Стеллаж для поддонов склада селективный стеллаж Прочная Система от

- Категория: Stacking Racks & Shelves >>>

- Поставщик: Xiamen,Luckyroc,Industry,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-17-2025 | 0.49 $* | 0.38 $* |

| Aug-17-2025 | 0.86 $* | 0.53 $* |

| Jul-17-2025 | 0.58 $* | 0.88 $* |

| Jun-17-2025 | 0.68 $* | 0.63 $* |

| May-17-2025 | 0.67 $* | 0.25 $* |

| Apr-17-2025 | 0.38 $* | 0.40 $* |

| Mar-17-2025 | 0.84 $* | 0.98 $* |

| Feb-17-2025 | 0.45 $* | 0.41 $* |

| Jan-17-2025 | 0.82 $* | 0.97 $* |

Характеристики

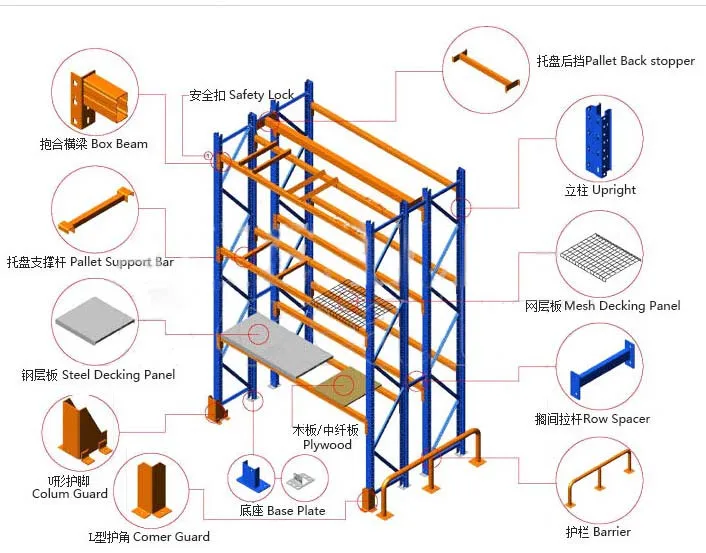

Warehouse storage selective pallet rack US teardrop durable pallet racking system from China supplier

Selective Pallet Racking is by far the most common type of warehouse storage rack and is what is typically thought of when the need arises for industrial type storage racking. All selective rack is made from component pieces that are usually priced & purchased separately.

1) 16 years of experience producing steel warehouse racks.

2) Professional technical team and sales team with more than ten years experience

3) Own many advanced rolling line and automatic powder spaying line.

4) Clients of Luckyroc:PHILIPS,DELL,ABB,HONDA,LINDE,XIAMEN AIRLINE,TPV,LENOVO.

Luckyroc Company could provide various kind of racking system according to customer's request,

including Shuttle Racking, Pallet Racking, Push Back Racking, Drive in Racking, Gravity Racking,

Cantilever Racking, Shelf Racking, Mezzanine Racking,ASRS,and so on.

1. Shuttle Racking: The pallets are moved by shuttle machine, and the design is similar as drive in racking;

2. Pallet Racking: The simplest and widest used racks, suitable for stocking various kinds of goods;

3. Push Back Racking: Combine the advantages of both drive in racking and gravity racking;

4. Drive in Racking: High usage of warehouse, FIFO and FILO are available,

5. Gravity Racking: FIFO Way, goods are mobile, especially suit for the perishable & Volume Goods;

6. Cantilever Racking: Suitable for storage of long and irregular shape good such as long tubes and wire;

7. Shelf Racking: Suitable for scattered and portability goods, usually worked by man;

8. Mezzanine Racking: High usage up to several fold of ground area, could be built on the shelf racking.

9.ASRS: Automated Storage & Retrieval System, consists of hard storage rack system, crane and soft computer-controlled system

1. Question: Are you a trade company or manufacture factory?

Answer: We are a manufacture factory;

2. Question: Where is your factory?

Answer: Our factory is located in Xiamen city which is face to face Taiwan;

3. Question: What is your steel material?

Answer: The material is Steel Q235 which is similar as SS400;

4. What is your payment terms?

We accept T/T and L/C, other terms could be further discussed;

5. Do you have any request about the order quantity?

Any order quantity is accepted. But small order would take more shipping cost;

6. How could you guarantee the products quality?

We have professional engineer to check what size should be used to guarantee your load weight request.

Before shipping, our quality control also would carefully check whether the quality is approved.

7. How could I install the racks?

We would provide detail install drawing to teach you how to install the racks. If needed, we also could providefree engineer to teach you installation. But related cost( Flight, living and eating) should be in your charge.

Please inform us of the following information for quick quotation:

1. | drawing(if available) |

2. | size of your warehouse |

3. | size of rack(height*width*depth) |

4. | how many levels of the rack |

5. | loading capacity of each level |

6. | (RAL)color you want |