6-9 ton/h Capacity Complete Organic Fertilizer Granules Production

- Категория: Compost Making Machines >>>

- Поставщик: Harbin,Dadi,Biology,Organic,Fertilizer,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-16-2025 | 3537066.85 $* | 3713919.12 $* |

| Aug-16-2025 | 3507342.27 $* | 3682709.60 $* |

| Jul-16-2025 | 2942601.39 $* | 3089731.76 $* |

| Jun-16-2025 | 3447896.7 $* | 3620291.43 $* |

| May-16-2025 | 3002047.75 $* | 3152149.29 $* |

| Apr-16-2025 | 3388449.6 $* | 3557871.49 $* |

| Mar-16-2025 | 3358726.87 $* | 3526662.45 $* |

| Feb-16-2025 | 3329003.53 $* | 3495453.40 $* |

| Jan-16-2025 | 3299280.89 $* | 3464244.96 $* |

Характеристики

6-8 ton/h Capacity Complete Organic Fertilizer Production Line

Capacity: 8 Tons per hour

Advantages of organic fertilizer production line

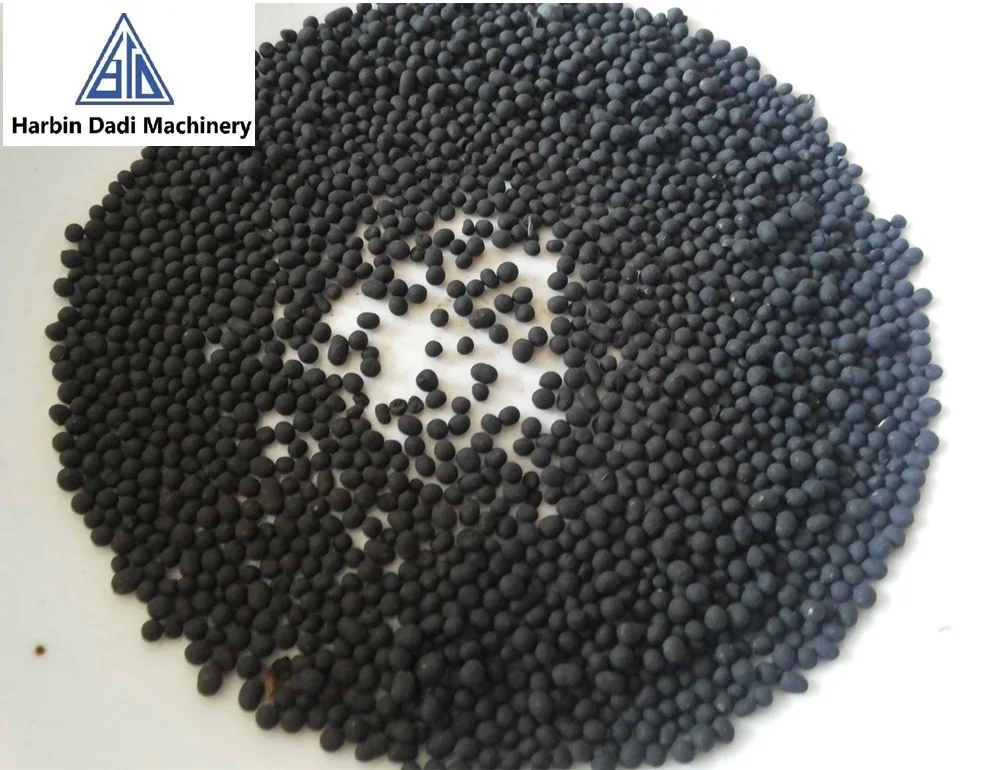

1) All the raw material can be made into ball shape.

2) The minimum rate of FINISHED product is 90%

3) The pellets have smooth surface,good hardness,not easily to be broken.

4) The organic content can be high to100%,make pure organic granulate.

5) No need to add binder when granulating.

| Machinery | Model | Sets |

| Semi-wet crusher | SWC-3 | 2 |

| Mixer machine(with pump) | DSM-3 | 1 |

| Ring Die Granulator | KHL-800 | 1 |

| Belt Conveyors | C-12 | 9 |

| Rotary Drum Dryer(cyclone dust collection+fan+pipeline) | RDD-7 | 1 |

| Rotary Drum Cooling(cyclone dust collection+fan+pipeline) | RDC-7 | 1 |

| Grading screen Machine | SGM-6 | 2 |

| Weighing&Packaging machine | WPM-500 | 1 |

We can add or reduce the equipments according to your requirements.

Raw Materials

The production line can make the following raw materials into granules :

1) Turfs, lignite, sludge, pond sludge,Sucrose slag,starch pulp.

2) Chicken manure, duck manure , pig manure , sheep dung , deer manure, cow dung and earthworm cast.

3) Bean cakes, Vinasse slag, Biogas residue, Fruit residue, palm oil residue.

4) Residues of urban rubbish or sewage treatment plants.

5) Organic materials mix with mineral materials .

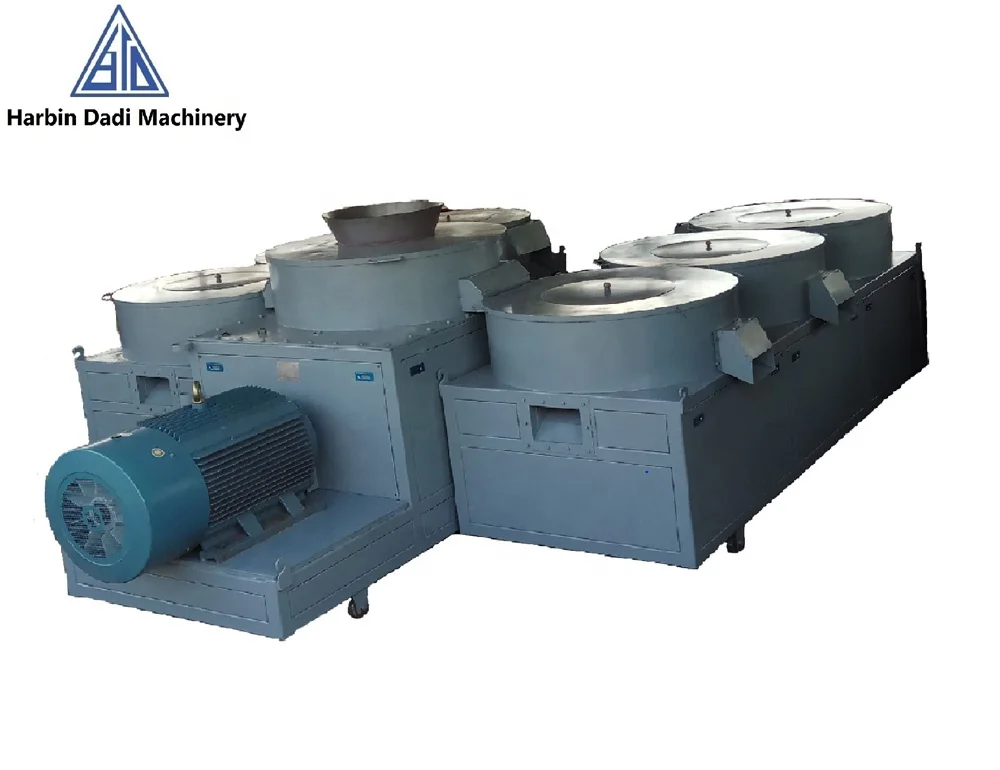

Ring Die Granulator

| Model | KHL-800 |

| Capacity:Tons per hour | 6-8 |

| Input material moisture:% | 30-35 |

| Input material particle size:mm | 0.3-0.5 |

| Rate of finish product:% | >90 |

| Pellet temperature raise:°C | <50 |

| Granule size:mm | 3.5-5.5 |

| Power:kw | 168 |

| Size:L*W*H (m) | 6.5*3.9*1.9 |

| Weight:Kgs | 10000 |

| Voltage:V | 380V-50HZ-3phase(it can be change under your need) |

Rotary Drum Dryer

| Model | RDD-7 |

| Capacity: Tons per hour | 6-8 |

| Temperature input required: | 200-300 °C |

| Temperature output: | 60 °C |

| Lifting impeller | Z type |

| Inclination | 1-1.5° |

| Revolving speed(r/min) | 3-8 |

| Size of Cyclone(m) | 1.8*1.5*4.5 |

| Diameter of pipeline(m) | 0.8 |

| Power (dryer) :kw | 30 |

| Power (fan):kw | 45 |

| Size:L*W*H (m) | 22*2.4*3.6 |

| Weight:Kgs | 18400 |

| Voltage:V | 380V-50HZ-3phase(it can be change under your need) |

Semi-Wet Crusher

| Model | SWC-3 |

| Capacity:T/h | 6-8 |

| Crushing particle size:mm | 0.5-5 |

| Power:kw | 22 |

| Size (L*W*H): m | 1.4*1.4*1.8 |

| Weight: Kg | 1200 |

| Voltage: V | 380V-50HZ-3Phase (it can be change under your need) |

Mixer

| Model | DSM-3 |

| Capacity:T/h | 6-8 |

| Revolving speed: r/min | 4 |

| Power: kw | 22 |

| Size (L*W*H): m | 3.5*1.6*1.1 |

| Weight:kg | 2400 |

| Voltage:V | 380V-50HZ-3Phase(it can be change under your need) |

Screening Machine

| Model | SGM-6 |

| Capacity:T/h | 6-8 |

| Revolving speed:r/min | 22 |

| Power:KW | 4 |

| Size (L*W*H):m | 5.5*1.7*2.2 |

| Weight: kg | 2400 |

| Voltage: V | 380V-50HZ-3Phase(it can be change under your need) |

Packing & Weight Machine

| Model | WPM-500 |

| Weighing accuracy | 0.2 x |

| Voltage:V | AC220V(-15%~+10%)-50Hz |

| Power: kw | 0.2kw |

| Portioning Range | 5-50 kg |

| Surrounding Temperature | -20~+40℃ |

| Power (Conveyor,package) | 2.2 kw |

| Power (weight) | 0.2 kw |

| Packaging speed |

5 kg:600 bag/ H,x(0.2) 10 kg:600 bag/ H,x(0.2) 50 kg:240 bag/ H,x(0.2) |

| LCL | FCL | |

| Way | Wooden cases with steel frame | Container |

| Packaging Details | The normal package is wooden box (Size:L*W*H).If export to european countries,the wooden box will be fumigated.If container is too tigher,we will use pefilm for packing or pack it according to customers special request. | Loaded into container |

1. Design the production line for you.

2. Design factory layout according to your requests and factory size.

3. Sample testing support.

4. Offering comprehensive technical and business consultation services.

5. Fast & Safe Delivery.

6. Training how to install the machine, how to use the machine and maintain.

7. Engineers available to service machinery overseas.

You can enjoy drawing design, equipment building, installation and running etc.full one-stop services from us.

Main products:

Organic fertilizer granulator machine /Organic fertilizer production line

Animal feed pellet machine

Biomass fuel pellet machine

Rotary drum dryer

Rotary drum cooler

Crusher

Grading screen machine

Certification

Похожие товары

Горячая продажа буксируемый Компост Тернер машина

Компост Тернер машина, гриб Компост Тернер машина

Данные ресурс не является интернет-магазином, а лишь содержит ссылки на международную торговую площадку Alibaba.com