Металлический Потолок Омега канал обрешетки профилегибочная

- Категория: Обрешечивающие машины и машины для стальной рамы >>>

- Поставщик: Cangzhou,Zhongtuo,International,Trade,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-17-2025 | 0.37 $* | 0.20 $* |

| Aug-17-2025 | 0.4 $* | 0.24 $* |

| Jul-17-2025 | 0.77 $* | 0.34 $* |

| Jun-17-2025 | 0.42 $* | 0.94 $* |

| May-17-2025 | 0.81 $* | 0.58 $* |

| Apr-17-2025 | 0.67 $* | 0.12 $* |

| Mar-17-2025 | 0.13 $* | 0.47 $* |

| Feb-17-2025 | 0.90 $* | 0.63 $* |

| Jan-17-2025 | 0.2 $* | 0.88 $* |

Характеристики

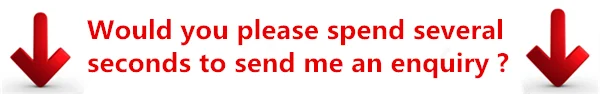

Metal ceilling omega furring channel roll forming machine

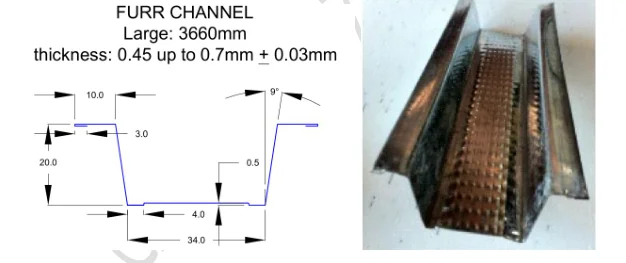

take a random profile drawing for furring channel for example.

working flow for Furring Channel/Omega Channel Roll Forming Machine:

Uncoiling→Feeding material into machine→Roll forming→Measuring length→ Auto cutting→Products receiving

Product name | Furring Channel/Omega Channel Roll Forming Machine | |||

NO. | Items | Parameters | Remark | |

1 | Suitable Material | Type | GI/PPGI/AL |

|

|

| Thickness | 0.40-0.80mm |

|

2 | Product Specifications | Length | Any length |

|

|

| Length Tolerance | ±2mm/6m |

|

3 | Working Speed | 25 m/min | Standard machine | |

4 | Control System | Mitsubishi/Siemens PLC& transducer | Custom | |

5 | Total Power | 7KW |

| |

6 | Total Weight | About 2.5T | Up to final design | |

configuration of Furring Channel/Omega Channel Roll Forming Machine:

No. | Name | Unit | Qty |

1 | Manual decoiler | set | 1 |

2 | Main forming machine | set | 1 |

3 | PLC control system | set | 1 |

4 | Hydraulic pump station | set | 1 |

5 | Post cut | set | 1 |

6 | Electric motor | set | 1 |

7 | Output table | set | 1 |

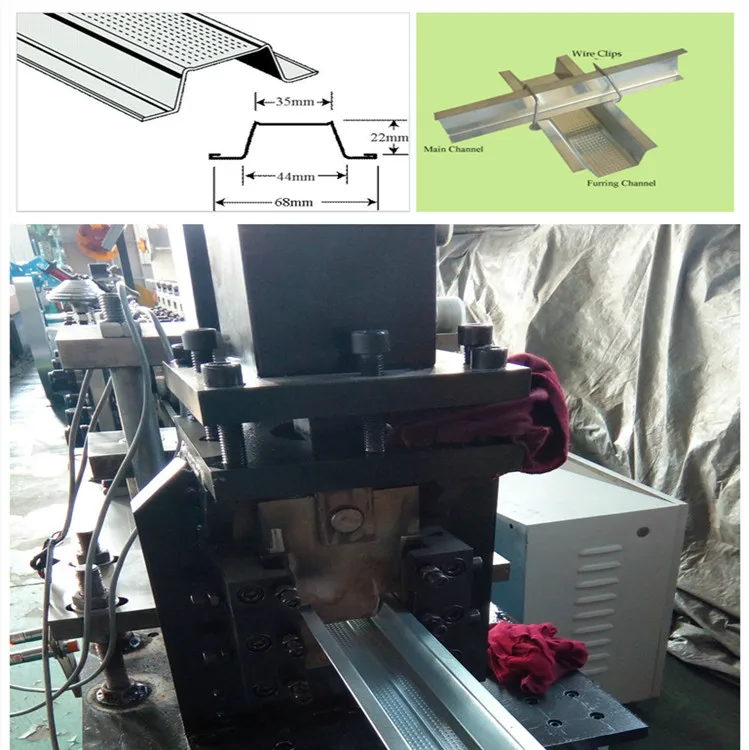

details of Furring Channel/Omega Channel Roll Forming Machine

Un-coiler System

Usage: It is used to support the steel coil and uncoil it in a turntable way.

Passive uncoil pulled by roll forming system

Loading capacity | Uncoiling width | Inner diameter |

1.5T | 300mm | 450-550mm |

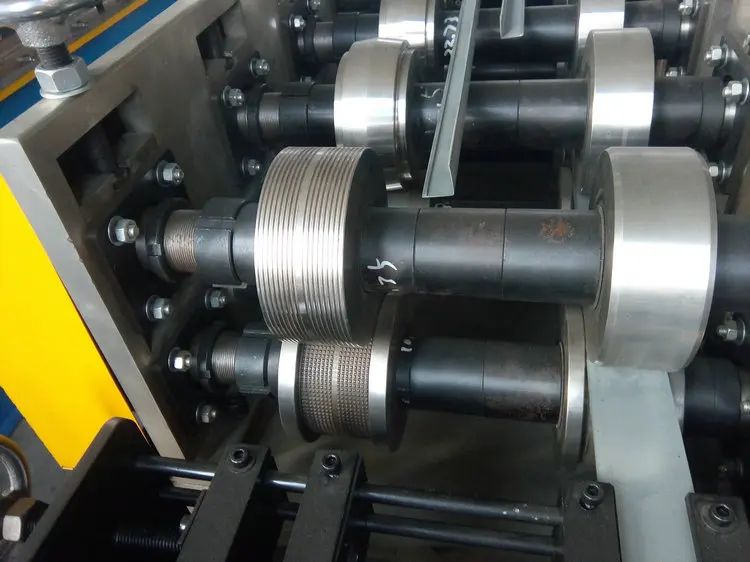

Forming device

Usage: In order to keep the product shape and precision, adopts welded sheet structure, motor reducer drive,gear transmission,roller was chromed which can keep the molding plate surface smooth and not easy to be marked when it is working

Feature : Ensure stability , precision and lifetime.

No. | Main parameter of Furring Channel/Omega Channel Roll Forming Machine | |

1 | Length of the main part | 4800*800*1400 |

2 | Weight of main part | About 2.5 t |

3 | Voltage | 380V/50HZ3Phase (as customer's request) |

4 | Roller fixer | Guide column |

5 | Frame | Middle plate welded Memorial arch frame type |

6 | Frame thickness | 25mm |

7 | Drive mode | Gear |

8 | Material of rollers | GCr12MoV quenching treatment58-60° |

9 | Material of shafts | 45# steel with tempering |

10 | Diameter of shafts | φ40mm |

11 | Number of rollers | 12 rollers |

14 | Main power | 4kw (Cycloidal planetary gear speed reducer) |

15 | embossing and Logo is acceptable | |

Cutting device

Advanced hydraulic drive, automatic punching and cutting after forming, no distorting or wasting, high level safety factor.

Blade Material | Cutting system |

GCr12MoV quenching treatment58-60° | Full automatic |

Controlling device

Screen | PLC | Coder |

Text screen displayer |

Taida DVP14ES from Taiwan |

Omron |

Hydraulic

Orgin | Power |

Advanced hydraulic system from Taiwan | 3kw |

Cangzhou ZHONGTUO Roll Forming Machinery Co., Ltd is a professional manufacturer and exporter of cold Furring Channel Rollforming Machines. All products comply with international quality standards and are greatly appreciated in markets throughout the world, such as Asia, Africa, Europe,South America, Australia and so on.

We specialized in manufacturing metal roofing Furring Channel Rollforming Machine, purlinmachine,Glazed tile roll forming machine, floor tile making machine, rolling shutter machine, metal stud Furring Channel Rollforming Machine,highway guardrail roll forming machine,steel door frame making machines, gutter machine,no beam roof tile machine, pipe welding machine.

FAQ:

1.How to get a quotation of Furring Channel/Omega Channel Roll Forming Machine?

Give me the profile drawing and thickness for the furring channel ,this is the important.

Other spicific requirements is welcome,such as the speed,power and voltage you want.

2. Terms of payment:

30% T/T, Balance to be paid before shipping after inspection.Also we accept the payment L/C, O/A , D/P.

4. What is your after-sale service?

Furring Channel/Omega Channel Roll Forming Machine warranty period is 24 months,if the broken parts can't be repaired,we can send new to replace for free,but you need to pay the express cost yourself.we supply the technical support for the whole life of the equipment.

6. How to visit your company?

a.Fly to Beijing airport: By high speed train From Beijing Nan to Cangzhou Xi (1 hour), then we can pick up you.

b.Fly to Shanghai Airport: By high speed train From Shanghai Hongqiao to Cangzhou Xi(4.5 hours), then we can pick up you.

If you want to know more ,please copy and paste the link into your web browser.

https://www.youtube.com/channel/UCea3FfE-LRSPhycSuiY4snA

https://www.youtube.com/channel/UCea3FfE-LRSPhycSuiY4snA