Факел самостоятельно TB780D б/у волной припоя машина с высоким

- Категория: Electronic Products Machinery >>>

- Поставщик: Beijing,Torch,SMT,Incorporated,Company

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-16-2025 | 0.92 $* | 0.61 $* |

| Aug-16-2025 | 0.74 $* | 0.97 $* |

| Jul-16-2025 | 0.56 $* | 0.46 $* |

| Jun-16-2025 | 0.77 $* | 0.51 $* |

| May-16-2025 | 0.60 $* | 0.7 $* |

| Apr-16-2025 | 0.76 $* | 0.21 $* |

| Mar-16-2025 | 0.61 $* | 0.90 $* |

| Feb-16-2025 | 0.40 $* | 0.67 $* |

| Jan-16-2025 | 0.92 $* | 0.27 $* |

Характеристики

TORCH independently TB780D used wave solder machine with high quality![TORCH lead free wave solder machine TB780D Automatic soldering machine]()

Specifications

advantages

1. low energy consuming,

2. quickly tin melting, easy to operate

3. simple to repair as well as maintaince

Features and function:

Flux spray system

A function of flux spray device

1 nozzle: import nozzle, better spray

2 air system: AIRTAC electromagnetism valve, anti-corrosive pipe

3 moving nozzle system: air cylinder driven, spray speed and spray width can be adjusted by handle.

4 filtration flux system: collecting device is made of multi collecting lay, it is convenient to clean.

5 flux controlling: anti-corrosive controlling flux and display flux.

B function of flux foam device

With foam function, inner foam pump, it don’t need outer air supply, it is convenient to spray flux.

1 preheating temperature range: room temperature—260°C

2 controlling way: with PID controlling to make welding process.

3 Heat: infrared heating, temperature uniformity, rapid speed, PID supply heat.

4 Preheating security: surface temperature is lower than fire point of flux.

5 Preheat: it can meet preheating need of batch PCB welding, uniformity temperature, small temperature differences of PCB.

Welding system features:

1 Material: 316 stainless steel

2 Capacity: 100kg double wave crest capacity

3 Height range of wave crest: 0—8mm adjustment and keep wave crest balance.

4 Power consumption (heater): 6kw, uniformity heat, long life. It will take 1 hour to melt tin. This can save 6kw during melting tin and save 3kw during constant temperature.

5 Unique nozzle: double wave crest design, with unique flat wave which is stable and reduce SMD leaking solder.

6 Heat controlling system: PID control, accuracy is ±2

7 Moving tin pot: in and out can be finished by hand.

8 Motor of wave crest: import motor, running stable.

9 Tin pipe: screw thread stem

import motor

The position of tin pot and wave hole

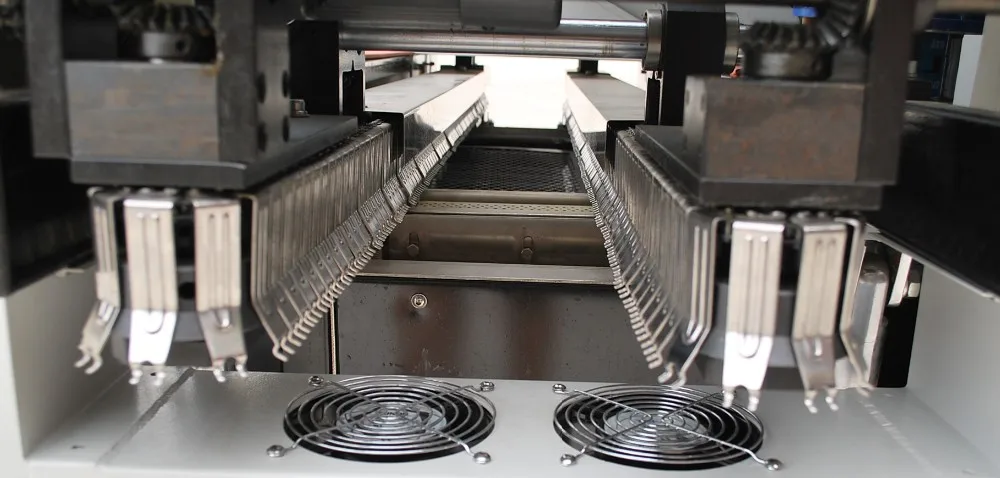

Cooling system

1 Cooling motor: unique cooling design, it can achieve import device effect.

Transmission system

1 chain: stainless steel chain, anti-corrosive, ametabolic.

2 rail system: special strong aluminum

3 speed: 0—1800mm/min

4 accuracy: motor is from Taiwan, it is easy to adjust and maintain.

Controlling system

1 buttons on the panel: manual/ automatic control, speed can be set, temperature can be display.

2 protect short circuit: with short circuit protection, with Sanling air switch protection in main power and tin pot of preheating zone, with fuse power in controlling system.

3 urgent stop protection: there are 2 urgent stop protection in the machine, please cut off power in urgent condition.

4 whole machine controlling: relay controlling.

5 transmission speed: Taiwan motor makes sure stable speed.

6 wave crest: Taida transducer makes wave crest flatter.

7 over-current protection: over-current protection with transducer, it will cut off power when current is over to make motor safe.

8 modularization wiring device: there are main wiring modularization and controlling modularization.

Technology parameters:

Specification | TB780D(double wave crest) | |

1 | solder type | lead / common solder |

2 | max PCB | 50—200mm |

3 | Components height | Above ≤130mm under ≤8mm |

4 | Capacity | 100KG |

5 | Preheating length | 600mm |

6 | temperature accuracy | ±2 |

7 | spray way | Foam |

8 | temperature range | room - 300 |

9 | wave height | 0—8mm, keep balance wave crest |

10 | heating controlling | PID |

11 | speed | 0—1800mm/min |

12 | start power/normal power | 12KW/6KW |

13 | preheating temperature | room—260°C |

15 | Width adjust | Manual adjusting |

16 | Transmit angle | 3-8 |

17 | Direction | right→left |

18 | controlling accuracy | Taiwan motor |

19 | Weight (Kg) | 650KG |

20 | Dimension L x W x H(mm) | 1400*1000*1500MM |