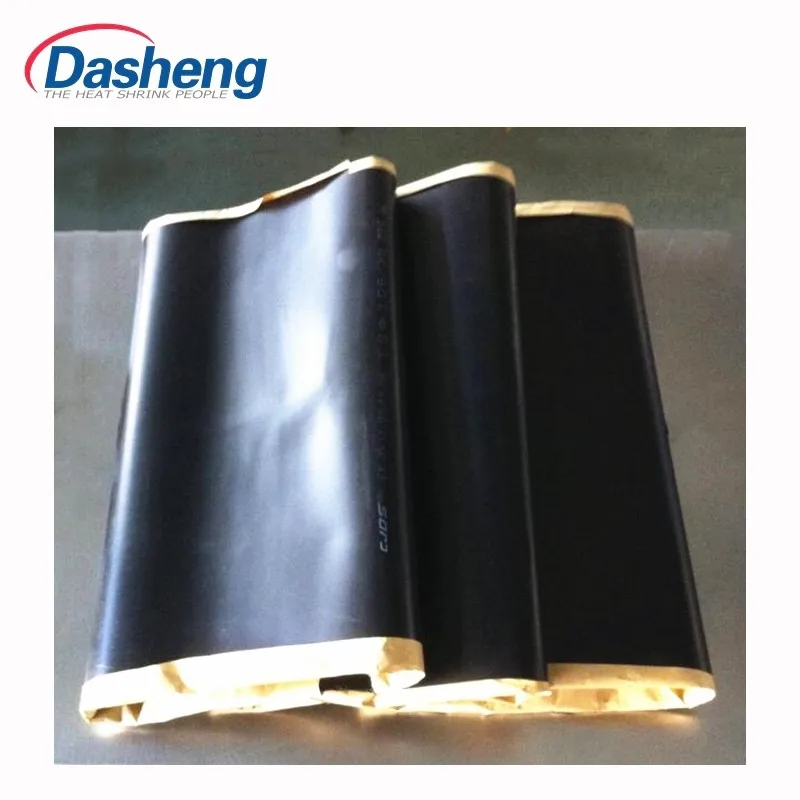

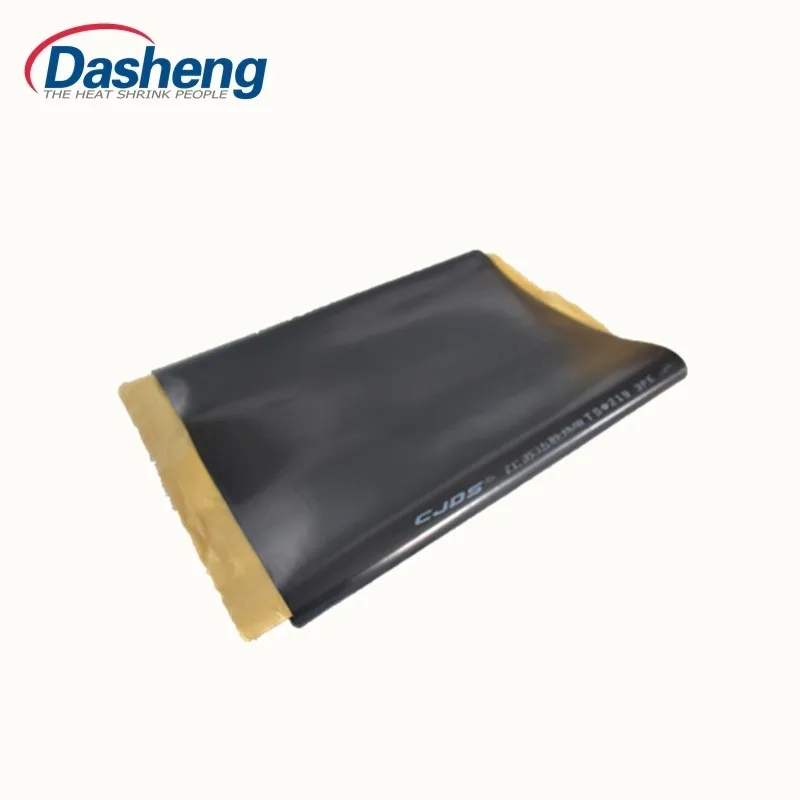

Обвивающиеся вокруг ноги термоусадочный рукав (с закрытием патч) анти-коррозия термоусадочная трубка для бурения нефтяных и газовых

- Категория: >>>

- Поставщик: Suzhou,Dasheng,Heat,Shrinkable,Material,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Aug-16-2025 | 6.92 $* | 6.0 $* |

| Jul-16-2025 | 5.35 $* | 5.37 $* |

| Jun-16-2025 | 6.67 $* | 6.99 $* |

| May-16-2025 | 6.7 $* | 6.27 $* |

| Apr-16-2025 | 5.80 $* | 5.38 $* |

| Mar-16-2025 | 6.61 $* | 6.60 $* |

| Feb-16-2025 | 6.51 $* | 6.4 $* |

| Jan-16-2025 | 6.54 $* | 6.55 $* |

Характеристики

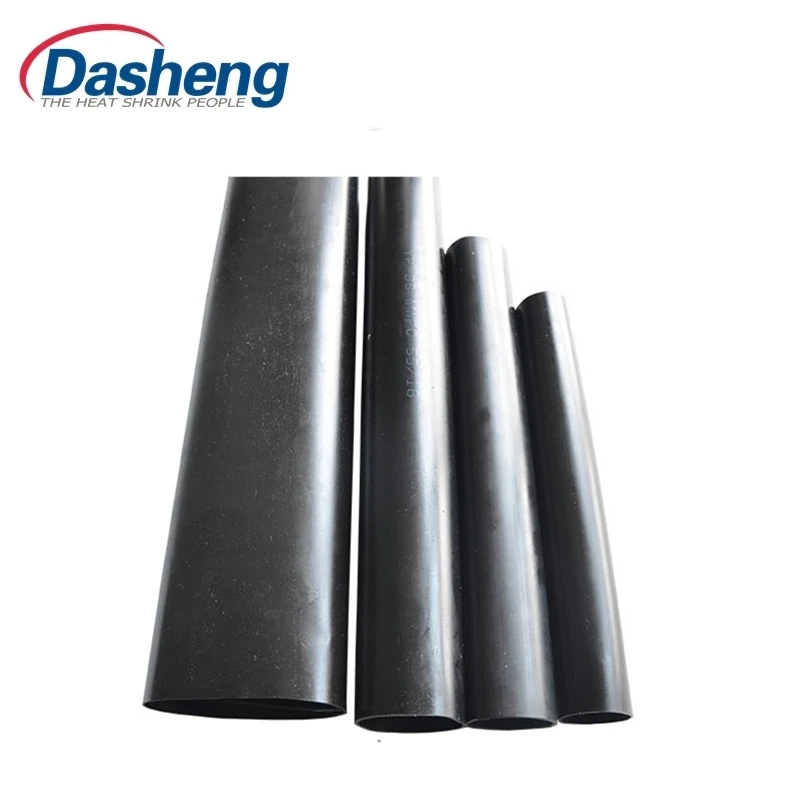

TS60 Oil and gas pipeline heat shrink sleeve

TS60 tubular sleeve is designed for corrosion protection of girth weld joint of buried and exposed steel pipes, especially for 3-layer coated oil and gas pipeline.

Construction: 3-layer system

First layer: Liquid epoxy primer, solvent-free two-component.

Second layer: High shear strength hot-melt copolymer adhesive.

Third layer: Radiation cross-linked, high density polyethylene backing.

Installation:

During installation, the epoxy primer is applied to the prepared pipe surface and the heat shrink sleeve is immediately set around the joint over the wet epoxy. Heat is then applied to the sleeve which shrinks to form a tight fit around the joint. While curing, the epoxy forms strong mechanical and chemical bonds to the pipe surface & to the copolymer adhesive layer. The radiation cross-linked outer layer forms a tough barrier against mechanical damage and moisture transmission.

Property | Test Method | Unit | TS60 (2PE) | TS60 (3PE) |

Tensile Strength | ASTM D638 | psi | 2700 | 2700 |

Ultimate Elongation | ASTM D638 | % | 650 | 650 |

Volume Resistivity | ASTM D257 | Ω-cm | 1x1016 | 1x1016 |

Dielectric Strength | ASTM D149 | kV/mm | 20 | 20 |

Water Absorption | ASTM D570 | % Wt | 0.05 | 0.05 |

Softening Point | ASTM E28 | ºC | 90 | 103 |

Peel Strength | DIN EN12068 | N/cm² | 60 | 70 |

Lap Shear Strength | DIN EN12068 | N/cm² | 140 | 300 |

Impact Resistance | DIN EN12068 | J | >15 | >15 |

Penetration Resistance | ASTM G17 | - | Pass | Pass |

Cathodic Disbondment | DIN EN 12068 | mm-radius | <15mm | <15mm |