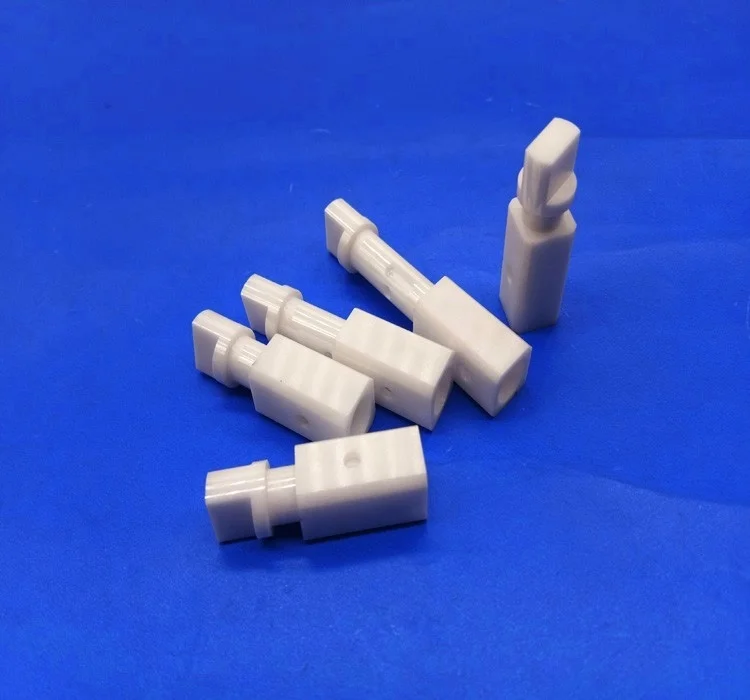

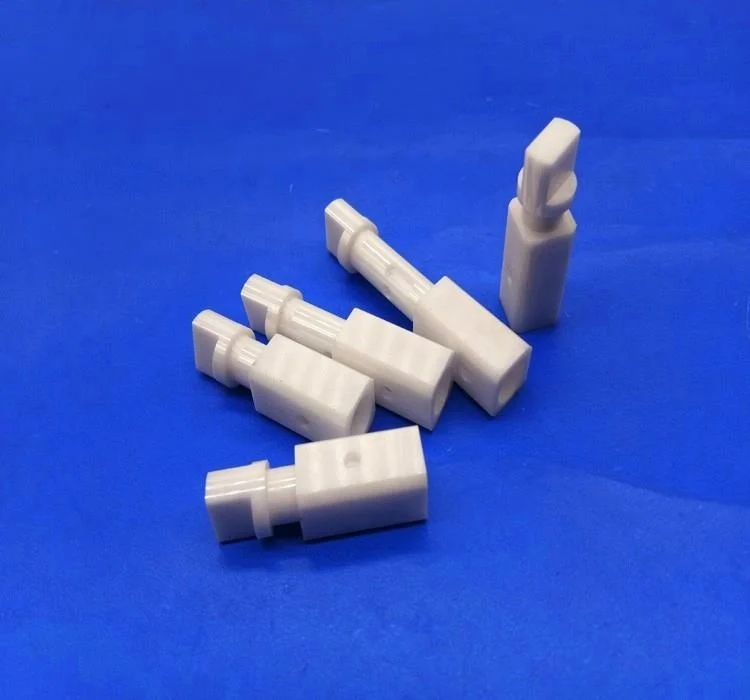

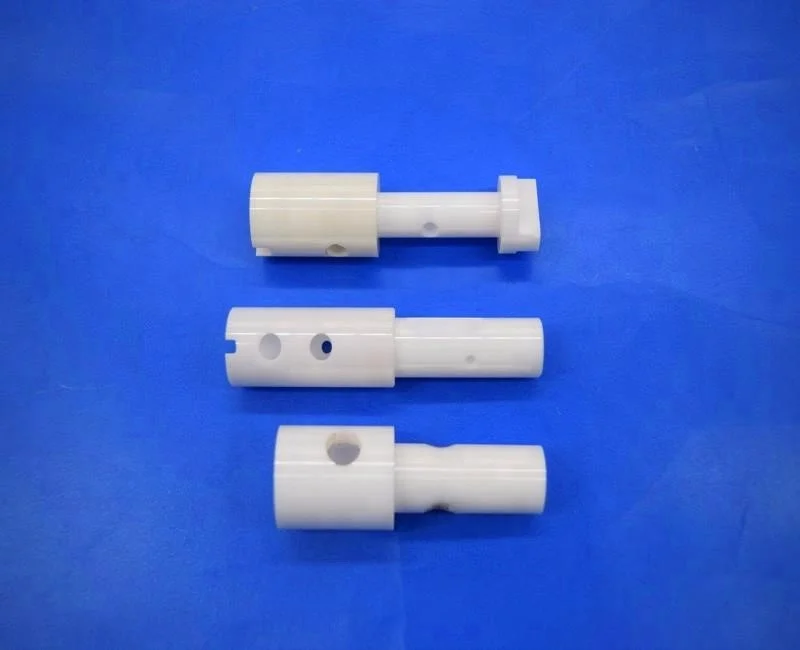

Высококачественный гидравлический алюминиевый керамический обратный клапан/поршневой

- Категория: Керамические клапаны >>>

- Поставщик: Dongguan,Mingrui,Ceramic,Technology,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-20-2025 | 0.19 $* | 0.96 $* |

| Aug-20-2025 | 0.46 $* | 0.19 $* |

| Jul-20-2025 | 0.33 $* | 0.69 $* |

| Jun-20-2025 | 0.71 $* | 0.9 $* |

| May-20-2025 | 0.89 $* | 0.85 $* |

| Apr-20-2025 | 0.96 $* | 0.94 $* |

| Mar-20-2025 | 0.89 $* | 0.25 $* |

| Feb-20-2025 | 0.40 $* | 0.16 $* |

| Jan-20-2025 | 0.10 $* | 0.55 $* |

Характеристики

High pressure Hydraulic alumina ceramic check valve with reliable quality

Features:

Alumina ceramic is the most mature of the engineering ceramics, offering excellent electrical

insulation properties together with high hardness and good wear resistance,but relatively low

strength and fracture toughness.Alumina ceramics are generally white but may also be pink or

ivory.The color is derived from either the sintering additives or impurities in the raw materials.

1. High hardness.

2. High heat resistance : Alumina ceramic has excellent thermal stability,which means that it is

widely used in areas where resistance to high temperatures is essential.

3. Good wear resistance : Alumina ceramic is the material of choice for alumina wear parts.

4. High electrical resistivity : Alumina is an electrically insulating material.

5. High corrosion resistance : It is insoluble in water and only slightly soluble in strong acid and

alkaline solutions. Good chemical stability of alumina leads to high corrosion resistance.

Performance:

Alumina Content | Unit | 80-85% | 90-96% | > 99.5% | 99% |

General Application |

| Lower Cost Electrical & Mechanical | High Strength, Wear Resistant, Electronic, Insulating, Mechanical, Structural & Metalizing | Extremely High Purity, Temperature & Strength; Excellent Corrosion & Wear Resistance | Porous, Easily Degassed & Machinable |

Porosity | % | 0-.05 | 0-.05 | 0-.05 | Variable |

Density | gm/cm3 | 3.45-3.50 | 3.55-3.75 | 3.75-3.95 | 2.4 |

Flexural Strength | kpsi | 35.0-40.0 | 40.0-50.0 | 50.0-55.0 | - |

Comprehensive Strength | kpsi | 260.0 | > 300.0 | > 300.0 | - |

Tensile Strength | kpsi | 15.0-20.0 | 20.0-28.0 | 20.0-28.0 | - |

Linear Coefficient of Thermal Expansion | (cm/cm/°C) 25-300°C 25-700°C | 5.9X10-6 6.5X10-6 | 6.3X10-6 7.0X10-6 | 6.5X10-6 7.5X10-6 | 6.5X10-67.5X10-6 |

Dielecctric Constant at 25°C | 1 MH 10 MH | 8.5-8.9 8.4-8.8 | 9.2-9.8 9.0-9.6 | 9.5-9.9 9.3-9.7 | - |

Dielectric Strength | Volt/mil | 200 | 225 | 225 | - |

Te Value | °F °C | 1472 800 | > 1832 > 1000 | > 1832 > 1000 | > 1832 > 1000 |

Thermal Conductivity at 25°C | cal/sec/cm2/cm/°C | .03-.04 | .04-.06 | .07-.08 | - |

Safe Use Temperature | °F °C | 2550 1400 | 3000-3100 1650-1700 | 3275 1800 | 3275 1800 |

ABOUT US

CULTURE

Ming Rui Ceramics Limited has been specializing in the manufacture of Zirconia ceramics part and Alumina ceramic parts used in medical instruments,textile machines, e-cigarattes, dispensing machines, lithium battery, auto mobile, petrochemical industry and other high temperature and corrosive conditions for over 10 years. Consistent quality, dependable support and delivery, and innovative solutions have enabled us to expand our business world wide.

PACKAGE:

Packed in PP bags or sponge tray, then put in standard export carton packing.

DELIVERY TIME:

3-20 days after confirming order,detail delivery date should be decided according to

production season and order quantity.