and drying equipments, with a long-term supply of ore dressing and gravel aggregate industries with crushers, vibrating screens, washing equipments and belt conveyors, drying equipment,rotary kiln,AAC equipement ,etc. we persist in providing highly customized solutions according to different requirements, including single machines, and complete production lines. While expanding domestic market percentage constantly, our products are being exported to Europe, Africa, Central Asia, Southeast Asia, South America, North America, Australia and so on, more than 20 countries and regions totally.

How do you do QA for the thickener?

A:We have special team do strict QA,this is our strengths:

(1)Every gear box will be tested for 8 hours with oil inside to guarantee there is no leak.

(2)Every shaft will be inspected for the centering jumpiness.

(3)Every roller will be checked to make sure its in the range of tolerance critical parts will be inspected for all dimensions.

1.How is the quality of your product?

Our products are manufactured strictly according to national and international standard, and we take a test on every grinder before delivery.

2.Guaranteed:

If product quality is not consistent with the description as we described or the promise before you place order, we promise 100% refund.

3.How about Price?

We are manufacturer of 20 years experiences, and be able to give you the lowest price than market one, and we have a policy that “ for saving time and absolutely honest business attitude,we quote as low as possible for any customer, and discount can be given according to quantity”.

Sara