GX-Y1208 автоматическая печь для закалки оконных

- Категория: Оборудование для обработки стекла >>>

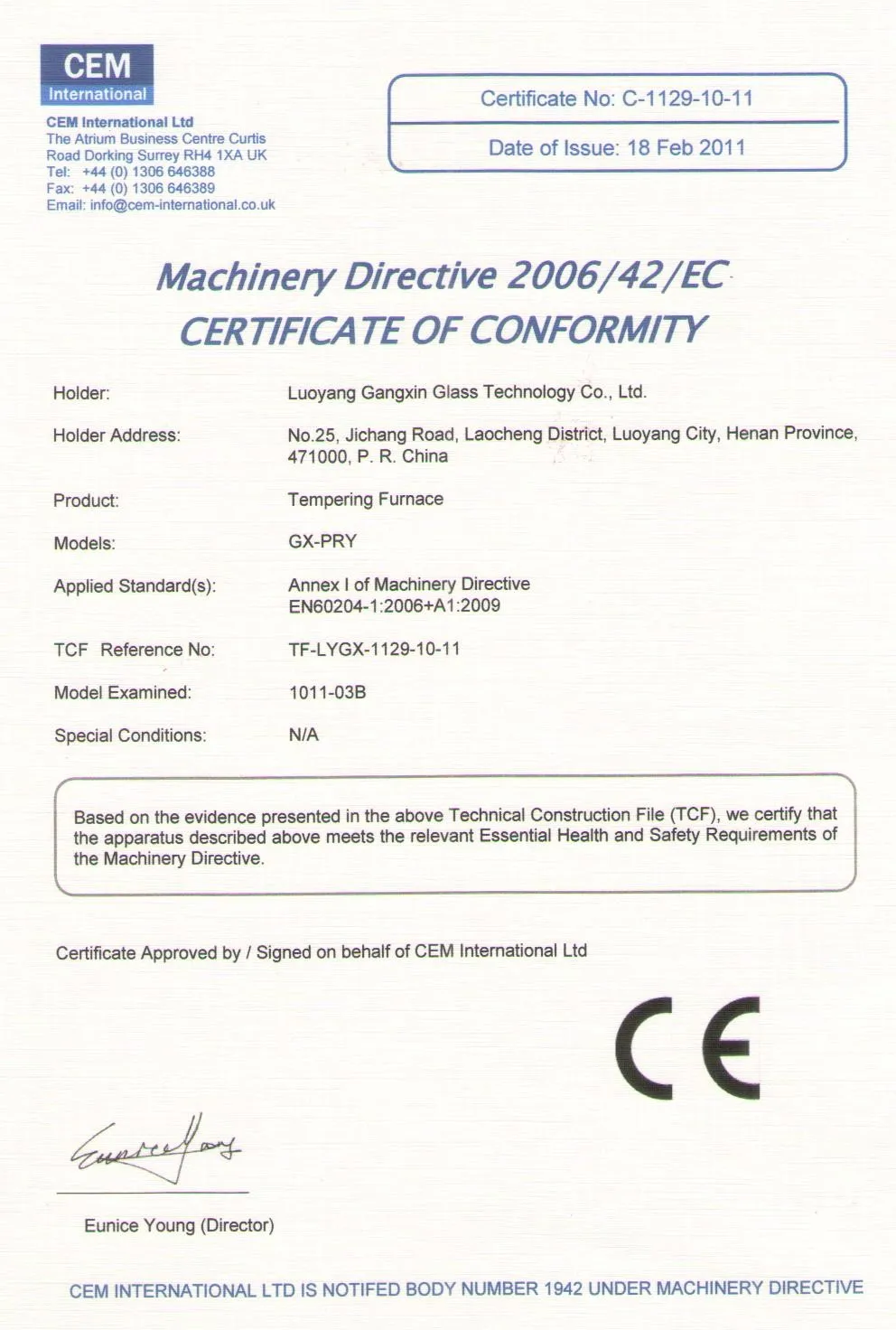

- Поставщик: Luoyang,Gangxin,Glass,Technology,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-20-2025 | 0.41 $* | 0.44 $* |

| Aug-20-2025 | 0.12 $* | 0.27 $* |

| Jul-20-2025 | 0.67 $* | 0.36 $* |

| Jun-20-2025 | 0.46 $* | 0.0 $* |

| May-20-2025 | 0.74 $* | 0.72 $* |

| Apr-20-2025 | 0.23 $* | 0.25 $* |

| Mar-20-2025 | 0.37 $* | 0.88 $* |

| Feb-20-2025 | 0.58 $* | 0.19 $* |

| Jan-20-2025 | 0.40 $* | 0.56 $* |

Характеристики

GangXin Glass Processing Machinery/ Bend Glass Tempering Furnace

Product Application

GX-Y Series Bending Glass Tempering Furnace is mainly used for sidelites for vehicle and ships,shower booth,curtain walls for buiIdings,domestic appIiance,furniture,etc.

Model | Max size(mm) | Min size(mm) | Min Processing Radius | Thickness | Capacity (Batch/h) | Installed Power(kw) |

GX-Y1005 | 100*500(Bend) | 100*280(Bend) | 300 | (3.2)4-6 | 45 | 350 |

GX-Y1208 | 1250*800(Bend) | 200*350(Bend) | 450 | (3.2)4-8 | 28 | 420 |

GX-Y1210 | 1250*1000(Bend) | 200*380(Bend) | 500 | (3.2)4-8 | 28 | 420 |

GX-Y1508 | 1500*800(Bend) | 200*350(Bend) | 450 | (3.5)4-8 | 28 | 480 |

GX-Y1510 | 1500*1000(Bend) | 200*350(Bend) | 500 | (3.5)4-8 | 28 | 480 |

GX-Y1708 | 1700*800(Bend) | 200*350(Bend) | 450 | 4-12 | 28 | 500 |

GX-Y1710 | 1700*1000(Bend) | 200*350(Bend) | 500 | 4-12 | 28 | 500 |

GX-Y1712 | 1700*1200(Bend) | 200*350(Bend) | 550 | 4-12 | 28 | 670 |

GX-Y1715 | 1700*1500(Bend) | 200*400(Bend) | 800 | 4-12 | 28 | 670 |

GX-Y2008 | 2000*800(Bend) | 380*380(Bend) | 450/1000 | 4-12 | 28 | 580 |

GX-Y2010 | 2000*1000(Bend) | 380*380(Bend) | 500/1000 | 4-12 | 28 | 450 |

GX-Y2012 | 2000*1200(Bend) | 380*380(Bend) | 550/1000 | 4-12 | 28 | 600 |

GX-Y2015 | 2000*1500(Bend) | 400*400(Bend) | 800/2000 | 4-12 | 28 | 750 |

GX-Y2415 | 2440*1500(Bend) | 400*400(Bend) | 800/2000 | 4-19 | 28 | 750 |

GX-Y2420 | 2440*2000(Bend) | 400*450(Bend) | 900/2000 | 4-19 | 14 | 500 |

GX-Y2425 | 2440*2500(Bend) | 400*450(Bend) | 1000/2000 | 4-19 | 14 | 650 |

GX-Y2820 | 2850*2000(Bend) | 500*500(Bend) | 900/2000 | 5-19 | 14 | 550 |

GX-Y2825 | 2850*2500(Bend) | 500*500(Bend) | 1000/2000 | 5-19 | 14 | 570 |

GX-Y3020 | 3000*2000(Bend) | 500*500(Bend) | 1000/3500 | 5-19 | 14 | 600 |

GX-Y3025 | 3000*2500(Bend) | 500*500(Bend) | 1250/3500 | 5-19 | 14 | 700 |

GX-Y3030 | 3000*3000(Bend) | 500*500(Bend) | 1500/3500 | 5-19 | 14 | 900 |

GX-Y3525 | 3500*2500(Bend) | 600*600(Bend) | 1500/4000 | 5-19 | 14 | 900 |

Main Features

High Product quality: Opposite roll pressing is adopted for accurate forming which is smooth without spherical surface.

Easy operation: glass curvature is automatically controllerd by computer without any mould, whole process automation is realized for production.

Advanced heating method: Radiation/convection boards in matrix arrangement for heating, intelligent control for spot temperature control.

Convenient parameter storage: large cpacity for storing technical parameters

Very low energy consumption: the energy consumptionof the machine is very low with good thermal insulation and reasonable energy saving.

Board applicability: available for coated glass, patterned glass and all kinds of glass sheet.

Machine Parts

Name: Ceramic roller

Brand: Vesuvius

Original: China

Main Parts

Name: PLC

Brand: Omron

Original: Japan

Machine Parts

Name: Photoelectric switch

Brand: Omron

Original: Japan

Main Parts

Name: Inverter

Brand: Siemens or Schneider

Original: China

Pre-Sales Service

* Guidance for the most suitable tempering line.

* Advice for the customer's workshop

* Arrange visiting the runing machine and our company.

* Other contract details

After-Sales Service

* 7*24 hour online after-sales service

Whatsapp-Michael:+86-18638481875

Whatsapp-Tracy: +86-18637917090

* If not solved online, we will dispatch engineer to repair

* Spare parts will be expressed by DHL or TNT.

GangXin Glass Flat & Bend Glass Tempering Furnace (hard roller)

91.8% Response Rate

GangXin Glass Forced Convection Flat Glass Tempering Furnace

91.8% Response Rate

GangXin Glass Double Curve Glass Tempering Furnace

91.8% Response Rate