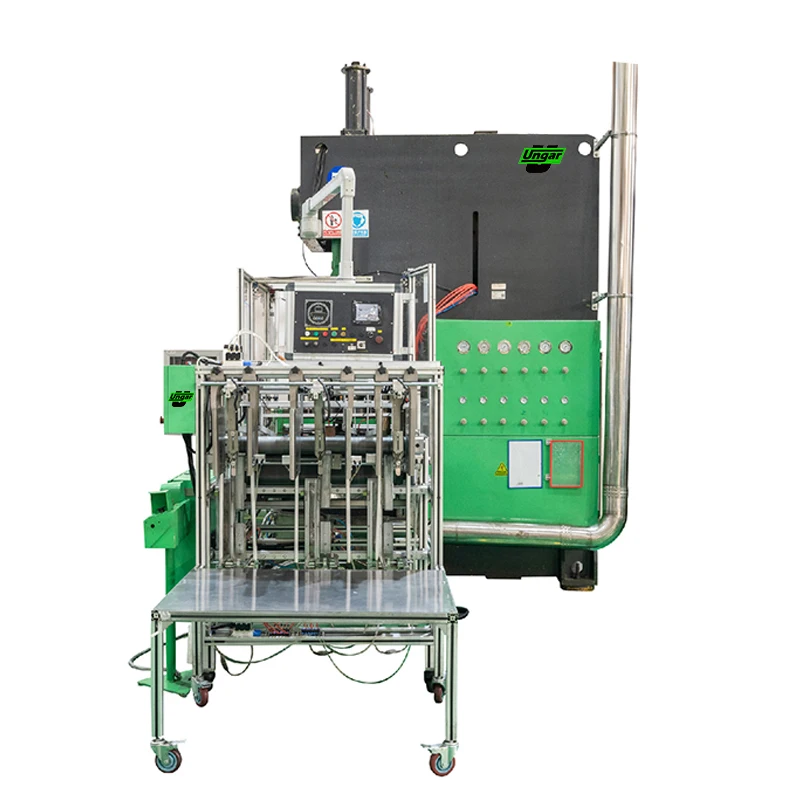

Ungar вертикальная машина для производства пищевых контейнеров из алюминиевой фольги на

- Категория: Other Home Product Making Machinery >>>

- Поставщик: Ungar,Machinery,(Shanghai),Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-15-2025 | 67830.46 $* | 71222.35 $* |

| Aug-15-2025 | 67260.64 $* | 70623.7 $* |

| Jul-15-2025 | 56430.51 $* | 59252.63 $* |

| Jun-15-2025 | 66120.19 $* | 69426.31 $* |

| May-15-2025 | 57570.8 $* | 60449.36 $* |

| Apr-15-2025 | 64980.62 $* | 68229.49 $* |

| Mar-15-2025 | 64410.89 $* | 67631.70 $* |

| Feb-15-2025 | 63840.48 $* | 67032.93 $* |

| Jan-15-2025 | 63270.65 $* | 66434.85 $* |

Характеристики

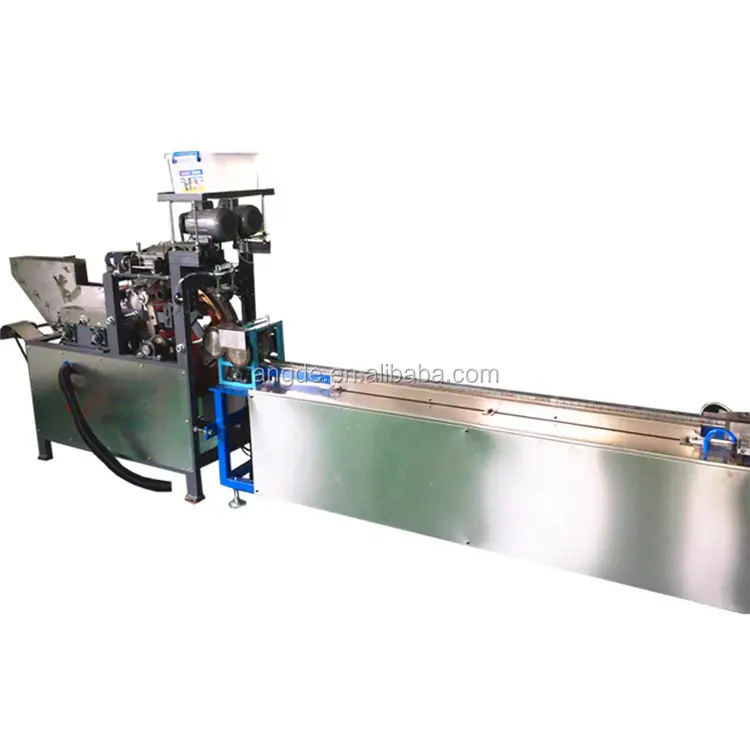

The operator of the machine only has to set up the packaging requirement(pcs to count)at the touch screen and collect the finished counted and stached products on the end of the line.

| Nominal force | 630KN,C-Type Press |

| Stroke time | 20-80 times/ Min. |

| Slide block stroke(Optional Size ) | 200/220/240/260mm(Option) |

| Max.height of mould installation | 420/450mm |

| Height adjustment for mould | 80mm |

| Distance from slide block center to body | 550mm |

| Adjustable work block dimension X2 | 1000(L)x200(W)x300(H)mm x2 |

| Dimension of Slide block bottom surface | 360x480mm |

| Hole Dimension Slide block bottom surface | 320-325x380mm |

| Size of centering hole(Diameter×Depth) | Φ60x80mm |

| Press Machine Type | Electric shut hight adjustment |

| Press Net Weight | 8,000KG |

| Voltage &Frequency(Optional) | 380V - 50/60Hz - 3 Phase |

| Total power | 11kW |

| Press dimension (LxWxH) | 2200x1300x3600mm |

Advanages:

2. Main motor is made by Siemens.

3. Adopts combined pneumatic friction clutch and brake.

4. Cluster gear adopts the flooding oil lubrication.

5. Six-face rectangle lengthen guide;

6. Equipped with hydraulic overload protecting device.

7. Electric shut height adjustment with digital display.

8. Equipped with lifting balance cylinder.

9. Duplex valves imported.

10. Electric compelling grease lubrication system.

11. Balancing cylinder adopts manual lubrication system.

12. One set of blowing device.

UNGAR Machinery (Shanghai) Co., Ltd is an Austrian enterprise established in 2009, supplying high productive multi-cavity moulds and machines, which includes press, stacker, package, re-winder, paper lid cutting, decoiler, scrap press and additional equipments.

UNGAR complete integrated production line has been specially designed and developed for the production of aluminum foil food container, plate and household foil rolls.

UNGAR Machinery (Shanghai) Co., Ltd also offer customized service for technical optimization, mould prove, machine installation, material test, training course, telephone assistance and so on.