Платиновый силиконовый каучук для формы пирожных в

- Категория: Rubber Raw Materials >>>

- Поставщик: Dongguan,Guochuang,Organic,Silicone,Material,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-19-2025 | 0.82 $* | 0.22 $* |

| Aug-19-2025 | 0.91 $* | 0.45 $* |

| Jul-19-2025 | 0.4 $* | 0.55 $* |

| Jun-19-2025 | 0.58 $* | 0.75 $* |

| May-19-2025 | 0.26 $* | 0.85 $* |

| Apr-19-2025 | 0.98 $* | 0.14 $* |

| Mar-19-2025 | 0.74 $* | 0.64 $* |

| Feb-19-2025 | 0.73 $* | 0.85 $* |

| Jan-19-2025 | 0.30 $* | 0.75 $* |

Характеристики

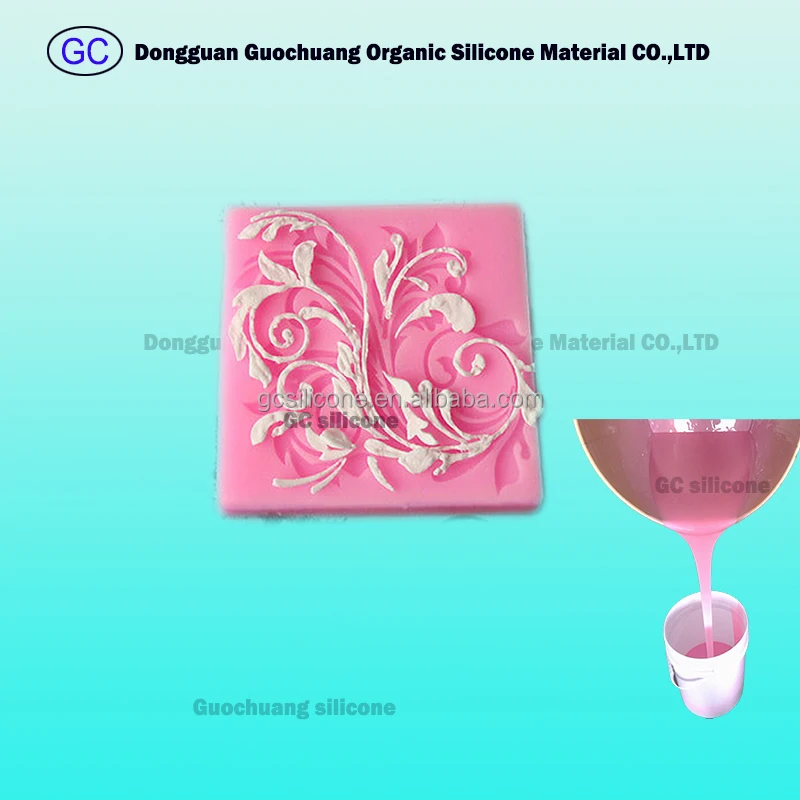

1.Description of Platinum 2 Parts Silicone Rubber For Food Rose Cake Molds

It is a kinds of Two-parts silicone, part A is flowable liquid silicon, part B is curing agent/ catalyst ,which gets cured at room temperature 25℃ within 3-6 hours or heating curing .This product is perfect for cement , concrete stone, GRC and GFRC products’ mold making,such as the flower pot , fountain,Polyurethane Wood Imitation,Reinforced Plastic,Garden Decorations ,fiberglass product and other decoration industries.

2.Characteristics of Platinum 2 Parts Silicone Rubber For Food Rose Cake Molds

Translucent silicone rubber

Very good heat resistance

High thermal conductivity

Outstanding resistance to common casting resins

Improved urethane and concrete resistance

Great fluidity

High tear strength

Nil shrinkage

Enhanced durability

3.Application of Platinum 2 Parts Silicone Rubber For Food Rose Cake Molds

Prototyping

Architectural Restoration

Sculpting/Wax Casting

Concrete/GRC Casting

Gypsum/Plaster Decoration

Resin Crafts Molding

Furniture Molding

Tire Molding

Low Melting Alloys

Ceramics MoldmaKing

Candles MoldmaKing

General Plastic Casting

4. Technical datasheet of Platinum 2 Parts Silicone Rubber For Food Rose Cake Molds

| Item No. | Appearance | Hardness (shore A°) | Viscosity (CPS) | Tensile-strength( kgf /cm2 ) | Tear-strength (kgf /cm2 ) | Elongation-break(%) | Mixing ratio | operation time (25 ℃ ) | Curing time( 25 ℃) | shrinkage |

| G-815 | translucent | 15±2 | 4000±1000 | ≥35 | ≥14 | ≥450 | 1:1 | 20-30 mins | 2~3 h | ≤0.1% |

5. NOTE:

Normally, different silicone should be chosen according to different product's features,for example :

- For products size (20cm-80cm),

with intricate designs, 20-25 shore A is suitable.

with simple designs, 25-30 shore A is suitable.

- For products size (80cm-150cm),

with intricate designs, 25 shore A is suitable.

with simple designs, 30-35 shore A is suitable.

- For products size (more than 150cm),

with intricate designs, 25-28 shore a A is suitable.

with simple designs, 35-40 shore A is suitable.

Packing:

20KG/drum vacuum packing for part A + 20KG/drum vacuum packing for part B

25KG/drum vacuum packing for part A + 25KG/drum vacuum packing for part B

200KG/drum packing for part A +200KG/drum packing for part B

Shipping

Dongguan Guochuang Organic Silicone Material Co., Ltd. established in 2003, is a Science and technology corporation which is engaged in production, R & D, and sales of silicone rubber and silicone mold. The HongKong GuoChuang silicone technology Co.,Ltd., other affiliated enterprises was set up in 2015.

We have passed ISO9001:2008 Quality Management System. Five main groups of members: R & D team which is rich in theoretical knowledge and work experience; Sales team who are proficient in several languages and with high level of business & after-sale service. With such a team, our silicone rubber was promoted to Southeast Asia, Europe, the Middle East , the America and etc, and our silicone rubber is well-received by the customers from more than 40 countries and regions; Production team has more than 10 years working experience. Our production team will totally follow the production control rule to meet the customer’s requirement; Quality Control team is our quality hero. We will follow the most strict quality stand for order shipping; The experienced mold making team who can custom-made molds to suit customer’s requirements.

Working with us ,you can have high quality and competitive price , and even the technical support and perfect after-sales service. We will offer the best solutions to promote both of our business and make the win-win situations.

FAQ:

1. Why will the silicone mold be reused only for a few times?

It can be due to the following reasons:

a. Adding too much silicone oil in to silicon rubber. Silicon oil is an additive which can destroy the molecular weight of silicone rubber and reduce the tension and tear strength.

b. Using the silicon rubber with a high hardness to make molds for small sized products with delicate and intricate designs or the silicon rubber with a low hardness to makes molds for large sized products with simple designs.

(Notes: we should choose the silicon rubber specifically according to the requirements of our products to avoid this problem.)

2. Why does the silicone mold appear to dry outside but wet inside?

Because molding silicone rubber is a kind of condensation silicone rubber, which get solidified after absorbing moisture from the air. In order to provide a significant shelf-life for the silicon rubber, we will dry out the water in the silicon rubber.

Solution: Add 0.1% water into the silicon rubber and Stir over a low speed briefly when you use it.

3. Why is the silicon mold oily?

The molding silicone rubber itself doesn’t contain any oil, so it won’t be oily. If the mold is oily, it may be because you add the compound silicone oil( the compound of silicon oil and white oil). The white oil is not silicon oil but a kind of petrochemicals.

(1) With us your money in safe, your business in safe.

(2) Free sample for testing.

(3) Competitive price.

(4) Strict Q/C (quality of control) management system.

(5) Enough production capacity and timely delivery.

(6) We support customized package and product.

(7) Prompt shipment with professional documents.

(8) Offering professional technical support.

(9) We can make confidentiality agreement with our customs.

(10) We will be here whenever you need.