Динамическая система контроля температуры с водяным охлаждением

- Категория: Mould Temperature Controller >>>

- Поставщик: Wuxi,Guanya,Refrigeration,Technology,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-18-2025 | 0.15 $* | 0.69 $* |

| Aug-18-2025 | 0.10 $* | 0.78 $* |

| Jul-18-2025 | 0.63 $* | 0.12 $* |

| Jun-18-2025 | 0.78 $* | 0.73 $* |

| May-18-2025 | 0.44 $* | 0.58 $* |

| Apr-18-2025 | 0.90 $* | 0.62 $* |

| Mar-18-2025 | 0.29 $* | 0.59 $* |

| Feb-18-2025 | 0.55 $* | 0.55 $* |

| Jan-18-2025 | 0.88 $* | 0.77 $* |

Характеристики

Dynamic Temperature Control System Water Cooled Chiller SUNDI-6A130W

We support customization services, pls consult us for details.

| Temp. range | Heating power | Cooling capacity | Flow pressure(2.5bar) | water cooling(1.5~4bar) | weight | power 380V 50HZ |

| -10~200ºC | 2.5~15kw | 2.5~15kw | 20L/min 2bar~75L/min | 600~2000L | 115~300kg | 3.6~20kw |

| -25~200ºC | 2.5~200kw | 2.5~200kw | 20L/min 2bar~600L/min | 600~2200L 6~36m³/h | 115~2150kg | 4~260kw |

| -25~300ºC | 2.5~200kw | 2.5~200kw | 20L/min 2bar~600L/min | 600~2200L 6~36m³/h | 130~2250kg | 4~260kw |

| -45~250ºC | 2.5~200kw | 2.5~200kw | 20L/min 2bar~600L/min | 600~3200L 7~42m³/h | 130~2250kg | 4.5~280kw |

| -45~300ºC | 5.5~25kw | 5.5~25kw | 50L/min 2bar~150L/min | 1500~3200L 7m³/h | 245~420kg | 9.5~38kw |

| -60~250ºC | 2.5~200kw | 2.5~200kw | 20L/min 2bar~600L/min | 900~4000L 8.5~47m³/h | 205~3280kg | 5~315kw |

| -60~300ºC | 5.5~25kw | 5.5~25kw | 50L/min 2bar~150L/min | 1800~4000L 8.5m³/h | 265~980kg | 10~40kw |

| -70~250ºC | 2.5~15kw | 2.5~15kw | 20L/min 2bar~110L/min | 900~4500L | 190~420kg | 5.2~28kw |

| -80~250ºC | 2.5~80kw | 2.5~80kw | 20L/min 2bar~400L/min | 900~4500L 8~30m³/h | 240~2850kg | 6.5~150kw |

| -90~250ºC | 2.5~80kw | 2.5~80kw | 20L/min 2bar~400L/min | 1100~4000L 8~40m³/h | 260~3150kg | 8~170kw |

| -100~135ºC | 3.5~80kw | 3.5~80kw | 35L/min 2bar~400L/min | 2400~5000L 12~50m³/h | 435~3350kg | 12~200kw |

Main product accessories:

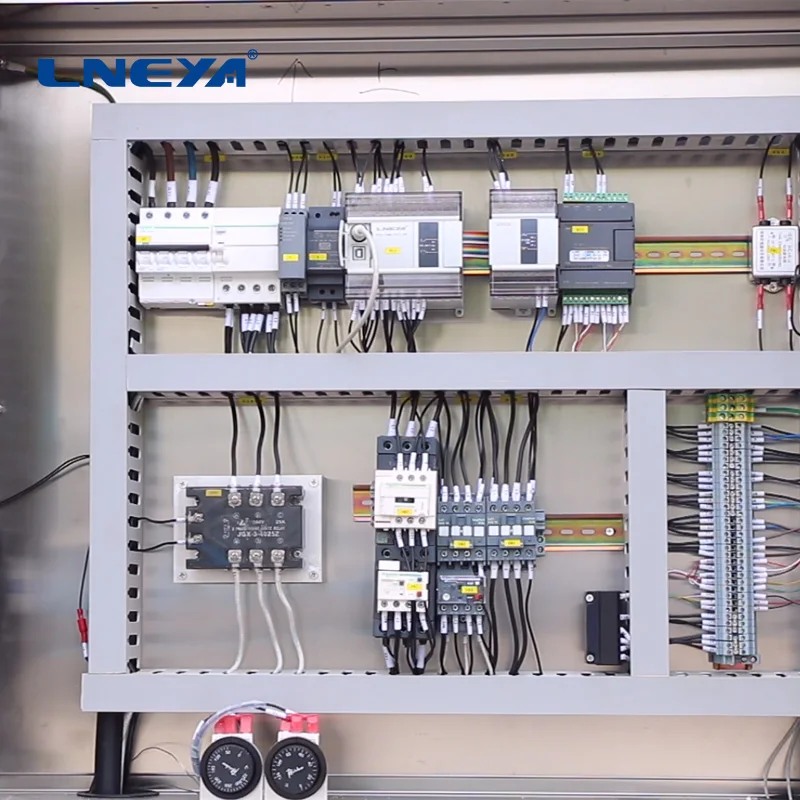

| Control Mode | Feedback PID + Our special dynamic control calculation, PLC controller | ||||||||||||

| Temp. control | Process temp. control and jacket temp. control model | ||||||||||||

| Temp. difference | Set or control the temperature difference between jacket oil and raw material process | ||||||||||||

| Program Editor | 10 programs, each program can edit 42 steps. | ||||||||||||

| Communication Portocol | MODBUS RTU Protocol, RS485 interface | ||||||||||||

| Material temp. feedback | PT100 OR 4~20mA or communication(normal: PT100) | ||||||||||||

| Temp. feedback | The temp. of three points: the inlet and outlet of equipment, reactor material temp.(external temp. sensor) | ||||||||||||

| Pump | LNEYA magnetic drive pump | ||||||||||||

| Compressor | Mitsubishi/Emerson/Carlyle | ||||||||||||

| Expansion valve | Emerson thermal expansion valve/danfoss thermal expansion valve. | ||||||||||||

| Evaporator | DANFOSS/KAORI Plate heat exchanger | ||||||||||||

| Operation Panel | 7-inch touch screen,show temp curve\\EXCEL data output | ||||||||||||

| Safety protection | Self-diagnosis function; freezer overload protection; high pressure switch, overload relay, thermal protection device, liquid low level protection, high temperature protection and temperature fault protection. | ||||||||||||

| Closed circulation system | The whole system is full closed circulation, there is no oil mist at high temperature and no water vapor at low temperature, pressure do not rise up when system is running. The system will supply oil automatically at low temperature. | ||||||||||||

| Refrigerant | R404A/R507C, optional: R448A | ||||||||||||

Application

Package & delivery

As an enterprise certified by ISO9001, LNEYA has reached international standards in the integration of various management systems.

The products of LNEYA, CE is used as a permit for the product to enter the European market.

So far, LNEYA has 11 patents of utility model authorized certificate.

LNEYA has established long-term and stable cooperation with customers at home and abroad.

Many customers are enjoying our high quality after-sales service, sending us all kinds of thank-you letters and expressing our desire to continue to establish long-term and solid cooperative relations.

LNEYA attends various exhibitions at home and abroad every year. At the exhibition, we show the latest research equipment of LNEYA. Every year, long-term cooperative customers will come to exhibitions and communicate with us. We are also actively developing new customers to provide them with high quality machines and services.

After sale service

Quality assurance

Guarantee that the goods are sold to be conform to the provisions of the contract and qualified new products by factory inspection, quality performance, technical indicators and configured are in accordance with manufactures and technical documents stipulated in the contract.

Installation and debugging

After the arrival of the goods, my company or my company agent is responsible for installation and debugging of equipment need on-site installation and debugging.

Inspection and acceptance

After installation and debugging, acceptance by the customer to confirm the goods to be conform to the provisions of the contract and qualified new products, quality performance, technical indicators and configured are in accordance with manufactures and technical documents stipulated in the contract, and after the confirmation of a full set of technical documents, sign the installation acceptance report and confirm acceptance.

Training

At the same time of installation and debugging of equipment, my company’s after-sales service engineer is responsible for technical training for user until user can be skilled of operation. In the process of using equipment by customer, customer can consult relevant technical issues to after-sales service personal of our company at any time, according to the situation, my company will arrange training on site or remote.

After sale service commitment

A full free one year warranty since the date of acceptance, during the warranty period, all repairs and spare parts are free of charge(instrukent malfunction caused bu human factors will be charged of cost price of spare parts); After the warranty period, we will be responsible for maintenance of equipment for lifetime, according to the actual maintenance fees, appropriate fee will be charged.

(PS:There will have extra charge if the customer need on-site service. And customers need to describe the issue first and then send some failed pics or videos in advance, then Lneya judge if it is possible to go for after-Sales on site. )