Титановый анод высокого качества с покрытием

- Категория: Другой титан >>>

- Поставщик: Baoji,City,Changsheng,Titanium,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-16-2025 | 0.71 $* | 0.50 $* |

| Aug-16-2025 | 0.30 $* | 0.44 $* |

| Jul-16-2025 | 0.53 $* | 0.82 $* |

| Jun-16-2025 | 0.35 $* | 0.11 $* |

| May-16-2025 | 0.75 $* | 0.23 $* |

| Apr-16-2025 | 0.54 $* | 0.2 $* |

| Mar-16-2025 | 0.44 $* | 0.1 $* |

| Feb-16-2025 | 0.61 $* | 0.4 $* |

| Jan-16-2025 | 0.30 $* | 0.48 $* |

Характеристики

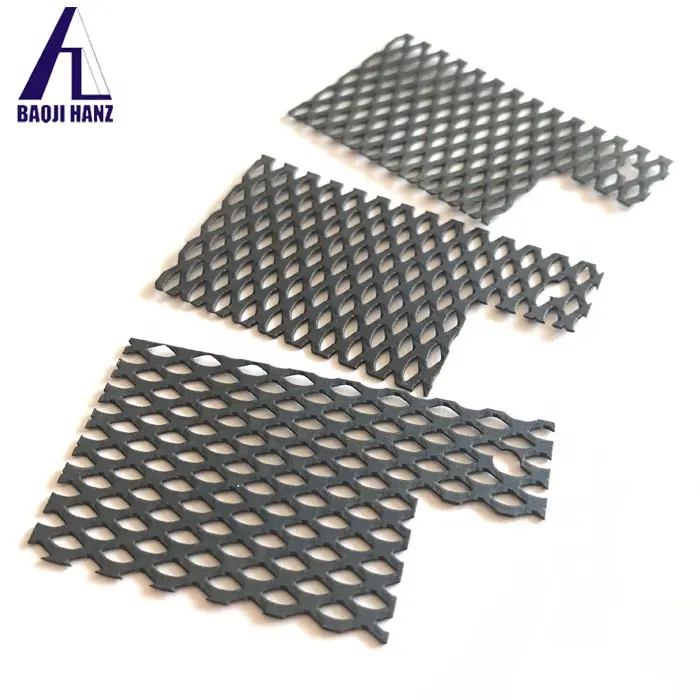

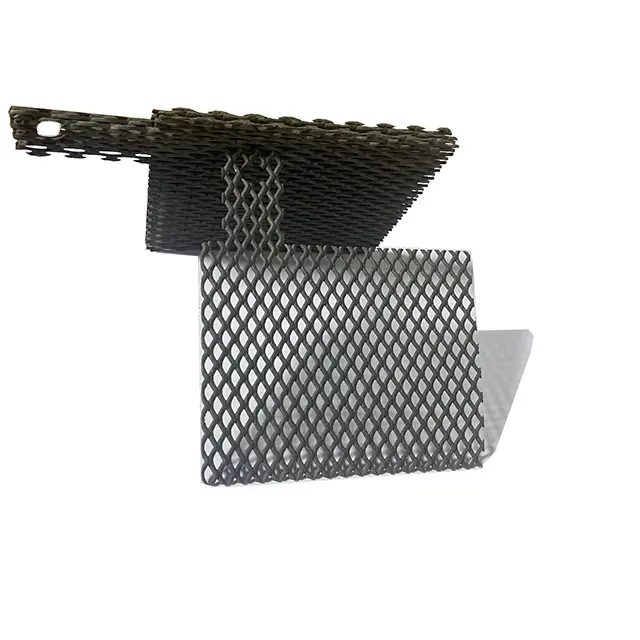

Ruthenium Oxide Coated Titanium Anode

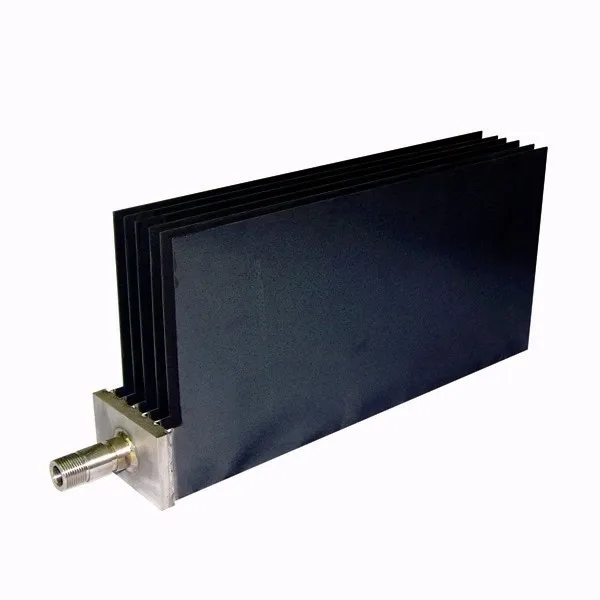

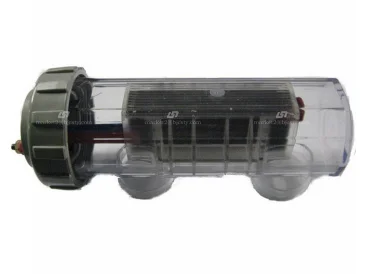

Titanium electrode (anode and cathode)

Titanium has in fact the features required in order to receive the coating, to resist the chemically aggressive environments of the processes and it's suitable for the current's conduction.Another advantage of Titanium is that it can be worked in a wide range of shapes: sheets, nets, tubes, wires, complex manufactured products etc.The electrode was born from the combination of coating and Titanium, which has afterwards taken different commercial names: DSE - DSA - MMO etc...

According to the classification of electrochemical reaction precipitation gas,insoluble anodes cna be divided into :chlorinated anodes ,oxygen-deoxidized anodes and oxychlorinated anodes,Ruthenium oxide coated titanim anode belongs to the chlorination anode .

Application case :

| Treatment: pretreatment system +A/O+ two-stage electrochemical +A/O COD content: 1600mg/L Ammonia nitrogen content: 2000mg/L Coating :Ru oxide Result:COD degradation to 160 (mg/L) below, total nitrogen degradation to 60 (mg/L) below, heavy metal ions also reached the role of degradation

|

| Titanium Substrate | Grade | N | C | H | Fe | O | Ti |

| 1 | 0.03 | 0.08 | 0.015 | 0.2 | 0.18 | bal | |

| 2 | 0.03 | 0.05 | 0.015 | 0.3 | 0.25 | bal | |

| Regular Coating | Pure Ruthenium coating | ||||||

| Coating contents & life span | 8 grams/m2: >6,000 hours; 10 grams/m2: > 8,000 hours; 12 grams/m2: >10,000 hours; 15 grams/m2: >12,000 hours; 20 grams/m2: >15,000 hours | ||||||

| Applications | 1. Non-ferrous metal electrolysis production, 2.Chloride electrolysis 3.Seawater electrolysis, 4.Metal foil manufacturing, 5.Metal foil surface electrochemical treatment, 6.Non-ferrous metal electrolysis extraction and recovery, 7.Organic electrolysis, 8.Cathodic protection etc | ||||||

Our control :

We have many years of experience in the research and development of electrochemical materials, there is a domestic metal corrosion and protection experienced technical director led by the technical team

Our test :

NO | Test Items | Standard | Result |

1 |

| No stains, indentation and impurities | Pass |

2 | Binding force | Transparent adhesive tape | No peeling at the bend |

3 | bullion content | ≥10g | 11 |

4 |

| ≤1.14 | 1.12 |

5 | Chlorine evolution polarizability MV | ≥40 | 38.5 |

6 | strengthening lifetime Min | HG/T2471-2001(≥3000) | >4000 |

Test conditions | (1)Electrolyte composition:Sulfuric acid electrolyte (AR).electrolyte :0.25mol/L (2)(2)Test temperature :20-40℃ (3)(3)electric current density:20000A/m2 (3)Tank voltage:4.2-15V | ||

Our Equipment :

Our company

ISO 2001: 9000

We advocate and fulfill modern management spirits to the corporation. Our quality management system is executed in accordance with ISO9001:2000 strictly. All exported products are followed in international ASTM standards, which effectively guarantees the quality and delivery of the products.

FAQ