5083 прокатная кольцевая ковка для ветровой

- Категория: Ковка >>>

- Поставщик: Chongqing,Huanyu,Aluminum,Material,Co.,Ltd.,[Chongqing,China]Chongqing

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-16-2025 | 884403.8 $* | 928623.50 $* |

| Aug-16-2025 | 876971.17 $* | 920820.32 $* |

| Jul-16-2025 | 735764.15 $* | 772552.33 $* |

| Jun-16-2025 | 862107.31 $* | 905212.28 $* |

| May-16-2025 | 750628.46 $* | 788159.22 $* |

| Apr-16-2025 | 847243.40 $* | 889605.80 $* |

| Mar-16-2025 | 839811.86 $* | 881802.27 $* |

| Feb-16-2025 | 832380.97 $* | 873999.54 $* |

| Jan-16-2025 | 824948.50 $* | 866195.19 $* |

Характеристики

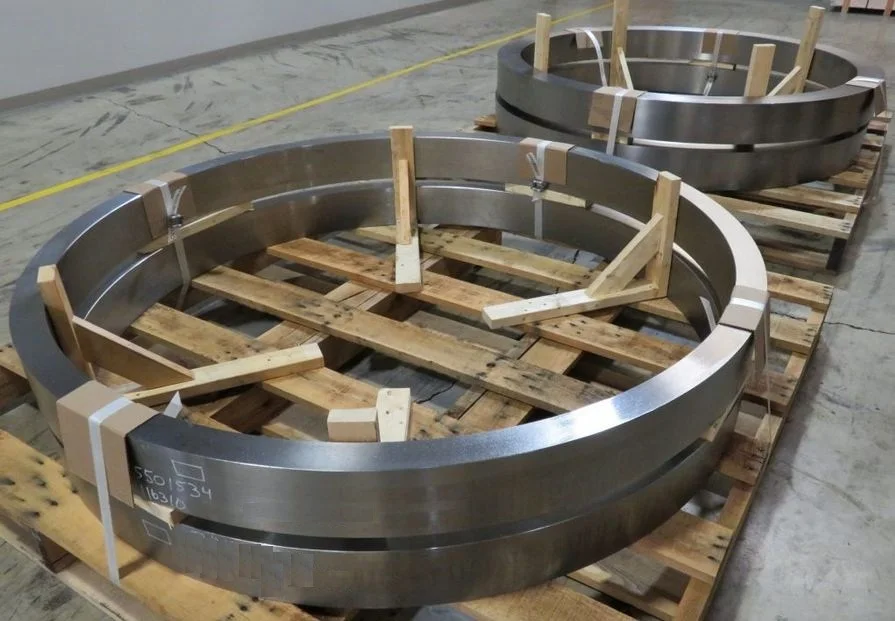

rolled ring forging for wind turbine

rolled ring forging for wind turbine

RING FORGING Rolled Ring Forging

Seamless forged rings can be produced by a process called ring rolling. Ring roll production begins with a circular preform of metal that has been pierced (using the open die forging process) to form a “ring blocker”. This blocker is then reheated to the proper temperature for that grade of material and placed over a mandrel. The mandrel then moves to a drive roll (king roll) that rotates under pressure to reduce the wall thickness, thereby increasing the diameters (I.D. and O.D.) of the ring forging.

Depending on the size, seamless rings can also be produced by simple piercing of a forging, either open die or with the outside diameter contained in a tool. Other manufacturing methods such as mandrel rolling under a hammer or press or drawing the material over a mandrel bar. We uses all of these methods to produce seamless forged rings of the highest quality and integrity.

| MATERIAL | aluminum alloy 7072T6 |

| Tolerance | ±0.01mm |

| Extent | 0.5mm~1020mm |

| CNC turning work range | φ0.5mm~φ300mm × 650mm |

| CNC milling work range | 1500mm × 800mm ×500mm |

| SURFACE TREATMENT | powder coating, aluminum oxide |

| APPLICATION | new energy vehicles, aerospace, automation equipment, etc. |

| COMPETIVE ADVANTAGE | 1.Small order acceptable. |

| 2.Very tight tolerance. | |

| 3.Advanced equipment, excellent R&D teams. | |

| 4.Strict quality control system. | |

| 5.Professional technics and rich experience. | |

| 6.Packaging details as clients required. | |

| INFORMATION TO INQUIRY | 1.Type of material and hardness needed. |

| 2.Quantity of the product. | |

| 3.Part application. | |

| 4.The tolerances of the product. | |

| 5.Drawings, samples or pictures with details. | |

| 6.Target price if you have one. |

| Packaging | As per customer's request |

| Inspection | 100% Inspected Before Delivery |

| Technology Documents: | 2D Drawing or 3D Drawing |

| Processing: | CNC Machining sheetmetal |

Company Name: | Chongqing Huangyu Aluminum Material Co., Ltd. |

Mail Sites:

| http://en.hy-al.cn |

http://www.hy-al.cn | |

Emal Add.:

| Oliver (at) hy-al.cn |

hy (at) hy-al.cn | |

huanyu.aluminum (at) yahoo.com | |

Cellular Phone Number | +86(0)136-8240-5276 |

Phone Number: | +86-23-65819199 / +86-23-65820299 |

Skype online: | cy2005oliver |

QQ online : | 630348062 |

WhatsApp: | +86(0)136-8240-5276 |

Founded year: | 1994 |

Professional Technicians: | 11 |

Annual Turnover: | US$5.0M-12.0M |

Product Range: | Aluminum Forgings Aluminum Forgings |

Aluminum Rods Aluminum Rods | |

Aluminum Bars Aluminum Bars | |

Aluminum Tubes & Pipes Aluminum Tubes & Pipes | |

Aluminum Plate&Sheets Aluminum Plate&Sheets | |

Aluminum Profiles Aluminum Profiles | |

OEM projects: | Acceptable |

Customized Logo: | Acceptable |

Похожие товары

Данные ресурс не является интернет-магазином, а лишь содержит ссылки на международную торговую площадку Alibaba.com