Китайская Фабрика Lvdao новая технология высокопроизводительный полипропиленовый полиэтиленовый пленочный пластиковый

- Категория: >>>

- Поставщик: Yuyao,Lvdao,Plastic,&,Rubber,Machinery,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-15-2025 | 530695.33 $* | 557230.21 $* |

| Aug-15-2025 | 526235.55 $* | 552547.14 $* |

| Jul-15-2025 | 441502.45 $* | 463577.7 $* |

| Jun-15-2025 | 517316.43 $* | 543182.49 $* |

| May-15-2025 | 450422.47 $* | 472943.92 $* |

| Apr-15-2025 | 508397.21 $* | 533817.31 $* |

| Mar-15-2025 | 503937.4 $* | 529134.12 $* |

| Feb-15-2025 | 499477.1 $* | 524451.84 $* |

| Jan-15-2025 | 495018.95 $* | 519769.14 $* |

Характеристики

Feature:

1.It has cylinder regulating value.

2.It adopt pure copper motor.

3.Long service life.

4.easy to operate

Production information:

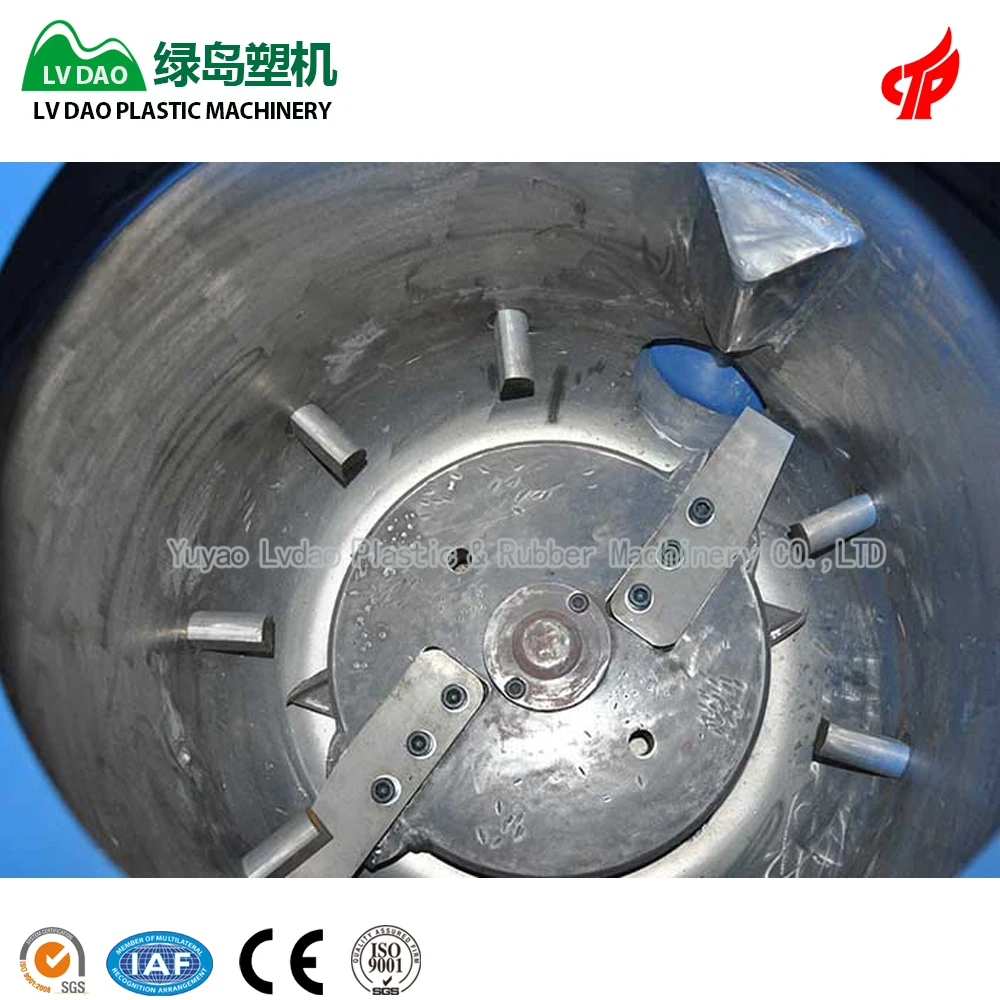

Plastic Agglomerator can directly recycle the waste plastic films and other products less than 2 mm wall thickness into granules, like films made of soft PVC, HDPE, LDPE, PP and other thermo plastics. When the waste plastic is put into the chamber, it will be cut into smaller chips due to the crushing function of the rotating knife and fixed knife.

During the crushing processing, the material that soaked up lots heat from the frictional movement of material being crushing and the material will be going to become semi-plasticizing state.

Before it sticks each other completely, the cold water pre-prepared is sprayed into the material being crushed. So the material being crushed will become small particles or granules.

Working Principle:

When the waste plastic is supplied into the chamber of such machine, it will be cut into smaller chips due to the crushing function of the rotating knife and fixed knife. During the crushing processing, the material that soaked up lots heat from the frictional movement of material being crushing and the wall of container will be going to become semi-plasticizing state. The particles will stick with each other due to the function of plasticization. Before it sticks each other completely, the cold water pre-prepared is sprayed into the material being crushed. The water will be evaporated off quickly and the surface temperature of material being crushed drop down quickly also. So the material being crushed will become small particles or granules. It is easy to recognize the particles by different size and can be colored by using of color agent being putted into the container during the crushing processing.

Model:

LDZ-300

Parameter trable

| Model |

Power (kw) |

Weight(kg) |

Out put (kg/h) |

Roate speed r/min |

Effective volume(L)

|

| LDZ-100 | 37 | 1000 | 60-100 | 1050 | 100 |

| LDZ-200 | 45 | 1200 | 100-150 | 1050 | 150 |

| LDZ-300 | 55 | 1800 | 150-200 | 950 | 225 |

| LDZ-300 | 75 | 2000 | 200-300 | 950 | 225 |

| LDZ-500 | 90 | 2500 | 300-350 | 850 | 450 |

| LDZ-600 | 110 | 2700 | 350-450 | 750 | 550 |

| LDZ-800 | 132 | 3000 | 500-600 | 750 | 750 |

| LDZ-1500 | 160 | 5000 | 900-1200 | 660 | 1400 |

Yuyao lvdao plastic and rubber machinery Co.,Ltd.(lvdao plastic machinery) is a professional manufacture of plastic Recycling machine and pelletizing extrueder,and it has been in the plastic Recycling field for almost two decades.

Our branch Office put into operation in August 2011.The site covers an area of twenty thousand square meters.We have modern technology center and all kinds of processing equipment with testing facilities. Our company always take customer satisfaction as purpose,customers constantly support and identity. Always continue expanding our market and promoting our technology progess.

Our equipment have already had many invention patents now. Passed ISO9001:2008 certification. The plastic pelletizing unit has passed the CE authentiction security. In 2007 our LDA series are on national torch plan projects. In2008 Our company was awarded the ningbo high-tech enterprises.And the company take the national innovation fund projects in 2009.

In-sale services:

1.We supply a series of machine about plastic pelletizing;

2.Accroding to various kinds of material and output, we will provide suitble pelletizing line for you. In case you spend extra money.

3.We can provide machine tests of the whole line if you can send the raw material. Therefore, you can know the condition of machine on the spot or by video we send you.

After-sale services:

1.Engineer service to the customer and training the workers for client;

2,We have 24-hour team to solve the after-sale problem;

3.We have free spare parts with the machine;

4.We always update the new technology to every customer;

5.One year warranty for our machine(except quick-wear parts),under the normal use.

Q:Are you machinery factory or trading company?

A:We are machinery factory with 20 years experience in Ningbo. And we can export machines by ourselves.

Q: Which kind of machine do you make?

A: We mainly produce plastic recycling machine,pelletizing machine and other auxiliary machine , according to the different raw material, different output and different industrial voltage in working place,you can choose different machines.

Q: How can we visit your company and machines?

A:Our factory is located in Ningbo City,near Shanghai and Hangzhou. About 3 hours away from Shanghai International Airport.

Q:Can you customized machine?

A:We can make the products following the customers' requirement,like the shape,size,color,logo and other spec details.

Похожие товары

Машина для горячего плавления kiwex eps

Высококачественная машина для переработки полиэтиленовой пленки

Данные ресурс не является интернет-магазином, а лишь содержит ссылки на международную торговую площадку Alibaba.com