100% биоразлагаемые формы для

- Категория: Moulds >>>

- Поставщик: Xiamen,Ecson,Technology,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-16-2025 | 0.18 $* | 0.49 $* |

| Aug-16-2025 | 0.74 $* | 0.47 $* |

| Jul-16-2025 | 0.13 $* | 0.59 $* |

| Jun-16-2025 | 0.18 $* | 0.53 $* |

| May-16-2025 | 0.76 $* | 0.10 $* |

| Apr-16-2025 | 0.78 $* | 0.18 $* |

| Mar-16-2025 | 0.48 $* | 0.63 $* |

| Feb-16-2025 | 0.5 $* | 0.98 $* |

| Jan-16-2025 | 0.36 $* | 0.48 $* |

Характеристики

2.Easy to install and will not crack, crumble, or warp.

3.excellent in quality and high strength

4.Many attractive designs, nice appearance

5. A great deal of experience in export

6.Standard packing

7.24-hour service, contact us anytime you like

8.Over the years , we have won the praise of many consumers relying on our superior products and service

9.Factory directly supplying

Plastic injection mould made

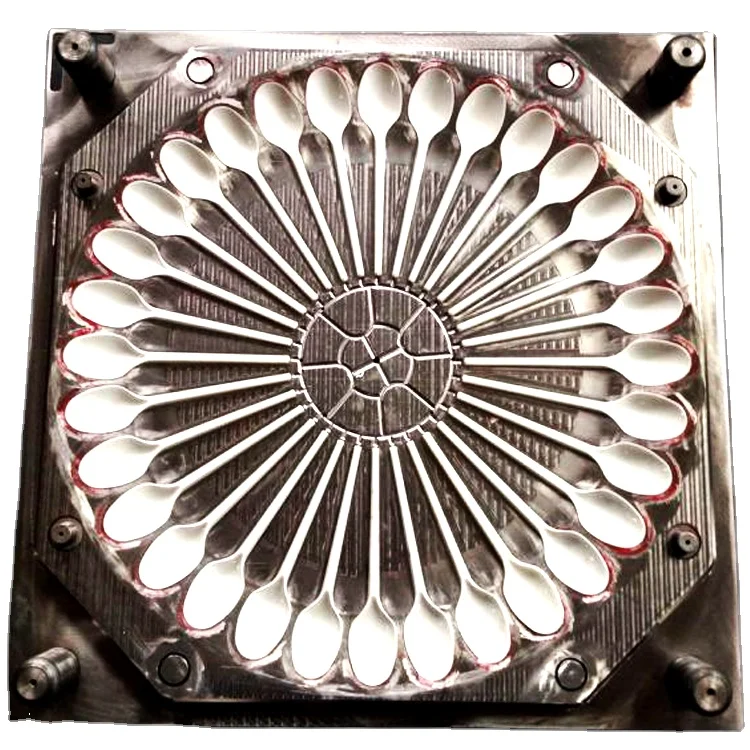

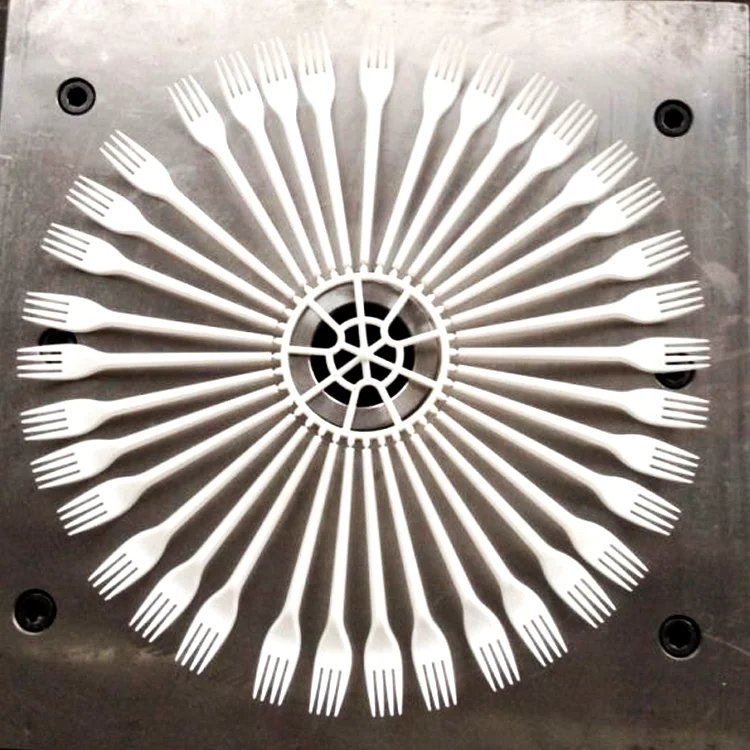

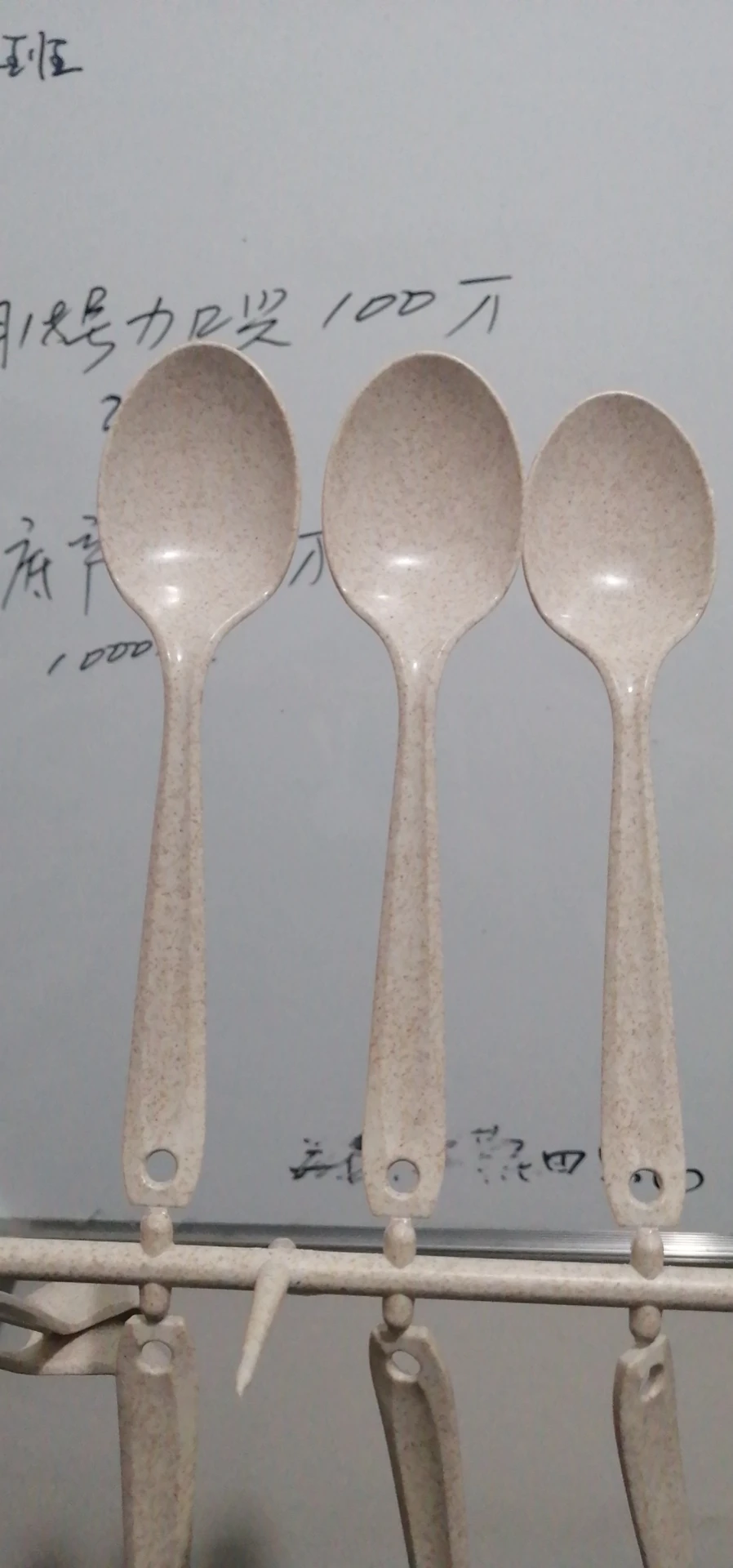

Product name | disposal 100% biodegradable PLA cutlery mould fork knife spoon mould PLA mould spoon injection mold and molding | |||||

Equipments | CNC discharge machines, drilling machines, grinding machines, injection moulding machines and all kinds of processing equipments | |||||

Acceptable file formats | 2D: AutoCAD, PDF 3D: igs, stp(step), UG, Pro.E, SolidWork | |||||

Mould base | LKM,HASCO, DME, MISUMI, or by requested etc. | |||||

Mold System | Hot runner, Cold runner | |||||

Mold cavity material | NAK80,S136,718H, P20, NAK80, 2316, 2738, 2344 | |||||

Mold lifetime | Depands on customers' request and the customers' option for mould steel | |||||

Lead time | Depands on mould construcstion | |||||

One stop service :Design 3D mould drawing - mould make-plastic injection molding-second processing- assembly - package - shipment - after-sales service | ||||||

PRECISION MOULD

Product tolarance can controlled to be +_0.02

COMPLEX MOULD

Complex mould is no a problem for us,our team like the hard job!Here we had mould for 72 sliders!

MOULDING MATERIAL

The materials are highly controlled ,the material for electronics parts also request to be fire resistance

Ecson Tech Co., Ltd is a group corporation, specializing in quality-focused manufacturing investment and management.

Supporting innovative companies accross mechanism, plastics & electronic related industries. The available and values demonstrated include innovation design.

Manufacturing excellence, personal development, quality control, marketing and customer service. Ecson including 3 different factories Ecson Plastics Co. Ltd, Ecson Electronics Co., Ltd, Homey Innovation Co., Ltd

With years of export experience along with excellent quality, advanced services and competitive prices, Ecson has won numerous customers' trust and support.

About us

1, Cover an area of 20000 Square Meters,Have 20 years rich experience in manufacturing plastic injection mould, plastic and rubber products,150 professional staffs with professional engineers in the technical research and development department

Equipment & technology

2, 35 sets of injection machines,largest injection can be 2meters,with precision machines and strong R&D capability

Service

3, stable product quality , supply, the good faith management

Q1:I have an idea for a new product, but don't know if it can be manufactured. Can you help?

A1:Yes! We are always happy to work with potential customers to evaluate the technical feasibility of your idea or design and we can advise on materials, tooling and likely set-up costs.

Q2:What are the advantages to having my parts manufactured locally?

A2:Ecson can offer quick reaction times to any changes in specification, batch size or material. We can ship small or large quantities anywhere in Europe overnight to accommodate unforeseen changes in demand.

Q3:My components have already been developed on CAD. Can you use the drawings?

A3:Yes! DWG, DXF, IGES, Solidworks and Rhino files can all be used to generate quotes, models and mould tools - this can save time and money in producing your parts.

Q4: Can I test my idea/component before committing to mould tool manufacture?

A4: Yes, we can use 3D drawings to make models for design and functional evaluations.

Q5: What type of plastic is best for my design/component?

A5:Materials selection depends on the application of your design and the environment in which it will function. We will be happy to discuss the alternatives and suggest the best material.

Q6.What type of mould tool do I need?

A6: Mould tools can be either single cavity (one part at a time)or multi(2,4, 8 or 16 parts at a time). Single cavity tools are generally used for small quantities, up to 10,000 parts per year whereas multiavity tools are for larger quantities. We can look at your projected annual requirements and recommend which would be best for you.

Q7. What shall we do if we do not have drawings?

Please send your sample to our factory,then we can copy or provide you better solutions. Please send us pictures or drafts with dimensions(Length,Hight,Width),CAD or 3D file will be made for you if placed order.

Q8. Can we get some samples before mass production?

A8:Absolutely yes,the mass production will according approval sample

Q9. Will my drawings be safe after sending to you?

A9:Yes, we will keep them well and not release to third party without your permission.

And we can sign Non-disclosure agreement with customers

Q10 What is the largest tons for injection machine

A10:Our largest injection machine is 800Tons

Q11 I've decided to go ahead with my project. How long will it take to get my parts?

A11. It can take4- 6weeks to have the mould tool manufactured depending on the part's complexity and the number of impressions (single or multi). After we have received final approval by you of the new tool, you can expect delivery of parts within 3-5 days.