Интумезирующий опорный коврик из керамического волокна для однослойного каталитического

- Категория: Other Ceramic Fiber Products >>>

- Поставщик: Nanning,Elaiter,Environmental,Technologies,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-17-2025 | 0.56 $* | 0.21 $* |

| Aug-17-2025 | 0.56 $* | 0.84 $* |

| Jul-17-2025 | 0.21 $* | 0.20 $* |

| Jun-17-2025 | 0.82 $* | 0.88 $* |

| May-17-2025 | 0.63 $* | 0.48 $* |

| Apr-17-2025 | 0.46 $* | 0.45 $* |

| Mar-17-2025 | 0.3 $* | 0.6 $* |

| Feb-17-2025 | 0.65 $* | 0.6 $* |

| Jan-17-2025 | 0.62 $* | 0.18 $* |

Характеристики

We offer a variety of catalytic converter support mats that provide high value, cost effective solutions for mechanical support of honeycomb ceramic substrate used in catalytic converters.

Function of support mat

lFixation and protecting of honeycomb ceramic substrate.

lAirproof and preventing exhaust gas leak.

lExcellent insulation properties and avoiding overheating of the shell.

lSound insulation and exhaust systems noise reduction.

Existing product include

lIntumescent support mat.

lNon-intumescent support mat.

lEdge seal support mat.

lMultilayer composite support mat.

lGraphite intumescent support mat.

Intumescent support mat description

The intumescent support mat contains the high temperature expansion of vermiculite. It is used for most conventional catalytic converter, widely used in gasoline and diesel systems mounting designs and applications.

Technical data (Model Number: ELT100)

Density (g/m2) | 2100 | 2600 | 3100 | 3662 | 4070 | 4300 | 4695 | 5200 | 6200 | 8140 |

Weight tolerance (%) | ±10 | ±10 | ±8 | ±8 | ±8 | ±8 | ±8 | ±8 | ±8 | ±8 |

Standard thickness (mm) | 3.33 | 4.15 | 4.90 | 5.40 | 6.02 | 6.32 | 6.90 | 7.65 | 9.12 | 12.04 |

Thickness tolerance (%) | ±12 | ±12 | ±12 | ±12 | ±12 | ±12 | ±12 | ±12 | ±12 | ±12 |

Applicable space lower limit (mm) | 1.75 | 2.17 | 2.84 | 3.06 | 3.40 | 3.58 | 3.92 | 4.15 | 5.17 | 7.16 |

Applicable space upper bound (mm) | 2.60 | 3.25 | 3.88 | 4.58 | 5.10 | 5.38 | 5.87 | 6.24 | 7.74 | 8.10 |

Packing density (g/cm3) | 1.0 g/cm3(Density range 0.8-1.2 g/cm3) | |||||||||

Tensile strength (KPa) | ≥100 | |||||||||

Vermiculite content (%) | 45-60 | |||||||||

Ceramic fiber content (%) | 30-45 | |||||||||

Burning loss (%) | 6-13 | |||||||||

Compression ratio (%) | 40-60 | |||||||||

Initial expansion temp. (°C) | ≤410 | |||||||||

Initial expansion ratio (%) | ≥0.85 | |||||||||

750°C expansion ratio (%) | ≥1.30 | |||||||||

Long term max working temp. (°C) | 1000 | |||||||||

Non-intumescent support mat description

The non-intumescent support mats do not contain the high temperature expansion of vermiculite. It is used for gasoline system applications, especially ultra-thin wall ceramic substrate, and can also be used as the edge sealing of the expansion cushion.

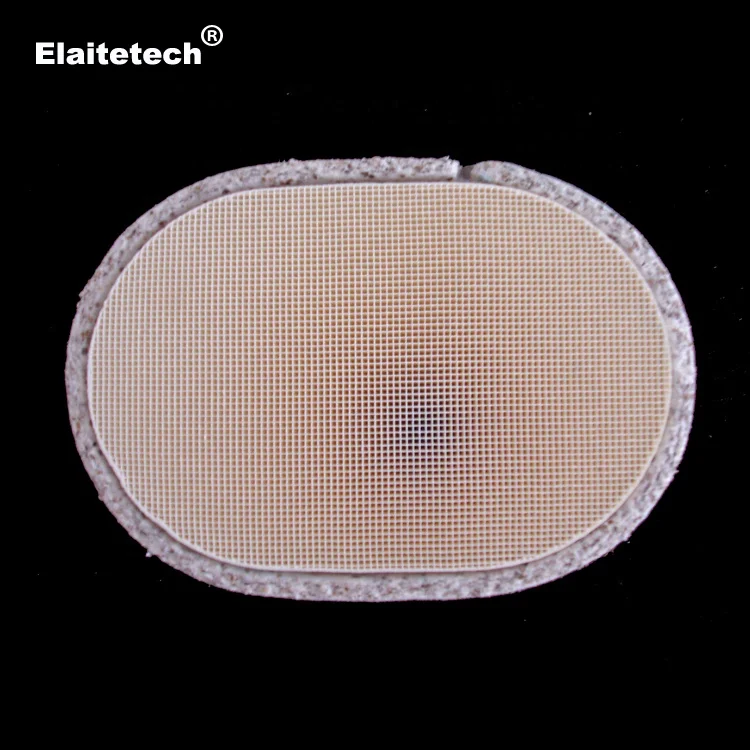

Edge seal support mat description

Model Number: ELT100/200

The edge seal support mat comprises one or two narrow strips of non-intumescent support mat on one or both sides of a wide strip of intumescent mat. It is used for close coupled and manifold catalytic converter, wide oval ceramic substrate and racetrack ceramic substrate.

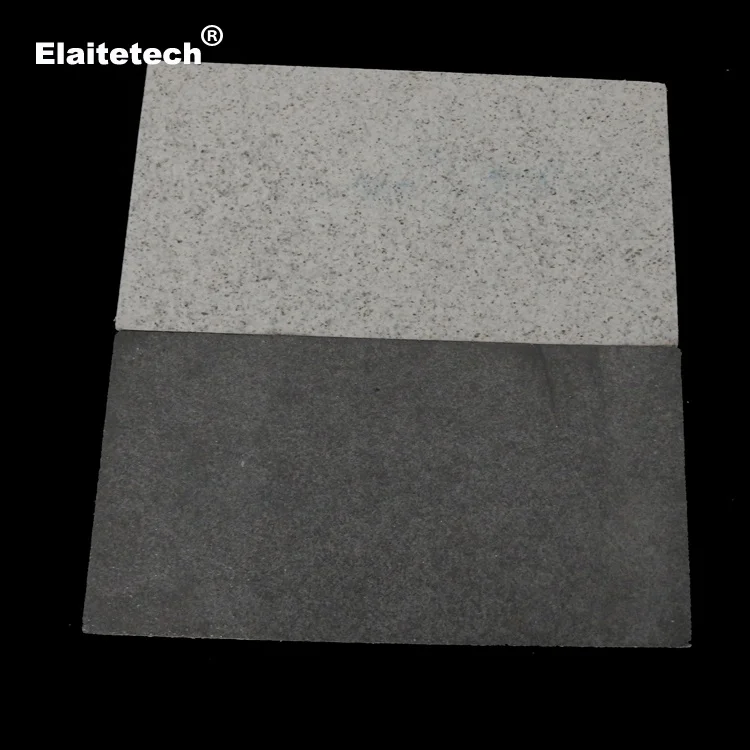

Multilayer composite support mat description

The multilayer composite support mat is normally comprises a layer of intumescent support mat and a layer of non-intumescent support mat. It is used for gasoline system applications, especially ultra-thin wall ceramic substrate.

Graphite intumescent support mat description

The graphite intumescent support mat contains the high temperature expansion of vermiculite and the expandable graphite. The support mat is used for gasoline as well as diesel systems mounting designs and applications, especially diesel particle filters.