Промышленная Электромагнитная Индукционная панель нагревателя

- Категория: Industrial Heater >>>

- Поставщик: Zhongshan,Shuangping,Electronic,Technology,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-17-2025 | 0.6 $* | 0.30 $* |

| Aug-17-2025 | 0.91 $* | 0.38 $* |

| Jul-17-2025 | 0.98 $* | 0.21 $* |

| Jun-17-2025 | 0.50 $* | 0.30 $* |

| May-17-2025 | 0.82 $* | 0.45 $* |

| Apr-17-2025 | 0.71 $* | 0.32 $* |

| Mar-17-2025 | 0.88 $* | 0.82 $* |

| Feb-17-2025 | 0.69 $* | 0.46 $* |

| Jan-17-2025 | 0.55 $* | 0.45 $* |

Характеристики

3.5kw power saving induction heating control board

Caution:

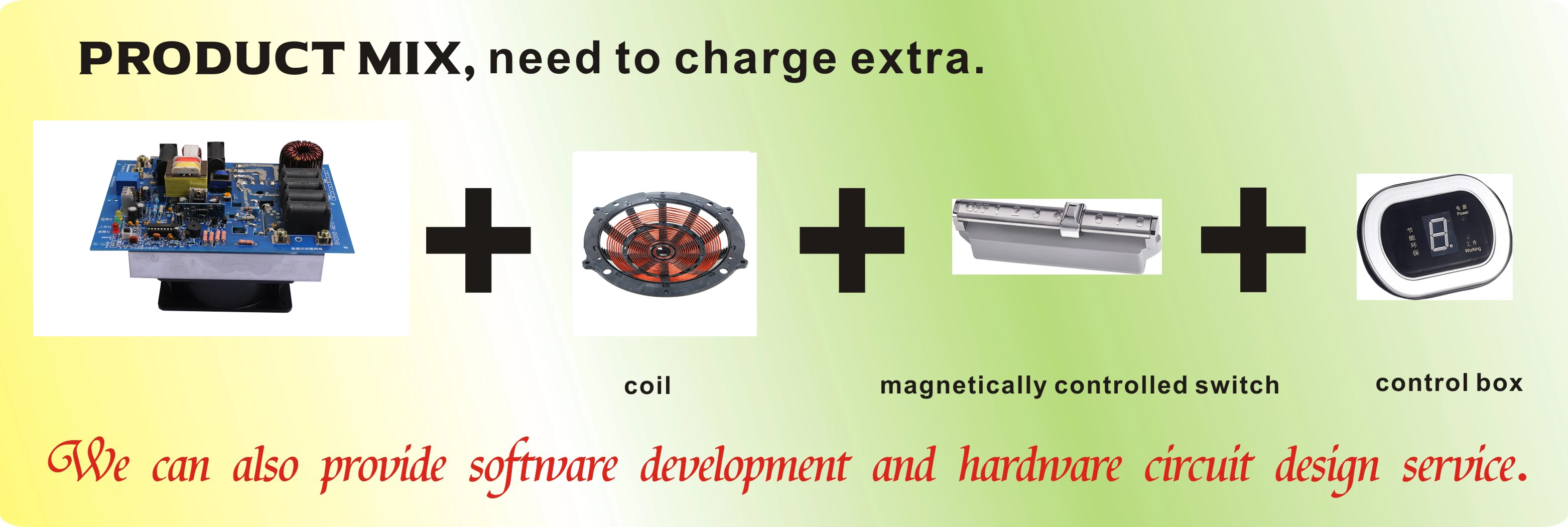

The control board is only a component of induction heater(cooker), you also need some knowledge of induction technology for assembly the system for another components like coil and temperature controller etc. To ensure the product work normal, you should have proper installation technology to install the board correctly as per our operation manual.

| Product model | Working voltage | Power range | Capacity of inductance | Conversion efficiency | Working temperature | Surge protection | Distance from inductin coil to heater |

| BH2088-2KW | 220V | 1600-2000W | 160uH+20 | >90% | -10 ℃ ~ 50 ℃ | 20-23MM | |

| BH2013-MB-2.5KW | 2000-2500W | 120uH+20 | >90% | -10 ℃ ~ 50 ℃ | ±1500V | 17-25MM | |

| BH2098-MB10-3.5KW | 220V | 2500-3500W | 120uH+10 | >90% | -10 ℃ ~ 50 ℃ | ±1500V | 16-22MM |

| BH2013-MB-5KW | 220V | 3000-5000W | 80uH+10 | >90% | -10 ℃ ~ 50 ℃ | ±1500V | 15-20MM |

Induction heating heats the metal cylinder itself while additional thermal insulation material can be wrapped on the barrel to preserve heat at the same time. It greatly reduces heat loss and improves thermal efficiency, achieving significant effect. by saving up to 30% ~ 70% electricity.

As a substitute of traditional electrothermal products, it is widely used in the heating and power saving of plastic and rubber products, chemicalindustry, medicine, food, energy,printing, construction profiles and other industries, such as: plastic wire drawing, film blowing, granulation, injection molding and other heating; Cable production extruder, extrusion machine, thermoplastic plastic pipe, profile production heating; Pipe heating, thermostatic control heating, etc.

The range of induction control board application:

1.Heating industy;

2.Building materials industries, such as: gas pipe production line, plastic pipe production line, PE plastic hard flat net, geonet units, automatic blowing molding machines, PE honeycomb panel production line, single and double wall corrugated pipe extrusion line, compound air cushion film machine, hard PVC pipe, core layer foam pipe line, PP transparent sheet extrusion production line, polystyrene foam extrusion pipe, PE stretch film;

3.Core kit of high-power commercial induction cooker;

4.Energy, food industry, such as: heating of crude oil pipelines; Food machinery, such as: the roasting machine needs electric heating equipment, etc;

5.Medical and chemical industry, such as: special medical infusion bag production line, plastic equipment, chemical industry, liquid heating pipeline and so on;

6.Building materials industries, such as: gas pipe production line, plastic pipe production line, PE plastic hard flat net, geonet units, automatic blowing molding machines, PE honeycomb panel production line, single and double wall corrugated pipe extrusion line, compound air cushion film machine, hard PVC pipe, core layer foam pipe line, PP transparent sheet extrusion production line, polystyrene foam extrusion pipe, PE stretch film.

1.Instructions for 3.5KW motherboard assembly

(1) There are 3 lights respectively indicating power, work and fault. The "Power" and "Work" are on if the machine is functioning properly and the "Fault" is off. If there is a rundown, the "Power" and "Work" are off and the "Fault" is on.

(2) Connect to the 2 posts reading "AC 220V" to get access to power. There is no need to distinguish L or N wire.

(3) Coils are attached to 2 posts reading "two ends of coils". Tighten the screw.

(4) Set "work if power is on" at Factory Setting to start. A black short-circuited line at the socket of the "soft switch" can control short circuit. You can also start the machine by gently removing the short-circuit line, then attach one end of a connecting lead (two-wire cord with a 2-pin plug at each end) to the socket of the soft switch and the other end to the two contacts of therrmostat controller.

2.Notifications of 3.5KW electromagnetic heating control board

(1) Requirement of the shell

The control board should be installed inside the shell since the controller carries high pressure and large current electronics are used. Then it is connected to heating coils, power and thermostat controller by insulation wire. This can prevent electric shock even if electric parts are touched. Also, since the board will generate heat, the shell should be designed to be easy for ventilation and thermal dissipation.

(2) Requirement of the coils

6m2 insulation high temperature resistance wire is required for 3.0-3.5kw control board. Coils are generally circular with capacity of inductance 120±10uH (Measured by Victor's BICTOR6243 inductometer when coil is wound on the cylinder)

Note: circular coils usually wind 28 laps. Laps can vary depending on the diameter of the cylinder.

(3) Winding of heating coil

Wind the coils according to user's specific requirements. Make sure the winding direction should be the same to with the parameter in one single ferric cylinder. Distance between each section of coils should be greater than 50 mm.

(4) Requirement for the distance between heating coils and heated metal.

The distance from the surface of the coils to the surface of the heated metal should be adjusted according to diameter of coils. In the case of 3.5KW control board, the larger diameter of cylinder, the shorter distance is needed. On the contrary, the smaller diameter of cylinder, the further distance is needed. 15-22mm is most suitable because the controller will deteriorate when it is too close, causing heat and even damaging IGBT while power could be gradually degraded when it is too far, causing adjustment failure due to over-voltage protection circuit..

(5)Assembly of 3.5KW Electromagnetic heating control board

The controller can work either by directly turning on power or being controlled by the thermostat controller.

a, Directly connecting to power: Connect the 220V power to the L and N wire of the control board through an insulated wire. Connect the post of lead lines of the coils to the terminal of the controller (Make sure if it is firmly contacted). This board has been set to work once there is power supply.

b, Using thermostat controller: Connect the 220V power supply to the L and N wire of the control board through an insulated wire. Connect the post of lead lines of the coils to the terminal of the controller (Make sure it is firmly contacted). Gently remove the black short-circuit line on the socket, then attach one end a connecting lead (two-wire cord with a 2-pin plug at each end) to the socket of the soft switch and the other end to the two contacts of therrmostat controller. Test the machine. Note: The thermostat is not allowed to contact with the mains or other high-voltage.

c. Combination of control boards: If you need one thermostat to simultaneously control the switches of several boards, first pick a main control board, and then use the connecting line (two-wire cord with a 2-pin plug at each end) to connect the "sub-panel control" of the main board to the "voltage control" of another board. Repeat the above steps if you want to add more boards.

If you have any questions, please click to contact me. Thank you.

Why choose us?

Our company specializes in induction heating for 12 years. We are committed to provide customer high quality products with competitive prices. We can also provide software development and hardware circuit design service. Our product can be comply all the standard of the worldwide and different requirement and all of the customize. Such as CE,GS,CB,FCC, etc.

1. May I take some samples to test before placing the order?

One to two samples of each model can be offered for your testbefore placing the order. But you should pay the sample fee andfreight first.

2. How long can you offer the samples?

1-7 days after receiving the payment.

3. What`s your payment term for sample?

You can pay through RMB account or USD account. For USD account, you can pay by paypal or t/T payment.

4. What is the MOQ of your products?

It depend on models. Some MOQ of our products is 1000 pieces for one model one size, we have stock models, 100 pieces is acceptable.

5. We`d like to print our logo on the appliances. Can you make it?

We provide OEM service which including logo printing, gift box design and carton design if you can give me the license at sign.

6. How about the delivery time?

20-40 days after the receipt of deposit and confirmation on all designs based of normal condition.