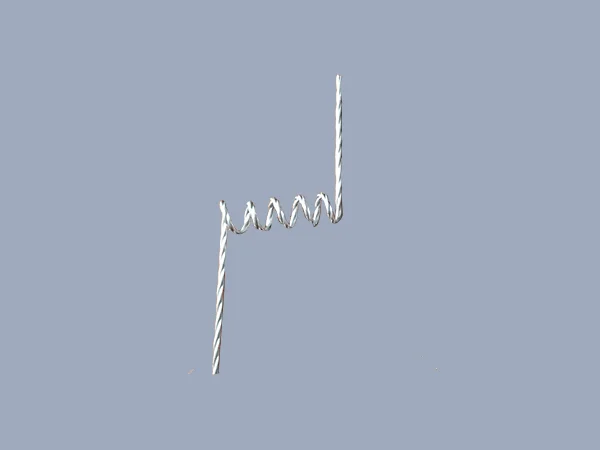

Скрученные нагревательные корзины из вольфрамовой проволоки для вакуумного покрытия Dia0.635mm 99.95% чистота

- Категория: Tungsten Wire >>>

- Поставщик: Luoyang,Robust,Tungsten&,Molybdenum,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-16-2025 | 0.33 $* | 0.14 $* |

| Aug-16-2025 | 0.30 $* | 0.32 $* |

| Jul-16-2025 | 0.89 $* | 0.23 $* |

| Jun-16-2025 | 0.31 $* | 0.49 $* |

| May-16-2025 | 0.26 $* | 0.58 $* |

| Apr-16-2025 | 0.97 $* | 0.96 $* |

| Mar-16-2025 | 0.99 $* | 0.25 $* |

| Feb-16-2025 | 0.51 $* | 0.84 $* |

| Jan-16-2025 | 0.14 $* | 0.62 $* |

Характеристики

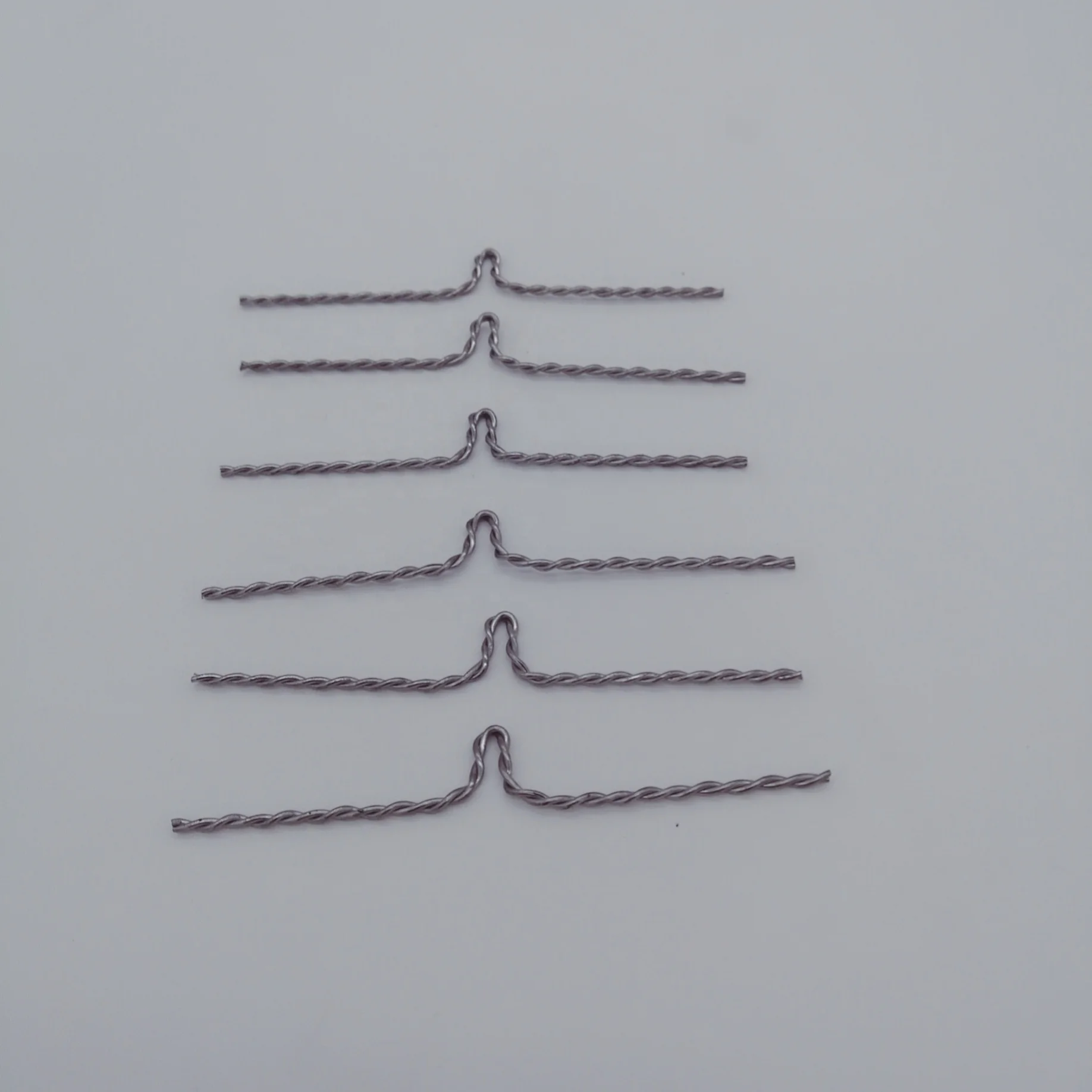

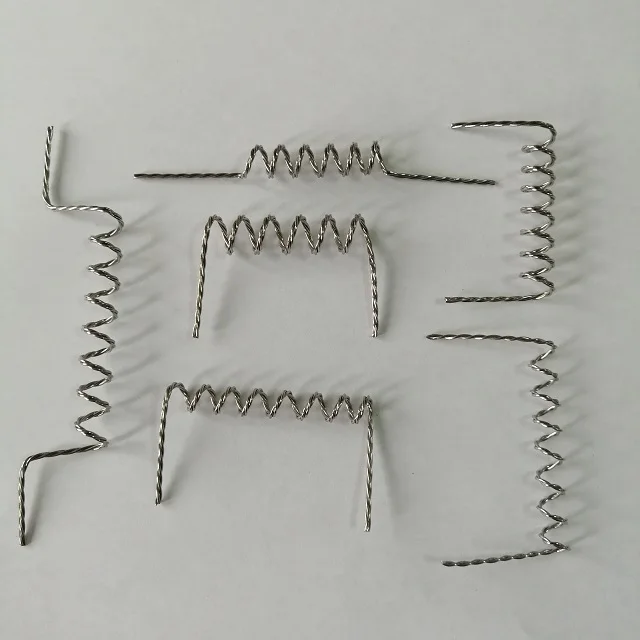

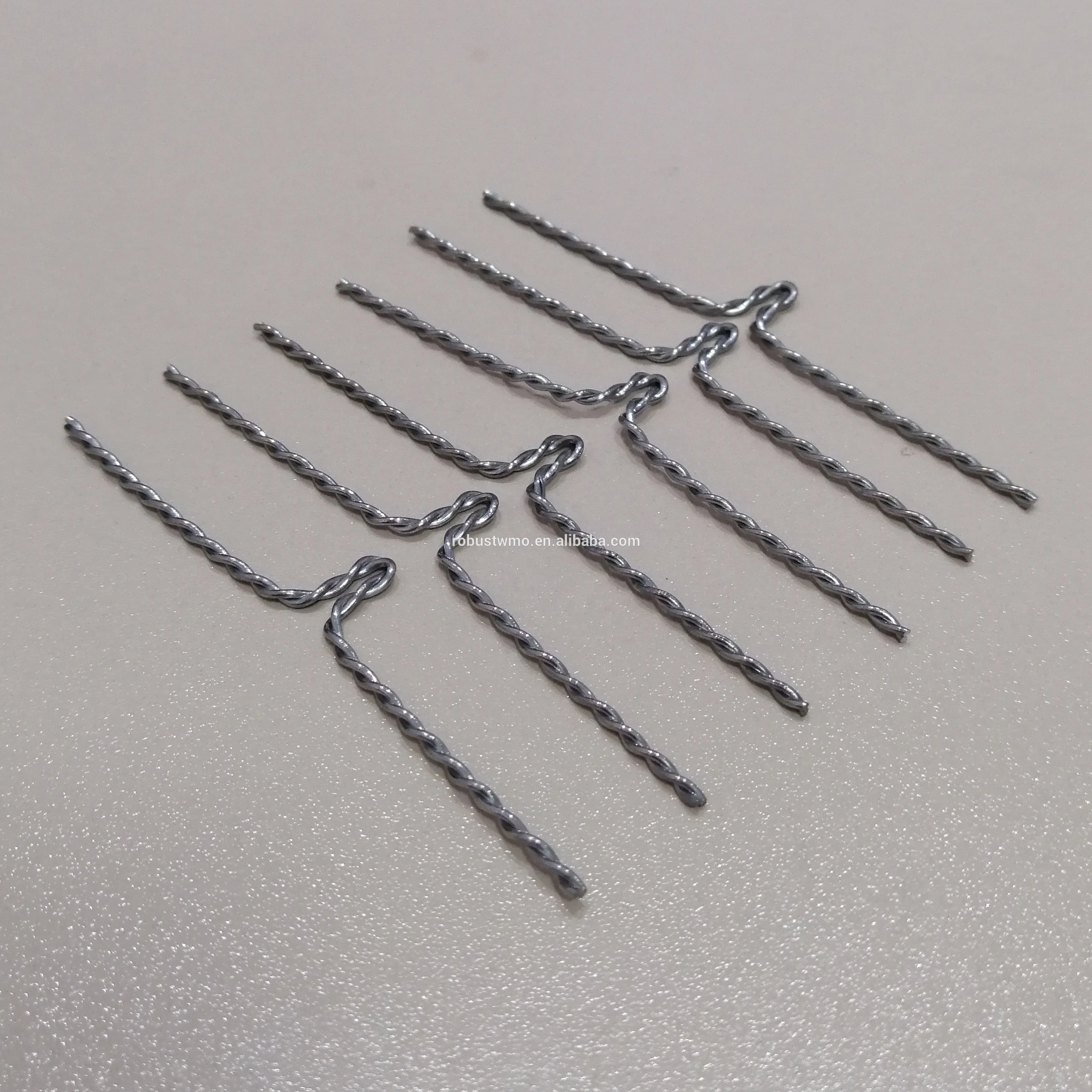

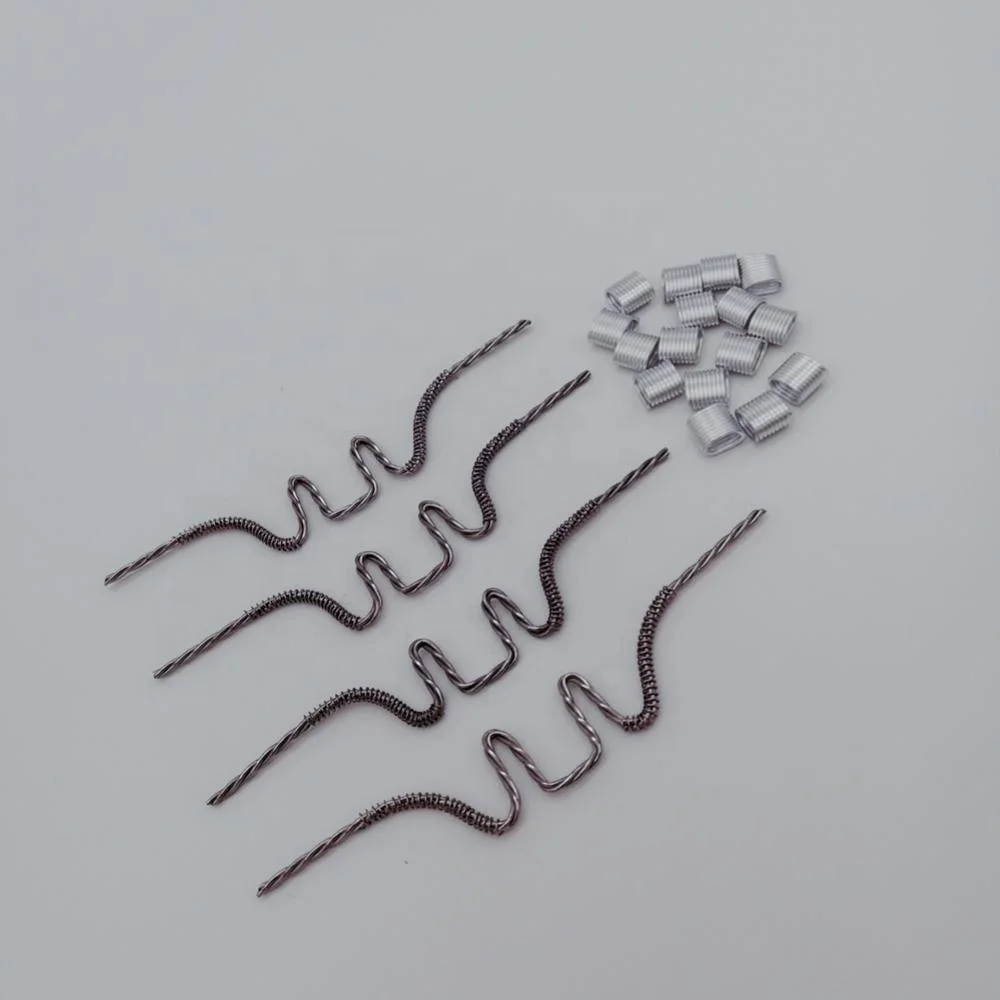

Product Name | dia0.635*45.72mm WAL1 twisted tungsten wire for vacuum coating with low price |

Diameter range | dia0.3-1.5mm |

Size | dia0.635*45.72mm, 3pcs twisted into 1pc |

Grade | WAL1 |

Surface | bright, polishing |

Main Features | high melting point, high resistance, good intensity and low evaporation pressure, long service life |

Application | Mainly applied for coating thin film in making christmas ball, bottle cap, shoe heel, reflection cap, lamp industry etc, as a heater in vacuum metalizing machine. |

ROBUST has very strict quality control policies in the whole process

ROBUST has a complete set of production lines and facilities

Honor & Testimonials

Packing Details : Vocuum Package, Wooden Case or as per customers' request

Delivery Details : Courier's Service, Air or Sea Transport or as per customers' request

US Customer Visit

Visit India

German Customer Visit

Q: Are you trading company or manufacturer ? what is vacuum metallizing? vacuum evaporation? vacuum desposition?

A: All of these terms can be used to describe the same process, with vacuum metallizing being a more specific case. Within the confines of a chamber which has had most of the air removed, metals or other materials are heated until they vaporize. This vapor travels about the chamber and condenses on surfaces within the chamber, forming a thin film.

Q: What materials are commonly vacuum coated?

A: Many metals, compounds, chemicals, and alloys can be evaporated and/or deposited. The material will dictate which of the

techniques listed above should be used. Please contact us for details on specific materials.

Q: What if I don’t see what I need on your website?

A: Ask us! Chances are that we can help, even if you don’t see the item on our site.

Q: When will I receive my quotation?

A: We understand the rapid pace of business these days. Our goal is to return a quotation to you within 24 hours of receiving your request. You can help speed this process by tolerancing prints, indicating purchase quantities, and specifying material compositions in your inquiry.