3 ролик сталь листовая пластина роликовая листогибочная машина с W11 из листового металла гибочного

- Категория: Bending Machines >>>

- Поставщик: Anhui,Runbang,Heavy,Industry,Machinery,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-17-2025 | 4022.71 $* | 4223.94 $* |

| Aug-17-2025 | 3988.50 $* | 4187.7 $* |

| Jul-17-2025 | 3346.67 $* | 3513.52 $* |

| Jun-17-2025 | 3921.71 $* | 4117.37 $* |

| May-17-2025 | 3414.78 $* | 3585.93 $* |

| Apr-17-2025 | 3853.60 $* | 4046.64 $* |

| Mar-17-2025 | 3819.17 $* | 4010.45 $* |

| Feb-17-2025 | 3786.0 $* | 3975.95 $* |

| Jan-17-2025 | 3752.37 $* | 3940.48 $* |

Характеристики

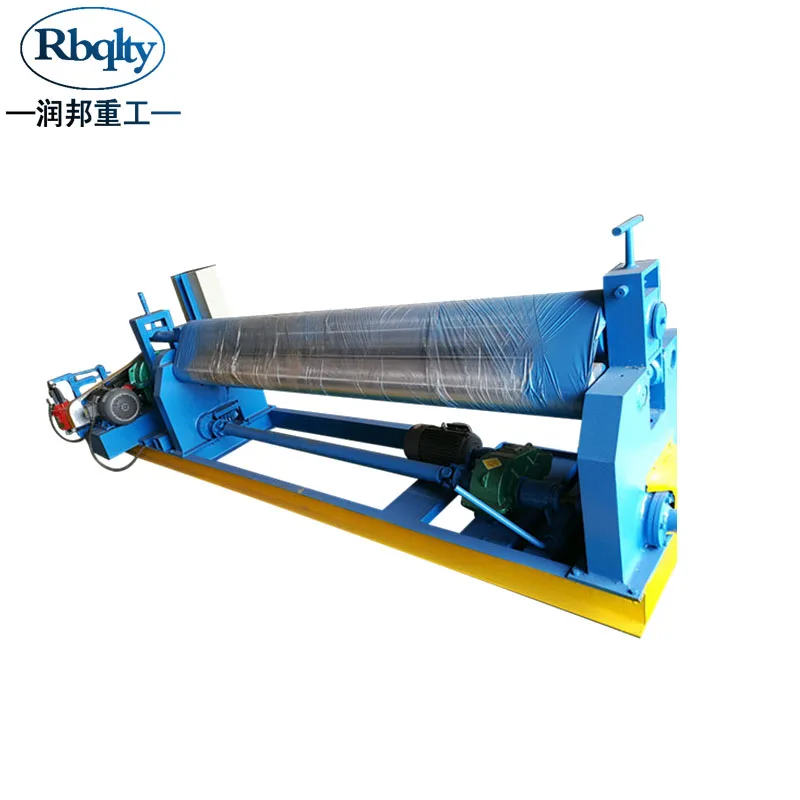

Factory Quality Rolling Bending Machine W11 Steel Plate Rolling Machine

1. Main power:Siemens Electrical made in Germany

2. Main electronic elements: Schneider made in France;

3. Axletree:Double-row self-aligning bearingfrom Germany

4. Main motor: Siemens Electrical made in Germany

5. Programmable logic controller PLC:OMRON products from Japan

6. Hydraulic system: Bosch – Rexroth made inGermany

7. Gear pump: made in China TaiWan ;

8. Work Roller:Material of work roller with 42CrMo Alloy steel.

9. Digital display system:Touch Screen for Delta

10 Transducer:OMRON,Made in Japan

11. Automatic lubrication system:Sino-Japanese joint,which has block alarm

FACTORY QUALITY ROLLING BENDING MACHINE DETAILS

ROLLER BENDING MACHINE PRODUCTION PROCESS

Upper roll device

The up roller gear drive from the main for turning, the ends of the SP-1 bearing support, drive-side through the flat key, off the main drive gear and connect the device to transfer torque, tip-side with the protection of Steel . The material of the up roller is 42CrMo, heat hardening is HB220-300.

main drive device:

By the Hydraulic motor, three speed reduction gear, transmission torque to the up roller. This device include motors and speed reduction gear box. Power supply is according to customer's requirement

Down roller device:

Down roller supports under the bearing, the bearing housings on both sides of the rack mounted inside the track, the bottom of the piston and cylinder connected. Bearing in the liquid under pressure can rise and fall along the rail, according to the size of the thrust rod, steel plate under the roller clamping force required by the hydraulic system pressure control valve be adjusted. Addition of the down lower rollers can roll adjustment, improve the accuracy of product under the same material as the roll quality alloy steel 45#, heat treatment hardening is HB220-300

Side roller device:

Side of the roller bearing in the radial bearing pedestal, bearing on both sides of the rack mounted inside the track, the bottom of the piston and oil cylinder connected. Bearing in the liquid under pressure, can be tilted up and down along the rail, the size of the piston rod of the thrust force according to the needs of steel plate by the hydraulic system pressure control valve be adjusted. The side roll quality alloy steel, heat treatment hardening is HB220-280.

Overturn device:

Overturn device through the oil cylinder , hinges torn off and driving overturned on a roller bearing aircraft overturned in order to remove products.

ROLLER BENDING MACHINE ENDING PRODUCTS

* Expert in kinds of sheet metal processing machines, like bending machine, shearing machine, iron worker, hydraulic press, punching machine, duct manufacturing auto line, cutting machine and so on

* With an expert team in R&D for more than 20 years, occupied the work shop of over 30,000 square meters, Runbang is able to support you with best quality machines

* With CE/ISO/SGS certification

1:How can I choose the most suitable machines ?

A: Please tell me your specifications ,I can choose the best model for you , or you can choose the exact model .

You can also send us the products drawing ,we will choose the most suitable machines for you .

2: What's your main products of your company?

A: We focus on variety serious of machine, such us hydraulic press machine, punching machine, bending machine, shearing machine, ironworker, auto duct line and so on .

3: Where is our factory located? How can I visit there?

A: Our factory is located in Maanshan City, Anhui Province, 40 mins drive to Nanjing Lukou Airport. You are warmly welcomed to visit us.

4. What is your trade terms?

A: FOB, CFR and CIF all acceptable.

5: What's the Payment Terms ?

A: T/T ,30% initial payment when order ,70% balance payment before shipment ;

5: What's the MOQ?

A: 1 set .(Only some low cost machines will be more than 1 set )

Any interest, pls feel free to contact us:

Anhui Runbang Heavy Industry Machinery Co.,Ltd