TONTEN огнеупорные покрытия для потерянных пенопластовых отливок или EPS

- Категория: Other Fabrication Services >>>

- Поставщик: Gongyi,City,Tonten,Abrasive,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-20-2025 | 0.40 $* | 0.39 $* |

| Aug-20-2025 | 0.54 $* | 0.17 $* |

| Jul-20-2025 | 0.96 $* | 0.25 $* |

| Jun-20-2025 | 0.60 $* | 0.13 $* |

| May-20-2025 | 0.24 $* | 0.0 $* |

| Apr-20-2025 | 0.94 $* | 0.39 $* |

| Mar-20-2025 | 0.59 $* | 0.79 $* |

| Feb-20-2025 | 0.66 $* | 0.91 $* |

| Jan-20-2025 | 0.30 $* | 0.71 $* |

Характеристики

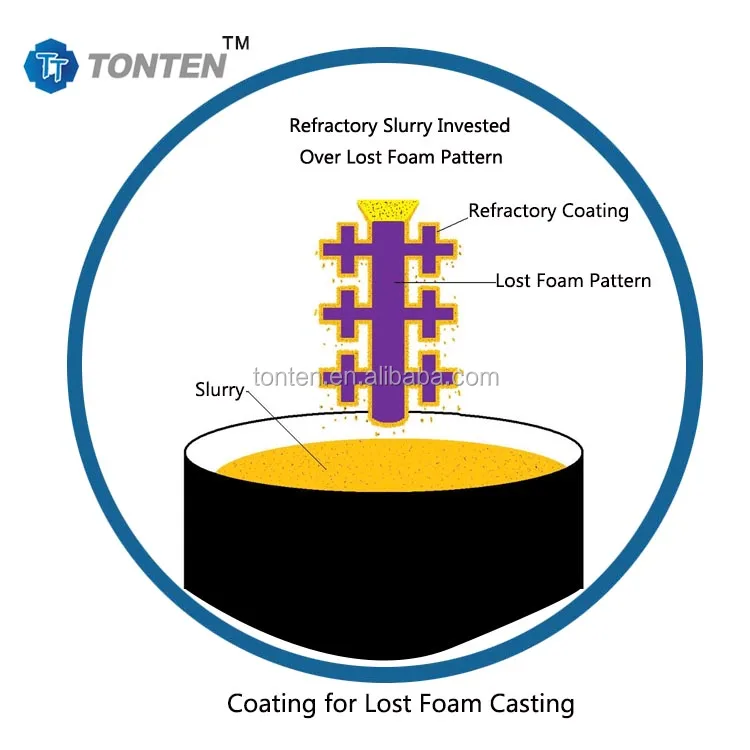

Lost Foam Casting (LFC) is a type of evaporative-pattern casting process that is similar to investment casting except foam is used for the pattern instead of wax. This process takes advantage of the low boiling point of foam to simplify the investment casting process by removing the need to melt the wax out of the mold.

Next, the foam cluster is coated with ceramic investment, also known as the REFRACTORY COATINGS, via dipping, brushing, spraying or flow coating. This coating creates a barrier between the smooth foam surface and the coarse sand surface. Secondly it controls permeability, which allows the gas created by the vaporized foam pattern to escape through the coating and into the SAND. Controlling permeability is a crucial step to avoid sand erosion. Finally, it forms a barrier so that molten metal does not penetrate or cause sand erosion during pouring. After the coating dries, the cluster is placed into a flask and backed up with un-bonded sand. The sand is then compacted using a vibration table. Once compacted, the mold is ready to be poured.Automatic pouring is commonly used in LFC, as the pouring process is significantly more critical than in conventional foundry practice.

There is no bake-out phase, as for lost-wax. The melt is poured directly into the foam-filled mold, burning out the foam as it pours. As the foam is of low density, the waste gas produced by this is relatively small and can escape through mold permeability, as for the usual outgassing control.

Established in 2009, GONGYI TONTEN ABRASIVE CO., LTD is a professional manufacturer and exporter for followings:

-Abrasive Material (corundum/ fused alumina, garnet, copper slag, silicon carbide, dustless or soft sandblasting media, etc.)

-Refractory Material (refractory brick/ball, castable material,bubble alumina,cenosphere, silicon carbide, etc.)

-Foundry Material (ceramsite, silica sand, lost foam/ V-Process casting coating, EPS foam mending paste, etc.)

-Filter Material (silica sand, ceramsite, ceramic sand, walnut shell, garnet, PAC, etc.)

-Chemical Products (Synthetic Cryolite, PAC, Alumina Oxide, fused silica etc.)

-Wear resistant Products (Grinding balls, crusher wearing parts, etc.)

Packing Details : 25kg/polywoven bag or as requirements

Delivery Details : 3-25 days after payment

Overseas friends from India

Shymal and his workmate visited our black fused alumina workshop, they speak highly of our product quality.

Keyword: fused alumina,

Regular Size: 24#, 30#, 36#, 60#, 80# , etc.

Application: abrasive belt, grinding wheel, sandblasting, paint or rust removal, refractory field.

Overseas friends from Turkey

Turkey friends from Ceramic Tile Company visit us for white fused alumina contract.

Keyword: white fused alumina

Regular Size: 16#, 40#, 100#, 120#, 180#, etc.

Application: abrasive belt, grinding wheel, polishing, etching, ceramic tiles, etc.

Overseas friends from South Africa

Africa friends came to our warehouse for silica sand inspection before shipment.

Keyword: silica sand for oil filteration

Regular Size: 0.5mm~325mesh

Application: construction, sandblasting, oil &gas, foundry, chemical, rubber, etc.

Ceramsite Sand for foundry

Sand Size ranges from 16~200mesh

Garnet Sand for waterjet Cutting

Garnet Size ranges from 16~120mesh

Hollow Glass Microshpere

Hollow Glass Microsphere for filler