Wodon износостойкая проволока с сердечником из флюса для жесткого

- Категория: Welding & Soldering Supplies >>>

- Поставщик: Tianjin,Wodon,Wear,Resistant,Material,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Aug-19-2025 | 6.10 $* | 6.60 $* |

| Jul-19-2025 | 5.44 $* | 5.92 $* |

| Jun-19-2025 | 6.4 $* | 6.7 $* |

| May-19-2025 | 6.45 $* | 6.70 $* |

| Apr-19-2025 | 5.25 $* | 5.16 $* |

| Mar-19-2025 | 6.85 $* | 6.12 $* |

| Feb-19-2025 | 6.15 $* | 6.25 $* |

| Jan-19-2025 | 6.30 $* | 6.76 $* |

Характеристики

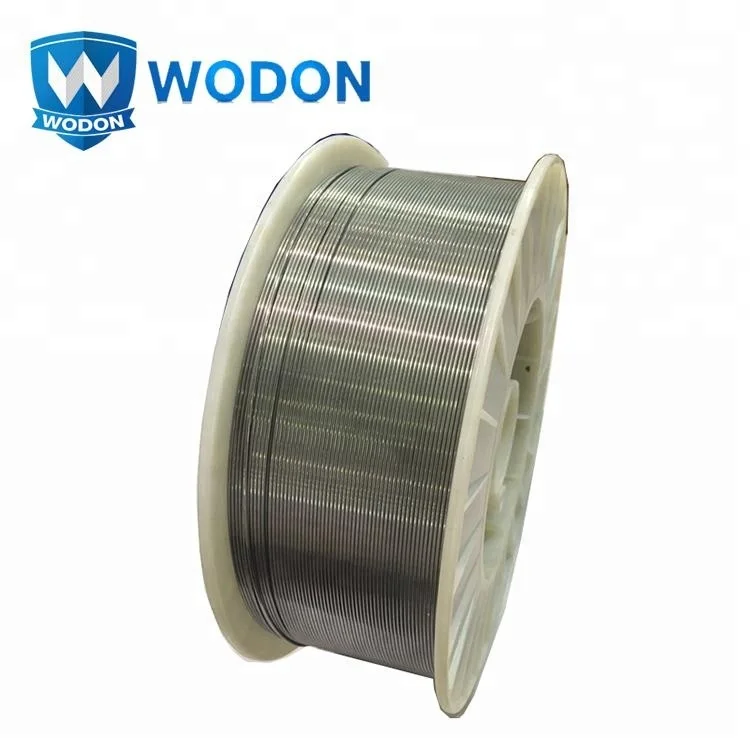

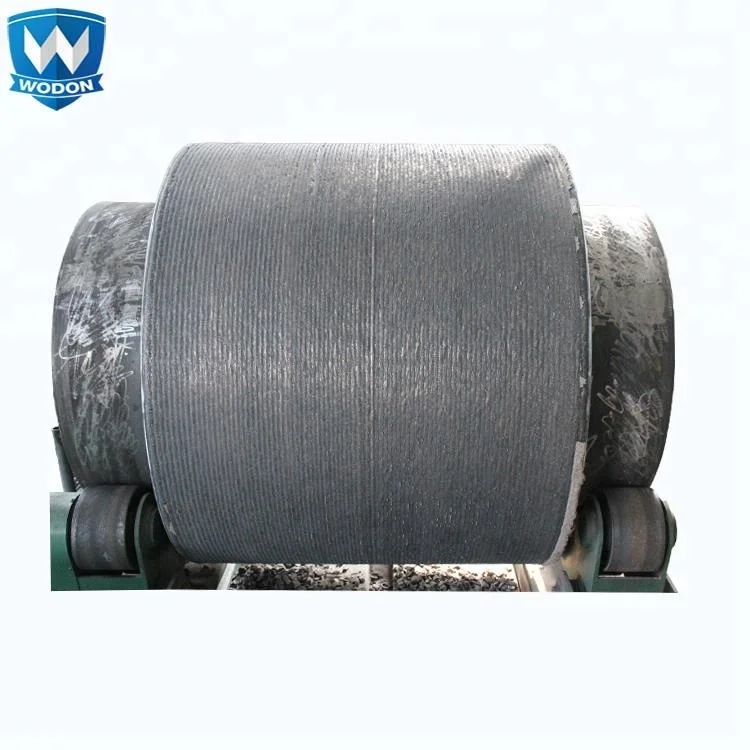

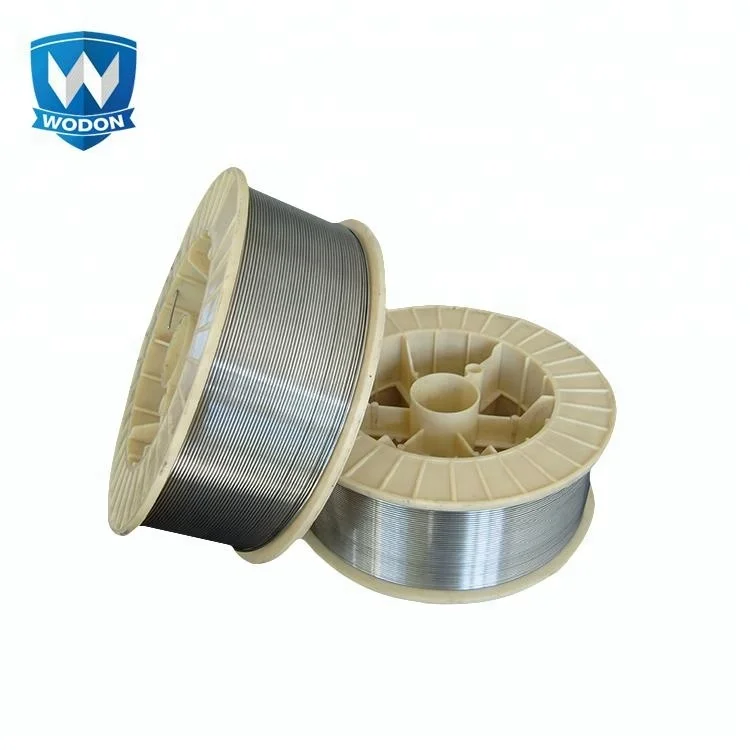

Wodon wear resistant flux core wire for hardfacing squeeze roller

abrasion wear resistant welding wire for squeeze roller repairing, hardfacing, reconditioned

Our company developed special Squeeze roller welding wires. We can guarantee high hardness and abrasion resistance after repairing, resulting in a service life no less than 8000 hours.

| Model | Spec. (mm) | Hardness (HRC) | Main Ingredient (%) | Application and Characteristics |

WD-ZYG100 (1#) | 1.6, 2.8, 4.0 | -- | C: 0.03~0.15 Mn: 0.5~2.5 | Used in squeeze roller backing welding |

WD-ZYG100 (1996) | -- | C: 0.05~0.15 Cr: 18~22 Ni: 8~11 Mn: 4~7 | Used in squeeze roller backing welding | |

| WD-ZYG200 | 20~35 | C: 3.5~4.6 Cr: 4.0~6.0 Mo: 0.3~1.0 Nb: 0.3~1.0 | Used for welding transition layer of extrusion roller | |

| WD-ZYG300 | 50~55 | C: 0.3~1 Cr: 5~10 Mo: 0.5~1.5 Nb: 1~3 | Used for welding transition layer of extrusion roller | |

| WD-ZYG500 | 1.6 | 55~60 | C: 0.5~2.5 Cr: 5~10 Mo: 0.5~1.5 Nb: 3~6 | Used in welding extrusion roller surface and pattern layer |

1. Chemical Composition: High carbon high chromium

2. Hardness: HRC58-65

3. Good Performance: no clearing slag, low welding spatter, smooth surface, high welding efficiency, stable filling rate, etc.

4. welding wire without any joints.

5. Production Capacity: 8000 tons per year

6. Short Delivery Time: Generally 7 days

7. We have many experienced professionals to research and develop welding wires according to customers' specified chemical compositions.

8. We can recommend proper welding wires and provide technical solutions based on working conditions.

9. on site inspection and third party inspection are available.

10. As an ISO9001:2008 approved manufacture, our mission is to improve our management system and provide high quality products continuously.

We are certified with the ISO9001:2008 and keep continuously improving our management quality system. We have strict procedures for raw materials and products inspection, production process, storage management and after sales service.

We are certified with the ISO9001:2008 and keep continuously improving our quality management system. We have strict procedures for raw materials, products inspection, production process, storage management and after sales service.

We are certified with the ISO1400:2004 and keep continuously improving our environmental management system. We use the electric boiler not the coal fired boiler to protect the environmental. We use the advanced dust removal and ventilation equipment to keep the air clean.

We are certified with the OHSAS18001-2007 and keep continuously improving our occupational health and safety management system. Our every technical staff wears filter mask, protective clothing and gloves and welding goggles.

Tianjin Wodon Wear Resistant Material Co., Ltd is located in Tianjin city, China's northern international shipping center. We are specialized in researching, developing and producing wear resistant products with many years experience in this field. We have more than 200 employees, with an annual output of 90000 squaremeters of wear plates and 9000 tons of welding consumables.

Our company covers the area about 43000 square meters. And this year we are established one more branch factory in Tianjin to improve our production capacity.The new branch factory will be finish and full function operate in June 2017 according the company's policy.

There are 3 Workshops (36000 square meter) only in Tianjin now, after the new branch factory finished, we will have one more big Workshop in Tianjin, so that have more place to process wear resistant work pieces like wear resistant liner, pipe and fittings and wear resistant steel plates.

With solid technical knowledge and R&D capacity, we have many experienced surface engineering professionals and often invite experts as advisers to provide solutions related to industrial abrasion. Our products have been widely applied in different in dustries like: power, cement, iron and steel, mining, port, coal, petroleum, chemical industry, railway, valves, sugar and shipbuilding industry. In addition, our company can offer professional solutions for the abrasion in different working conditions in order to reduce costs, increase lifetime of the workpiece and extand equipment overhaul period, therefore building a very good reputation among our customers.

Our flux cored welding wire with 1.6 mm are vaccum packed without a joint and put into cartoon easy to transport. The goods have above one year quality guarantee period. If the goods keep in a dry environment, they may have much longer quality guarantte period.

We have our own Quality Inspection Technology Department and the team are made of many experience exports with material science bachelor-degree and the leaders with material science master-degree. In the pictures you can also see our equipment in our laboratory. Our inspection team make regular testing on raw material, production process and our products according our company's strict policy.

The above picture shows our laboratory. There are many equipments to suppert our Quality Inspection Technology Department, for sample: a series of metallographic analysis equipments, protable spectrum, protable ultrasonic thickness tester, protable ultrasonic hardness tester, destop Rockwell hardness tester, Infrared carbon sulfur analyzer, Quartz sand rubber wheel abrasion test machine and Reciprocating abrasion tester.

Packaging: 15 kg/Spool, 50 kg/spool, 150-250 kg/drum without joint, Steel Pallet, Plastic film, Customized

Packing Size: 1.15m*0.58m*0.88m, 1.15m*1.15m*0.88m, customized

Delivery Detail: Generally 7 days if the goods are in the store, or it is 10~15 Days.

Loading into the 20 ft or 40 ft Container.

Our flux cored welding wire with 1.2&1.6 mm are vacuum packed into cartoon, the anderes are waterpoof packing with desiccant. They all have long quality garantee period above 1 year, if the goods keep in the dry environment. The steel pallet surppert our goods safety and easy to transport.

Our company has a professional after-sales service team, with many years of experience not ony on hardfacing products and applications, but also on the opertion of application equipemt. We are able to quickly solve customer's problems. If there are any quality problems, the responsible person will provide reasonable solutions within 12 hours after being notified.

Q: Are you trading company or manufacturer ?

A: We are manufacturer with more than 3 factorys, our own sales department and our own inspection technology department.

Q: How long is your delivery time?

A: Generally it is 5-10 days if the goods are in stock. or it is 15-20 days if the goods are not in stock, it is according to quantity.

Q: Do you provide samples ? is it free or extra ?

A: Yes, we could offer the sample for free charge.

Q: What is your terms of payment ?

A:30% T/T in advance ,balance against copy of BL.

also, FOB, CIF, CFR all are available for your product.

If you have another question, pls feel free to contact us as below: