Резервуар для перемешивания цианида золота энергосберегающий резервуар

- Категория: Чан для выщелачивания >>>

- Поставщик: Yantai,Jinpeng,Mining,Machinery,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-16-2025 | 1190.63 $* | 1250.88 $* |

| Aug-16-2025 | 1180.43 $* | 1239.22 $* |

| Jul-16-2025 | 990.83 $* | 1040.90 $* |

| Jun-16-2025 | 1160.66 $* | 1218.99 $* |

| May-16-2025 | 1010.1 $* | 1061.85 $* |

| Apr-16-2025 | 1140.70 $* | 1197.91 $* |

| Mar-16-2025 | 1130.31 $* | 1187.78 $* |

| Feb-16-2025 | 1120.92 $* | 1176.71 $* |

| Jan-16-2025 | 1110.0 $* | 1166.53 $* |

Характеристики

Yantai jinpeng Mining Machinery CO., LTD

The excellent one stop service supplier at home and abroad

Professional mineral processing design, equipment production,installation and conmissioning institue.

24-hour free hotline:+86-01056052822 Technology consulting:+86-13381157789

Product Introduction

Compare double impeller leaching stirred tank with the ordinary mixing tank, it adopts the double impeller, the mixing of pulp can be more uniform, in terms of energy consumption, the more saving energy. the impeller use wrapping adhesive technology, long service life, moral give in to the gas use is for gas, air evenly.

Scope of application

the proportion of small, low viscosity, sedimentation velocity is slow, ore particle size in 200 yard accounted for more than 90%, pulp density is less than 45% of gold leaching, adsorption and other mixed in.

structure

![RZZ]D2VVD_0L9J[$(`M]Y`A.jpg](http://g01.s.alicdn.com/kf/HTB1jss3FFXXXXXFaXXXq6xXFXXXj/200453130/HTB1jss3FFXXXXXFaXXXq6xXFXXXj.jpg)

1. Vertical axis 2. Agitator 3. Impeller 4. Drive of motor 5. Beam 6. Railing

Working principle

Pulp in double impeller and stirring under the action of the drag, the flow in the center from top to bottom, the diffusion of damping plate, on the lower end of the shaft into the air, and pulp are mixed and upward circulation, forming uniform suspension mixture.

Advantages

1.The machine features a reasonable and compact structure, and high transmission efficienty;

2.Twin impeller is used ,which has bigger diameter,lower turning speed,lower agitation power consumption,and lower wear of the carbon;

3.Air is sent to the bottom via pipes , so that it is evenly spared with less bubles; It gives moderates agitation strength, to keep the slurry density and fitness to be basically uniform is the tank, so as to improve leaching ability of the cyandidation and the adsorption intensity.

4.The aeration system and the trasmission system are innovated for the new model of the twin impeller high-effciency leaching agitation tank.

Technical parameters

| Model | Tank specifications (mm) D×L | Effective volume (m³) | Impelle | Diameter | Planet-cycloid reducer | total weight (kg) | ||||

Speed r/min | Diameter (mm) | Feed tube(mm) | Discharge tube (mm) | Model | Speed ratio | Motor power (kw) | ||||

| SJ2.0×2.5 | 2000×2500 | 6 | 52 | 909 | 2—Φ133×8 | 2—Φ133×8 | XLD2.2-4-29 | 29 | 2.2 | 2144 |

| SJ2.5×3.15 | 2500×3150 | 13.14 | 935 | 2—Φ133×8 | 2—Φ133×8 | 3095 | ||||

| SJ3.0×3.0 | 3000×3000 | 18 | 40.85 | 1130 | 2—Φ150 | 2—Φ150 | XLD4-5-35 | 35 | 4 | 4161 |

| SJ3×3.15 | 3000×3150 | 18.93 | 43 | 1130 | 2—Φ150 | 2—Φ150 | 4323 | |||

| SJ3.15×3.55 | 3150×3550 | 24 | 43 | 1260 | 2—Φ150 | 2—Φ150 | 4583 | |||

| SJ3.5×3.5 | 3500×3500 | 30 | 52 | 1310 | 2—Φ150 | 2—Φ150 | XLD5.5-5-29 | 29 | 5.5 | 5025 |

| SJ3.5×4.0 | 3500×4000 | 32.7 | 41 | 1310 | 2—Φ150 | 2—Φ150 | 5429 | |||

| SJ3.55×4.0 | 3550×4000 | 33.6 | 43 | 1310 | 2—Φ150 | 2—Φ150 | XLD4-5-35 | 35 | 4 | 5825 |

| SJ3.7×4.2 | 3700×4200 | 38.4 | 42 | 1310 | 2—Φ150 | 2—Φ150 | XLD4-5-35 | 43 | 4 | 6153 |

| SJ4.0×4.0 | 4000×4000 | 38 | 35 | 1750 | 2—Φ159×8 | 2—Φ159×8 | XLD7.5-7-43 | 43 | 7.5 | 7450 |

| SJ4.0×4.5 | 4000×4500 | 48 | 35 | 1750 | 2—Φ159×8 | 2—Φ159×8 | XLD7.5-7-43 | 43 | 7.5 | 7569 |

| SJ4.5×5.0 | 4500×5000 | 71.57 | 1750 | 2—Φ159×8 | 2—Φ159×8 | XLD7.5-7-43 | 43 | 7.5 | 10864 | |

| SJ5.0×5.6 | 5000×5600 | 98 | 31 | 2046 | 2—Φ159×8 | 2—Φ159×8 | XLD11-8-47 | 47 | 11 | 14291 |

| SJ5.5×6.0 | 5500×6000 | 112 | 2100 | 2—Φ159×8 | 2—Φ159×8 | 47 | 11 | 18745 | ||

| Φ6×6.5 | 6000×6500 | 170 | 24.9 | 2300 | 2—Φ168×8 | 2—Φ168×8 | XLD18.5-9-35 | 31.5 | 18.5 | 21006 |

| Φ6.5×7 | 6500×7000 | 215 | 23 | 2400 | 2—Φ168×8 | 2—Φ168×8 | XLD18.5-9-43 | 43 | 22 | 25567 |

| Φ7.0×7.5 | 7000×7500 | 245.4 | 21 | 2400 | 2—Φ168×8 | 2—Φ168×8 | XLD22-10-47 | 47 | 22 | 30486 |

| SJ7.5×8.0 | 7500×8000 | 268.6 | 21 | 2900 | 2—Φ168×8 | 2—Φ168×8 | XLD22-10-47 | 47 | 22 | 34365 |

| SJ8.0×8.5 | 8000×8500 | 342 | 16.4 | 3200 | 2—Φ219×8 | 2—Φ219×8 | Y250M-8 | 30 | 42468 | |

| Φ8.5×9 | 8500×9000 | 395 | 18.5 | 3300 | 2—Φ219×8 | 2—Φ219×8 | Y250M-8 | 30 | 46623 | |

| Φ9.5×10 | 9500×10000 | 648 | 16.6 | 3750 | 2—Φ273×8 | 2—Φ273×8 | Y280S-8 | 37 | 59786 | |

| Φ10.5×11 | 10500×11000 | 900 | 13.28 | 4400 | 2—Φ325×8 | 2—Φ325×8 | Y315S-8 | 55 | 72647 | |

| Φ11.5×12 | 11500×12000 | 1190 | 12.1 | 4600 | 2—Φ325×8 | 2—Φ325×8 | Y315M-8 | 75 | 95669 | |

| Φ12×13 | 12000×13000 | 1414 | 13.4 | 4600 | 2—Φ377×8 | 2—Φ377×8 | Y315L1-8 | 90 | 120635 | |

| Φ13×14 | 13000×14000 | 1740 | 10.7 | 5200 | 2—Φ377×8 | 2—Φ377×8 | JR125-8 | 110 | 148666 | |

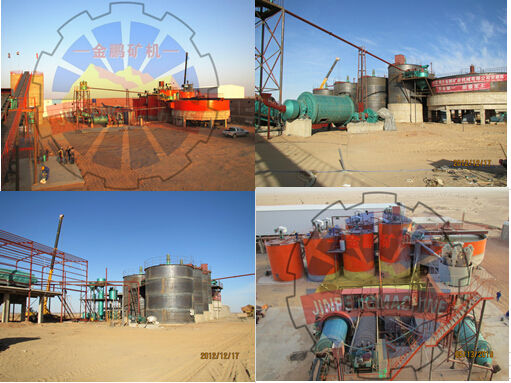

work onsite

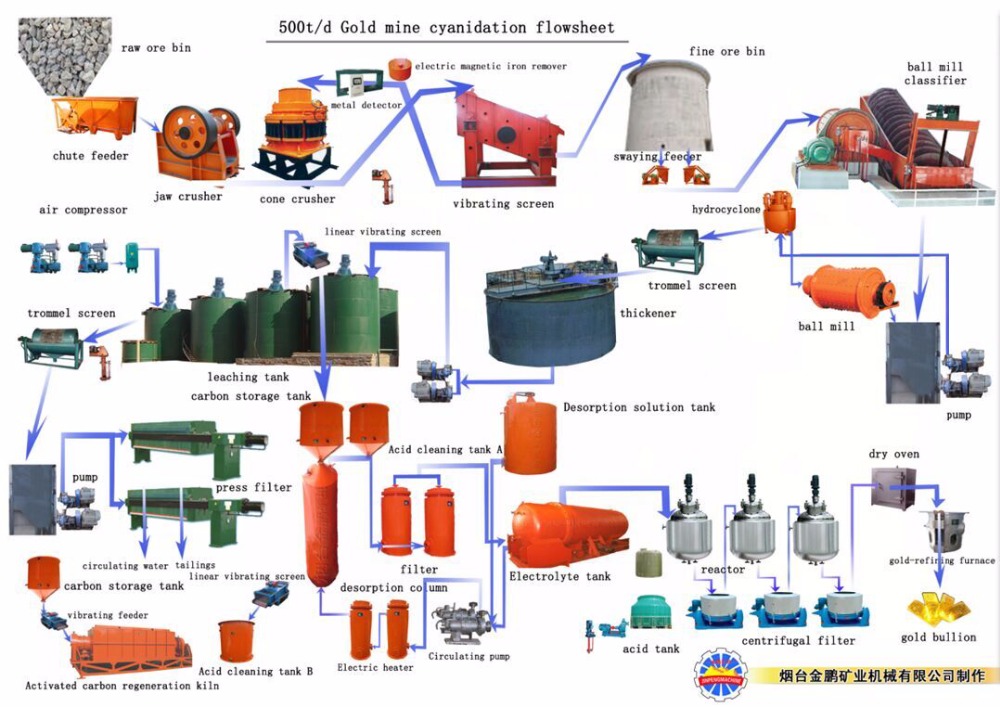

Used in gold process flowsheet

Customers around the world

Welcome to visit our company, and discuss the win-win cooperation!