Криогенный генератор кислорода азота для разделения

- Категория: >>>

- Поставщик: Hangzhou,Kelin,Aier,Qiyuan,Equipment,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Aug-17-2025 | 95678.40 $* | 97592.67 $* |

| Jul-17-2025 | 77597.75 $* | 79149.63 $* |

| Jun-17-2025 | 94171.89 $* | 96054.36 $* |

| May-17-2025 | 93418.26 $* | 95286.87 $* |

| Apr-17-2025 | 74584.52 $* | 76076.66 $* |

| Mar-17-2025 | 91911.74 $* | 93749.23 $* |

| Feb-17-2025 | 91158.90 $* | 92981.23 $* |

| Jan-17-2025 | 90404.54 $* | 92212.43 $* |

Характеристики

Cryogenic Air Separation Oxygen Nitrogen Generator Plant

Purity:99.5%~99.9995% high purity oxygen plant

Features:

* Low investment, small workload of construction;

* Low energy consumption, advanced process system;

* High automation, less operators;

* Quickly start, and conveniencely open and shut down;

* Low costs of maintenance;

* Stable operation and highly reliable;

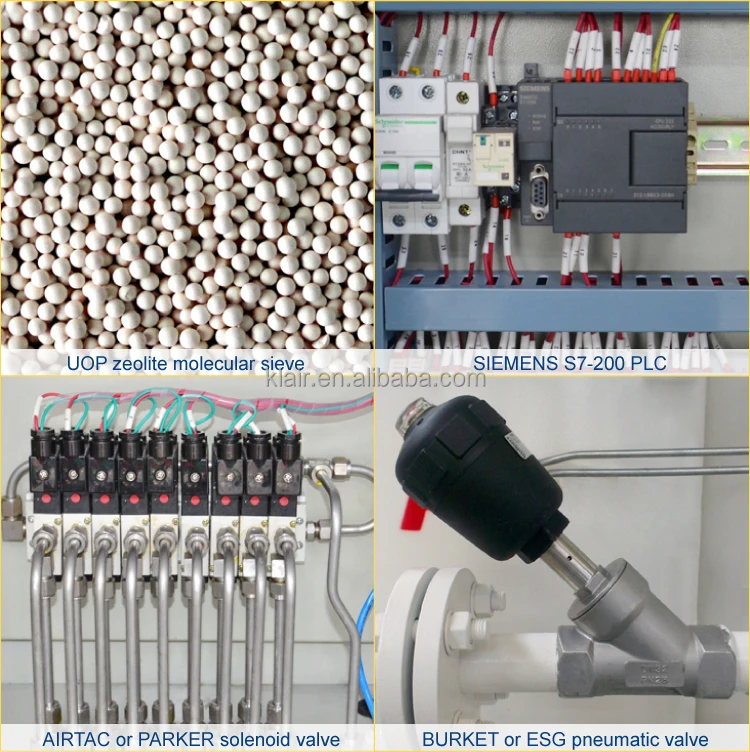

* High quality pneumatic control valves, safe, reliable and durable;

* High quality special oxygen molecular sieve adsobent, good adsorption properties.

How it works ?

The raw air will be removed its particle by inlet filter and then be pressurized to about 40Kpa.

The air temperature from the air blower is about 75C, after to be cooled by cooling water, it will flows into one of adsorption tower which filled with adsorber.When the raw air flows from the bottom tower to upper tower, the

nitrogen will be adsorbed, oxygen will be oncentrated at the top of tower and be delivered out as product gas.

When the adsorber almost reaches to saturation, in the action of controller, the valves will be switched, the rawair flows into annotheradsorption tower to adsorb. Saturated adsorption tower will be decompressurized to atmosphere pressure andthen be vacuumized to about -60Kpa,product gas will be introduced into the tower to pruge the adsorption bed, thereby,the adsorber will bedesorbed, and prepare for the next cycle.

The two adsorption towers adsorb and desorb alternately to produce oxygen gas continuously.Raw air shifting from one adsorption tower to another tower is controlled by pneumatic valves, the action process of valves is realized by PLC controller. Centralized control system enables the whole system to work automatically.

Flow Chart:

1.Air compressor one set

2.Compressed air pretreatment system (dryer and multistage filters) one set

3.Air buffer tank one set

4.PSA oxygen generator one set

5.Oxygen gas buffer tank one set

6.Oxygen booster one set

7.Filling station one set

8.Control system one set (including man-machine control interface)

9.Instrument and meter (installed in nitrogen generator) one set

Specifications

| Model | Capacity(Nm3/h) | Air consumption(Nm3/min) | Purity (%) | Outlet pressure (bar) | Buffer tank |

| KPO-5 | 5 | 1.2 | 93% | 2~3 | CG-0.3 |

| KPO-10 | 10 | 2.5 | CG-0.5 | ||

| KPO-15 | 15 | 3.5 | CG-0.6 | ||

| KPO-20 | 20 | 5.0 | CG-1 | ||

| KPO-30 | 30 | 7.5 | CG-1.5 | ||

| KPO-35 | 35 | 8.5 | CG-2 | ||

| KPO-40 | 40 | 10.0 | CG-2 | ||

| KPO-50 | 50 | 12.0 | CG-2.5 | ||

| KPO-60 | 60 | 15.0 | CG-2.5 | ||

| KPO-80 | 80 | 19.0 | CG-2.5 | ||

| KPO-100 | 100 | 24.0 | CG-4 |

Related Products:

1. Are you manufacturer or Trade Company?

We are OEM professional air dryer, founded in 1997.

Leading products: compressed air dryer, desiccant air dryer, air filter, water chiller, PSA gas generator.

2. What terms of payment you use?

T/T, L/C

3. Do you have any instant chat tool?

Any Inquiry or question, pls contact:

Lxsue Zhu

Hangzhou Kelin Aier Qiyuan Equipment Co.ltd

Main Product: air dryer & water chiller & gas generator etc.

Add:Anxi Industrial Zone,Liangzhu,Yuhang,Hangzhou,China

Tel :+86-571-88791018

Fax:+86-571-88792222

Mobile:+86-18557518317

Email:lxsue(at)klqy.com

Website:www.klqy.com

4.Please filling the following basic data for us prompt reply

1. Gas type: nitrogen gas or oxygen generator

2. Application:

3. Flow capacity: XXNm3/h or how many 40L cylinders per day.

4. Gas pure:

5. Voltage:

6. Need booster & filling ramp or not:

7. Sea level:

8. Other requirement:

Welcome to>>

Hangzhou Kelin Aier Qiyuan Equipment Co., Ltd.

Похожие товары

Данные ресурс не является интернет-магазином, а лишь содержит ссылки на международную торговую площадку Alibaba.com