Механические детали кремниевый карбид SIC керамический винтовой

- Категория: Refractory >>>

- Поставщик: Zhengzhou,Honesty,Refractory,Co.,Ltd.,[Henan,China]Zhengzhou

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Aug-18-2025 | 169.61 $* | 172.98 $* |

| Jul-18-2025 | 137.34 $* | 140.62 $* |

| Jun-18-2025 | 166.22 $* | 169.72 $* |

| May-18-2025 | 165.52 $* | 168.89 $* |

| Apr-18-2025 | 132.98 $* | 135.11 $* |

| Mar-18-2025 | 162.89 $* | 165.52 $* |

| Feb-18-2025 | 161.93 $* | 164.46 $* |

| Jan-18-2025 | 160.7 $* | 163.50 $* |

Характеристики

Mechanical Parts Silicon Carbide SIC Ceramic Screw Nut Boltate

Reaction Boned Silicon Carbide(RBSiC or SiSiC) ceramics adopt slip-casting technology. The Ceramics have high strength and excellent hardness, wear, corrosion resistance, oxidization resistance and thermal shock resistance, etc. It's one of the most popular refractory ceramics. It can be made to beams, rollers, cooling air pipes, thermal couple protection tubes, sealing parts and special shaped parts.

RBSiC (SiSiC) products,silicon carbide buner nozzles can be used in tunnel kiln, shuttle kiln, roller hearth kiln and other industrial kilns of gas, fuel oil. They are widely used and adopted by domestic and foreign kiln companies.

The silicon carbide burner tube cam be used in tunnel kiln, shuttle kiln, roller hearth kiln and other industrial kilns of gas, fuel oil.

1, very low wear and tear and can prevent material pollution.

2,suitable for a variety of grinding and dispersion occasions.

3, high grinding efficiency.

4, extremely long service life and the integrated cost is lower than others

Performance Table silicon carbide ceramic pipe sleeve ceramic

item | unit | data |

temperature of application | C | 1380 |

density | g/cm3 | >=3.02 |

open porosity | % | <0.1 |

bending strength | Mpa | 250(20C) |

Mpa | 280(1200C) | |

modulus of elasticity | Gpa | 330(20C) |

Gpa | 300(1200C) | |

thermal conductivity | W/m.k | 45(1200C) |

coefficient of thermal expansion | K-1*10-6 | 4.5 |

rigidity |

| 13 |

Mohs hardness | 9.6 | |

acid-proof alkaline |

| Excellent |

ssic ceramic pipe sleeve

item | unit | data |

temperature of application | C | 1700 |

density | g/cm3 | >=3.05 |

open porosity | % | <0.1 |

bending strength | Mpa | 400-580 |

modulus of elasticity | Gpa | 380-410 |

thermal conductivity | W/m.k | 102.6 |

coefficient of thermal expansion | K-1*10-6 | 4.2 |

Mohs hardness | 9.6 | |

acid-proof alkaline | Excellent |

We can customize the bushing insulators when you send us the size or drawing do you want.

If you want it,please contact us.We can supply you the samples do you want.

1. Can you accept OEM?

Yes!.We can manufacture as per your request specification.

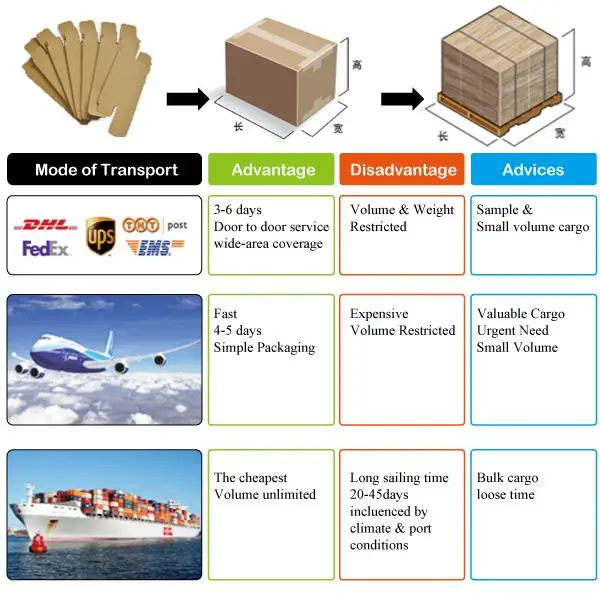

2. Can you deliver the goods via our shipping agent?

Yes, we could help you make the delivery using your shipping agent

3. Can you supply sample?

Yes.We would like to give you suitable suggestion according to your detail application.

4. What about your After-sales service?

Yes.We promise that we can change or refund products if there are any quality problem.

Warmly welcome your inquiry

Похожие товары

Данные ресурс не является интернет-магазином, а лишь содержит ссылки на международную торговую площадку Alibaba.com