Inox шара 200 мм 250 зеркало хром глядя нержавеющая сталь DY-STEEL мяч 300 серии листы нержавеющей стали холодного проката Aisi astm сварки CN;GUA спортивные

- Категория: Шары из нержавеющей стали >>>

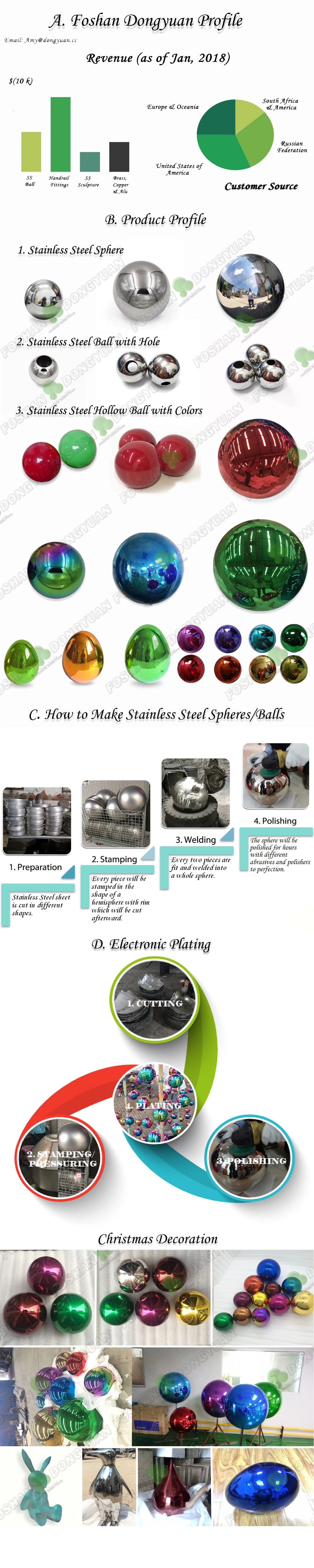

- Поставщик: Foshan,Dongyuan,Limited

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-19-2025 | 0.98 $* | 0.52 $* |

| Aug-19-2025 | 0.53 $* | 0.91 $* |

| Jul-19-2025 | 0.15 $* | 0.34 $* |

| Jun-19-2025 | 0.88 $* | 0.87 $* |

| May-19-2025 | 0.98 $* | 0.26 $* |

| Apr-19-2025 | 0.66 $* | 0.47 $* |

| Mar-19-2025 | 0.25 $* | 0.78 $* |

| Feb-19-2025 | 0.64 $* | 0.52 $* |

| Jan-19-2025 | 0.33 $* | 0.67 $* |

Характеристики

200mm, 250mm, Mirror Chrome Gazing Stainless Steel Inox Sphere Ball

SPECIFICATION | ITEM NAME: 200mm, 250mm, Mirror Chrome Gazing Stainless Steel Inox Sphere Ball |

SIZE: 200mm, 250mm | |

THICKNESS: 0.6mm-1.5mm | |

FINISH: Mirror Polished, Brushed/Matt, Sandblasted, Painted and Plated etc. | |

MATERIAL: Heavy Duty Type AISI304 | |

Applied Technology: Cutting, Stamping, Polishing & Brushing | |

Tools: welding guns and polishing machines | |

Package: Customized wooden case, EPE and cushion on the bottom (depending on means of transport). | |

Use:

Feature:

|

We are capable of providing stainless steel spheres/balls almost as per your specific requirements. Products include hollow stainless steel spheres (ranging from 6mm to 2500mm in diameter), available for delivery if we have it in stock or delivered within 15 days. Wall thickness of spheres varies from 0.4mm to 3mm. Shaped by water pressure, our products could be mirror polished without any seams noticeable on the surface; meanwhile, welding and then sandblasting spheres is a another way to produce mirror polished spheres also without detectable traces on the spheres. Having been offering services for our customers worldwide, a variety of products also fall under many categories of our products. Staidness steel spheres, hollow or solid, of all sizes are our major products, and brass and bronze balls come along. Hollow reflective stainless steel spheres of enormous sizes are amongst the top sales in our products. Perforated stainless steel spheres or sculptures of 304 or 316 are also our hot products. Not to mention we have done considerable amount of drilled stainless steel balls or spheres with holes of many sizes. Our products are of professional and advanced technology with cost-effective craftsmanship and favorable delivery time.

Austenitic:

Austenitic steels have austenite as their primary phase (face centered cubic crystal). These are alloys containing chromium and nickel (sometimes manganese and nitrogen), structured around the Type 302 composition of iron, 18% chromium, and 8% nickel. Austenitic steels are not hardenable by heat treatment. The most familiar stainless steel is probably Type 304, sometimes called T304 or simply 304. Type 304 surgical stainless steel is an austenitic steel containing 18-20% chromium and 8-10% nickel.

Ferritic:

Ferritic steels have ferrite (body centered cubic crystal) as their main phase. These steels contain iron and chromium, based on the Type 430 composition of 17% chromium. Ferritic steel is less ductile than austenitic steel and is not hardenable by heat treatment.

Martensitic:

The characteristic orthorhombic martensite microstructure was first observed by German microscopist Adolf Martens around 1890. Martensitic steels are low carbon steels built around the Type 410 composition of iron, 12% chromium, and 0.12% carbon. They may be tempered and hardened. Martensite gives steel great hardness, but it also reduces its toughness and makes it brittle, so few steels are fully hardened.

There are also other grades of stainless steels, such as precipitation-hardened, duplex, and cast stainless steels. Stainless steel can be produced in a variety of finishes and textures and can be tinted over a broad spectrum of colors.

Chrome Steel Ball

Chemical Composition

| C% | Si% | Mn% | Cr% | Cu% | S% | P% |

| 0.90~1.05 | 0.15~0.35 | 0.25~0.45 | 1.35~1.65 | 0.3max | 0.03 max | 0.03max |

Density: 7.84 g/cm3

Hardness: through hardened, HRC 60 Min

Grade: 5~grinding grade

Size: 0.5mm~2"

| Fabrication Properties | |

| Joining Technique | Suitability |

| Soldering | Excellent |

| Brazing | Excellent |

| Oxyacetylene Welding | Good |

| Gas Shielded Arc Welding | Good |

| Coated Metal Arc Welding | Not Recommended |

| Spot Weld | Fair |

| Seam Weld | Not Recommended |

| Butt Weld | Good |

| Capacity for Being Cold Worked | Excellent |

| Capacity for Being Hot Formed | Fair |

| Machinability Rating | 30 |

Because this material has 1% carbon, it does not weld well. It can be resistance welded with difficulty. It can be soft soldered with a high tin solder using an acid flux. It can be silver soldered or brazed; but the heat will cause distortion of the ball and a loss of hardness. For light load applications, the ball can be attached with an adhesive such as epoxy. When adhesive bounding is used, an area on the ball should be roughed up by etching or abrasive blasting. The area should be thoroughly cleaned.

Chrome steel balls will rust if they are in contact with water. Consider using stainless steel balls or brass balls in a wet environment.

All of the above are common ways of describing the most widely used material for the manufacturer of precision steel balls. It is a through hardening, fine grain, Martensitic steel. Because of its high hardness and fine grain structure, this material can be finished to an extremely fine quality.

1. Fast delivery for samples

2. Free sample and inexpensive cost for delivery to your door