Горячая Распродажа машина для производства нетканых материалов PP Spunlace высокого

- Категория: Nonwoven Machines >>>

- Поставщик: Wuxi,Ange,Environmental,Tech,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-16-2025 | 39568.1 $* | 41546.95 $* |

| Aug-16-2025 | 39235.9 $* | 41197.96 $* |

| Jul-16-2025 | 32918.14 $* | 34564.27 $* |

| Jun-16-2025 | 38570.95 $* | 40499.24 $* |

| May-16-2025 | 33583.4 $* | 35262.43 $* |

| Apr-16-2025 | 37905.81 $* | 39800.47 $* |

| Mar-16-2025 | 37573.87 $* | 39452.7 $* |

| Feb-16-2025 | 37240.86 $* | 39102.81 $* |

| Jan-16-2025 | 36908.90 $* | 38753.64 $* |

Характеристики

Hot Sale PP Spunlace Nonwoven Fabric Making Machine with High Quality

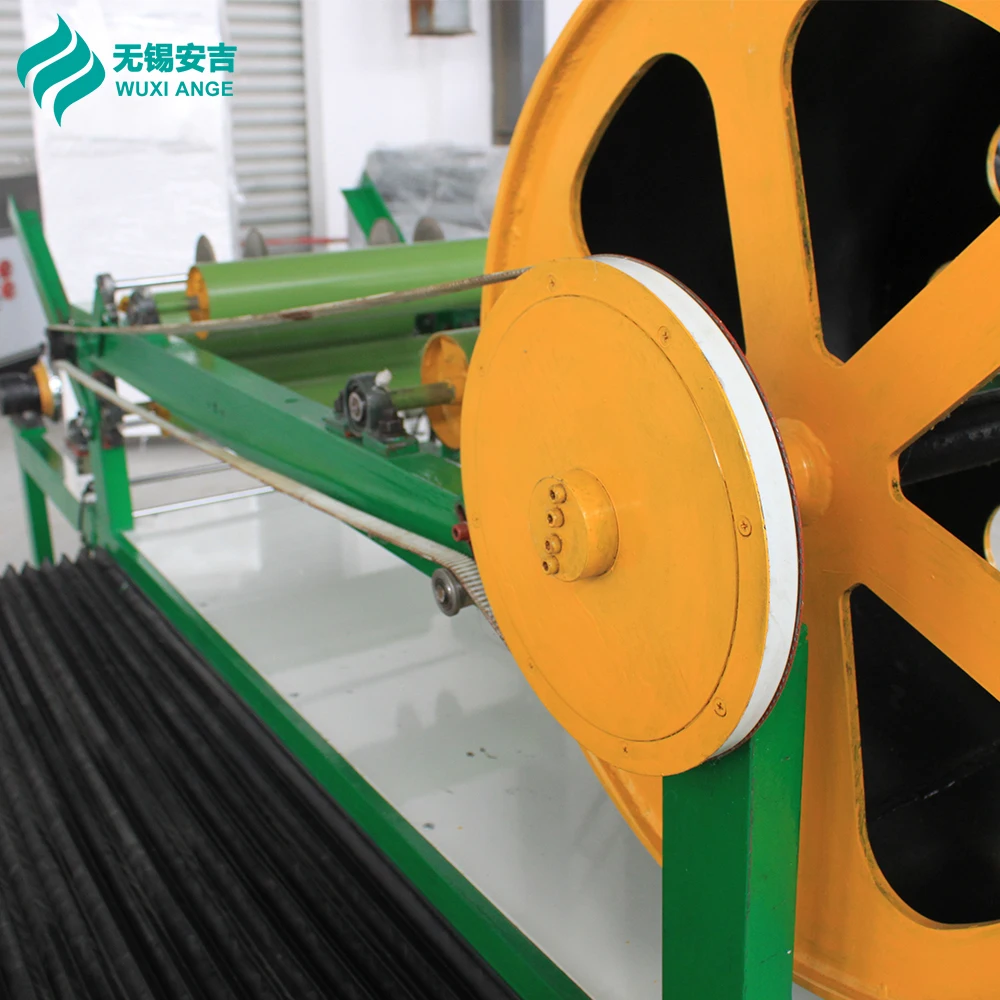

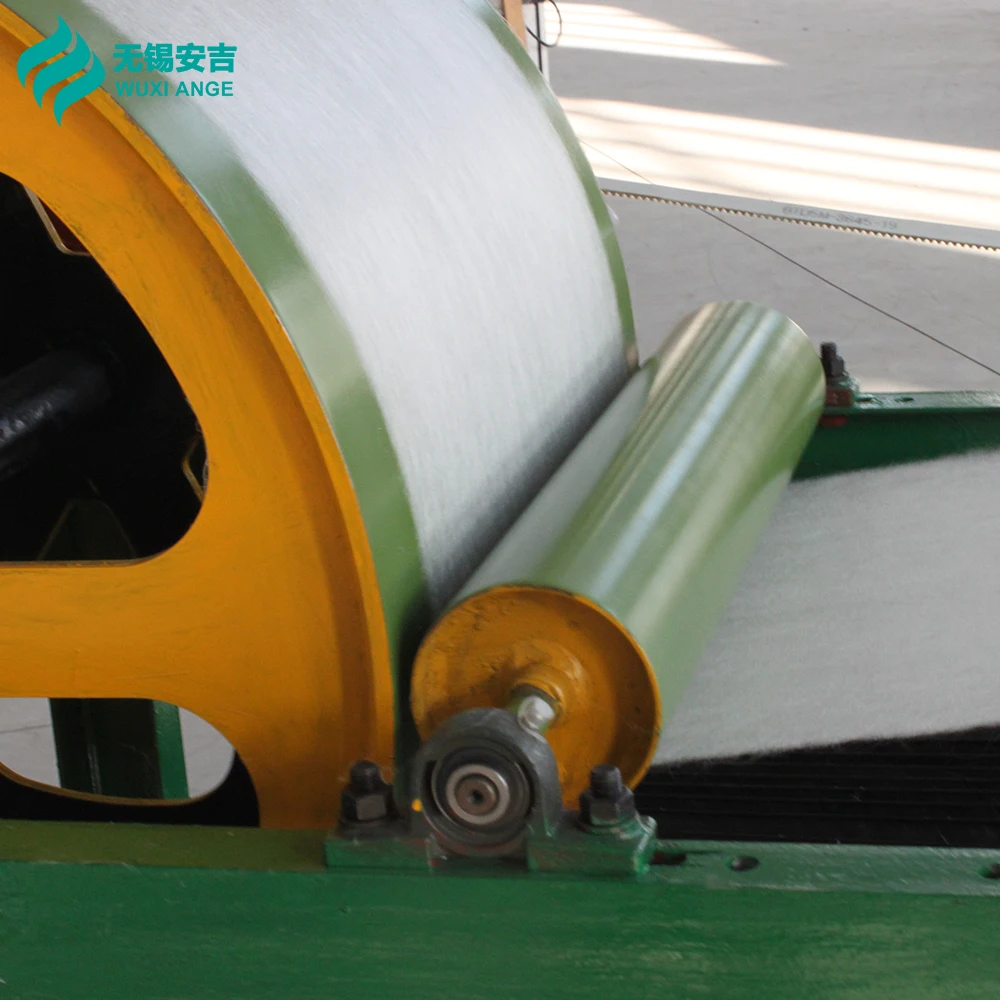

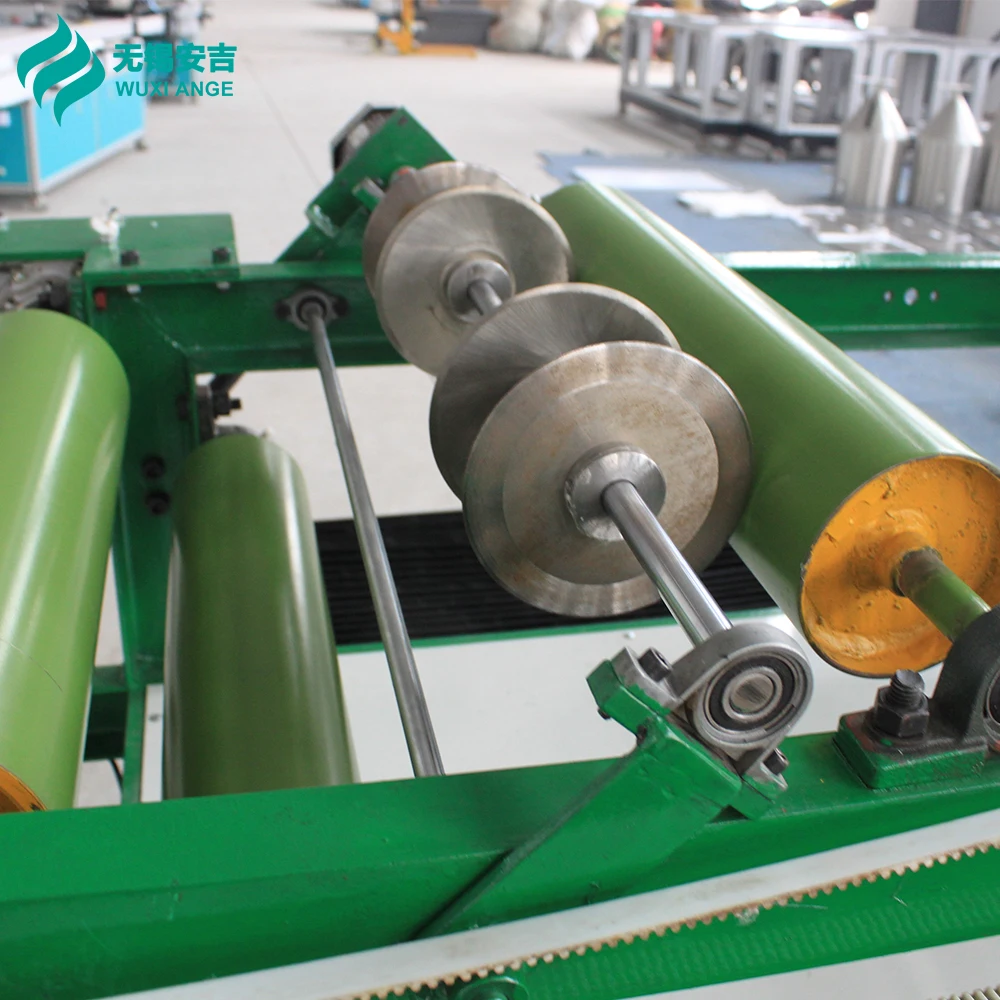

PP melt blown nonwoven fabric production line is an equipment that used to produce pp melt blown nonwoven fabric which are widely used both in face mask and medical industry.

Principle

Auto Feeder feeds 100% new drawing class polypropylene into Extruder. Then pp material are melt by heating through Extruder. Roots Blower blows the air into Air Heater and then the heated air will blow the liquid melted polypropylene materials through the Mold (with hundreds of small holes in the mold ), and finally threaded materials arrive at the Receiving car. Receiving car can be customized.

Parameter | ||||||

Raw Material | 100% New Draming Class Polypropylene MFR:800-1500 | |||||

Fiber micro | 15-30μm | |||||

Fabric Width | 0-1000mm | |||||

Fabric Weight(GSM) | 15-200 gsm | |||||

Fabric Thickness | 2-5mm | |||||

Capacity | 250-300KGS/24H or 500KG/24H or 1~1.5ton/24H PS:Room temperature affects production capacity,10-30℃ is highly recommended | |||||

Actual Running Power | 20-25KWH | |||||

Total Installed Power | 37KW | |||||

Mold Width | 300-700mm 200-1200mm | |||||

Mole Hole Size | 0.2-0.4mm(can be customized) | |||||

Application

1. oil absorption material

2. Intermediate filter layer

Training: 2 solutions

1. Welcome to stay in our factory for a long-term training 7~14days until you master all the skills.

2. We provide an installing and training service to your factory in 7~14days until you master all the skills and you should take care of the plane ticket, hotel and living cost during this time.

Our service

1.All our machines are tested before shipping out to ensure there is no potential problem.

Warranty: 1year.

2.If non-human cause of quality problems occurs, we provide EXW item free part.

3.If this cause by incorrect operations, we won't provide free replacement.

4.We provide detailed instruction and maintenance documents about how to operate the machines as well as unlimited long term support by email or phone call.

Packing details: every part is packed by plastic film, and all are packed in wooden case.

Delivery time: usually 20-25 days after the deposit.

If you have any questions, our engineers are always available to give a comprehensive answer with their 30-year experience in filter making industry.

Our engineers can speak well English.

About us

WuXi ANGE Environmental Technology Company Limited is found in 2000 with 1,000,000 rmb registered capital. We are an ISO and CE cerfiticated manufacturer specializing in PP Spun Filter Cartridge Making Machine for Water Treatment, pp string wound filter making machine, CTO active carbon filter cartridge block making machine/ production line, and PP melt blown non woven fabric making machine with 20 years' experience in machine design and filter making. Our clients are full of the world: USA, Japan, Korea, Singapore, Thailand, Russia, Malaysia,

Egypt, Taiwan, Ukraine, Turkey, Brazil, Argentina, and Indonesia...

Welcome to visit our factory and check the excellent machines by yourself. Let's together contribute to build a brilliant environment protection industry!

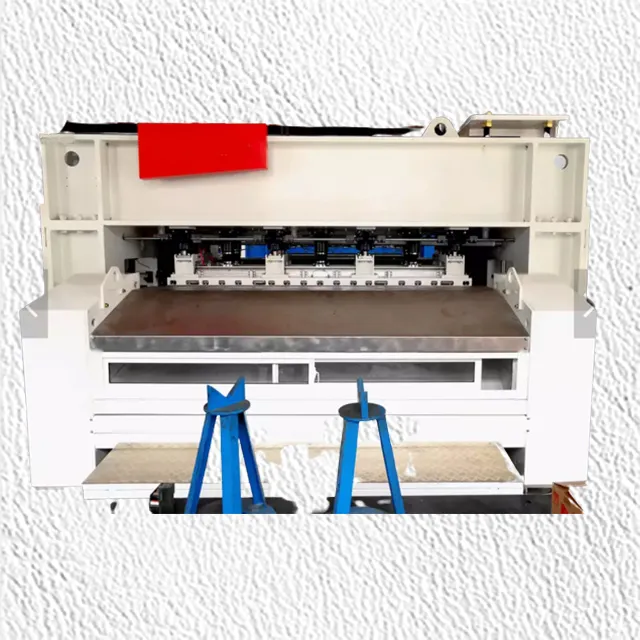

CTO Active Carbon Filter Making machine

2018 New Design :100% No Dust,Easily passed the EIA

PP Melt Blown Filter Cartridge Production Line

Modle: 1E1M/1E2M/2E2M/3E3M

PP String Wound Filter Production Line

Machine: 10"/20"/30"/40"