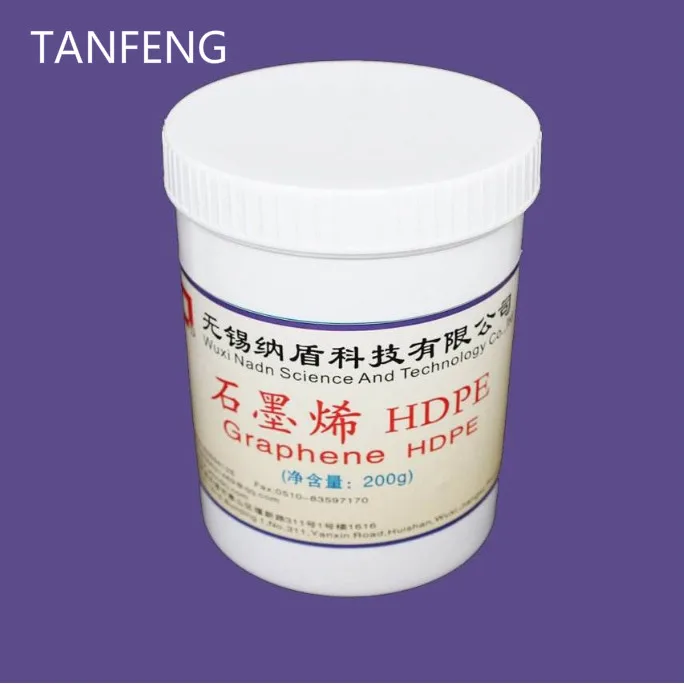

Графеновое нанопокрытие углеродное нанотрубчатое нагревательное охлаждающее

- Категория: Краска для дорожной разметки >>>

- Поставщик: Suzhou,Tanfeng,Graphene,Technology,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-18-2025 | 0.96 $* | 0.79 $* |

| Aug-18-2025 | 0.9 $* | 0.25 $* |

| Jul-18-2025 | 0.84 $* | 0.17 $* |

| Jun-18-2025 | 0.36 $* | 0.67 $* |

| May-18-2025 | 0.42 $* | 0.16 $* |

| Apr-18-2025 | 0.74 $* | 0.92 $* |

| Mar-18-2025 | 0.60 $* | 0.58 $* |

| Feb-18-2025 | 0.96 $* | 0.25 $* |

| Jan-18-2025 | 0.50 $* | 0.41 $* |

Характеристики

Product Name: Hot Sale Nanotechnology Carbon Nanotube Heat Cooling Coating Nano Coating

Description:

1.Product overview

Radiation Heat Cooling Coating is a kind of coating that radiate heat, which could send out the heat from the objects in the form of 1-13.5m

Wave length so that to low the temperature of inside and outside of objects. It can be used in vacuum environment and not subject to surroundings Whats more it has obvious effectiveness in heat cooling. When performing the function of radiation heat cooling, the coating is of the characteristics of self-cleaning property, non-corrosibility, waterproofness, fireproofing, insulativity, acid and alkali stability and constructing convenience etc.

2.Working principle

Radiation heat cooling coating adopts high-performance cooling solution, which is of some special performance such as high visible light, near infrared reflectance, thermal infrared emissivity and stability. Meanwhile It is of good physical and chemical properties as well as application property and various compound performance.

The working principle of this radiation solution is to produce binding force by the condensate of inorganic colloidal particles(less than 100nm). The addition of materials as graphene which of high pyroconductivity and radioactivity increased the coefficient of thermal conductivity. The nonmaterial component that make the coating surface smooth in macro view and rough in micro view could greatly increase the contact area of heat sink with outside, reduce the heat shield, significantly increased the cooling effect.

At the same time, the adding of large quantity of various spinel as Composite infrared radiator, which is transited by electron not only increased the impurity level, improved the coefficient of infrared radiation but also keeping the excellent performance such as corresponding thermal stability, heat resistance, high strength, corrosion resistance and abrasion resistance.

In order to overall improve the strength and stability of cooling coating, we also add Rare Earth Oxide in it to improve the activity of coating composition. REO is the preferred material for doping and stabilizing coating structure.

Main Characteristics |

|

3. Coating parameters

Film color Multi colors

hardness 5H

heat conductivity coefficient >=150w/mk

strength of extension 2500kpa

reflectivity in visible region 85%

anti-corrosion property good

reflectivity near infrared region 80%

adhesive force Grde 1

300 k infrared hemisphere reflectivity 90%

damp heat test 2000 h

applicable temperature -50~600

aging test 2000 h

volume resistivity 1×10^12·m

water resistence 72h

oil resistivity 72H

acid-base resistance property 72h

The Application of Radiation Cooling Coating to LED light

Ps: Tests confirmed that there is a difference of 7 degrees between with radiation cooling coating and without radiation cooling coating.

4. Application:

Radiation heat cooling coatings are with high heat insulation property, and easy to use and meanwhile with protective and decorative function. The object which need to enhance heat dissipation, brush in thin layer, and the object need heat preservation can coat according to actual circumstance to brush a certain thickness.

Coating has high chemical stability and environmental impact is small, and can be used in to the main heat source like solar heat or infrared radiant heat

1, Acidic, alkaline and corrosive environment

2, High and low temperature changing environment

3, High humidity environment

4, High cleanliness requirements of the environment

5, Movement, rotation, vibration environment

6, Limited space or weight of the environment

7, Environment which is in limited inspection and maintenance

8, Alien, irregular and conventional adiabatic constrained environment

5, Target Objects:

Coating with excellent adhesion, easy construction, almost can be used on any clean, dry surface

Coating can besmear to brush in steel, cast iron, zinc, aluminum, copper, stainless steel, magnesium, stone, wood, cement, brick, ceramics, glass, textiles, plastics, paper, organic glass, asbestos, various kinds of fiber board, veneer, asphalt, bubble the foam (sponge), polyurethane, polypropylene coating surface, etc.

In order to guarantee the adhesion effect, if necessary, should make proper preprocessing for the surface

6, Thickness:

According to wavelength penetration , generally is the stronger the penetrating power and the wavelength, the greater the thickness is. If it is used for thermal insulation or is cold, and the thickness of coating on heat resistance (thermal conductivity), should choose according to different purposes.

This product has been able to Swiss environmental certification, CQC China quality environmental protection product certification.

Application:

On the one hand it is used to objects which needed heat cooling, such as CPU, LED lamps and lanterns, electrical appliances, racks, wire and cable, radiator, fan, heat pipe, water tank, transportations etc. On the other hand, it also can be used in the smaller transmission coefficient objects. Coating in plastic, rubber, PVC, cloth, leather, pottery, porcelain, cement, paper, glass, wood to speed up the cooling.

| Suzhou Tanfeng Graphene Technology Co.,Ltd in China ---A professional earliest supplier of graphene,carbon nanotube,fullerene,graphene heating clothes,waist belt,neck belt,kneecap and many other graphene heated products and so on.Has established long term cooperation with Tsinghua University, Fudan University, Chinese Academy of Sciences, University of California at Berkeley and other well-known domestic and foreign research institutes for Research and Development. Graphene physical therapy heated products is our mainly development direction now.Our graphene heated products not only could keep warm but also have the effect of physical therapy.It will bring a new experience to human beings |

Our goal is to provide customized solutions for the market and customers, whether it is a graphene heated product or graphene raw materials, as long as the customer needs, we will do our best to do the best. For any customer advice and feedback, we will give patient and meticulous response and equal treatment.For any customer inquiries, we will give the most professional and most reasonable offer with fastest speed.

We are grateful for the customer's complaint, because this is the driving force for our progress.

We are never satisfied with the status quo, and be tireless on the road of innovation and pursuing professional knowledge.

For any order of the customer, it will be completed on time by mass.

If you have interest in our Far Infrared Graphene Heated Shoulder Pad,please feel free to contact me.

FAQ

[Q]: Are you a manufacturer or a trade company?

A : We are a graphene therapy heated products' factory, and we have our own foreign trade department, we market our own products.

[Q]: What is your MOQ?

A :Usually 1-10 pieces

[Q]: What is your time of making samples?

A :Usually we will spend about 5-25 working days to make samples.

[Q]: What is your delivery time?

A :10-15 working days.

[Q]: What is the shipping port?

A :Shanghai,Ningbo or Shenzhen

[Q]: How can I get your quotation?

A :Please let me know the product details you need,your purchase quantiy and other requirements,etc print.

We will provide the quotation according to your request as soon as possible.

[Q]: What kind of product you can produce?

A :We can produce all kinds graphene heating products.