RTV 2 Жидкая силиконовая резина 1:1 полупрозрачная для обуви

- Категория: Silicone Rubber >>>

- Поставщик: Shenzhen,Yijiasan,Silicone,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Aug-17-2025 | 9.93 $* | 9.37 $* |

| Jul-17-2025 | 7.9 $* | 7.48 $* |

| Jun-17-2025 | 9.74 $* | 9.50 $* |

| May-17-2025 | 9.78 $* | 9.11 $* |

| Apr-17-2025 | 7.88 $* | 7.77 $* |

| Mar-17-2025 | 9.56 $* | 9.1 $* |

| Feb-17-2025 | 8.72 $* | 8.73 $* |

| Jan-17-2025 | 8.87 $* | 8.90 $* |

Характеристики

Description

YJS-620 is a kind of two part silicone rubber in addition cure or platinum cure type with mixing ratio of 1:1 or 10:1 . It can cure at room temperature as well as under heat . It’s a kind of food grade silicone and mainly used for mold making.

addition cure liquid silicone rubber for silicone insoles has 2 main parts application:

First: making many kinds of molds:

Making molds for:

Low melt metals (mold life can be short), Cement, Concert,concrete stones, wax molds, PU molds, resin molds, gypsum casting, candle molding, chocolate , candy and any other food product mold making, prototyping etc.

Making molds for food grade products: chocolate molds, cake molds, sugar molds,ect.

Making molds for life casting: real hand molds, real feet molds, dildos molds, sex doll molds, ect.

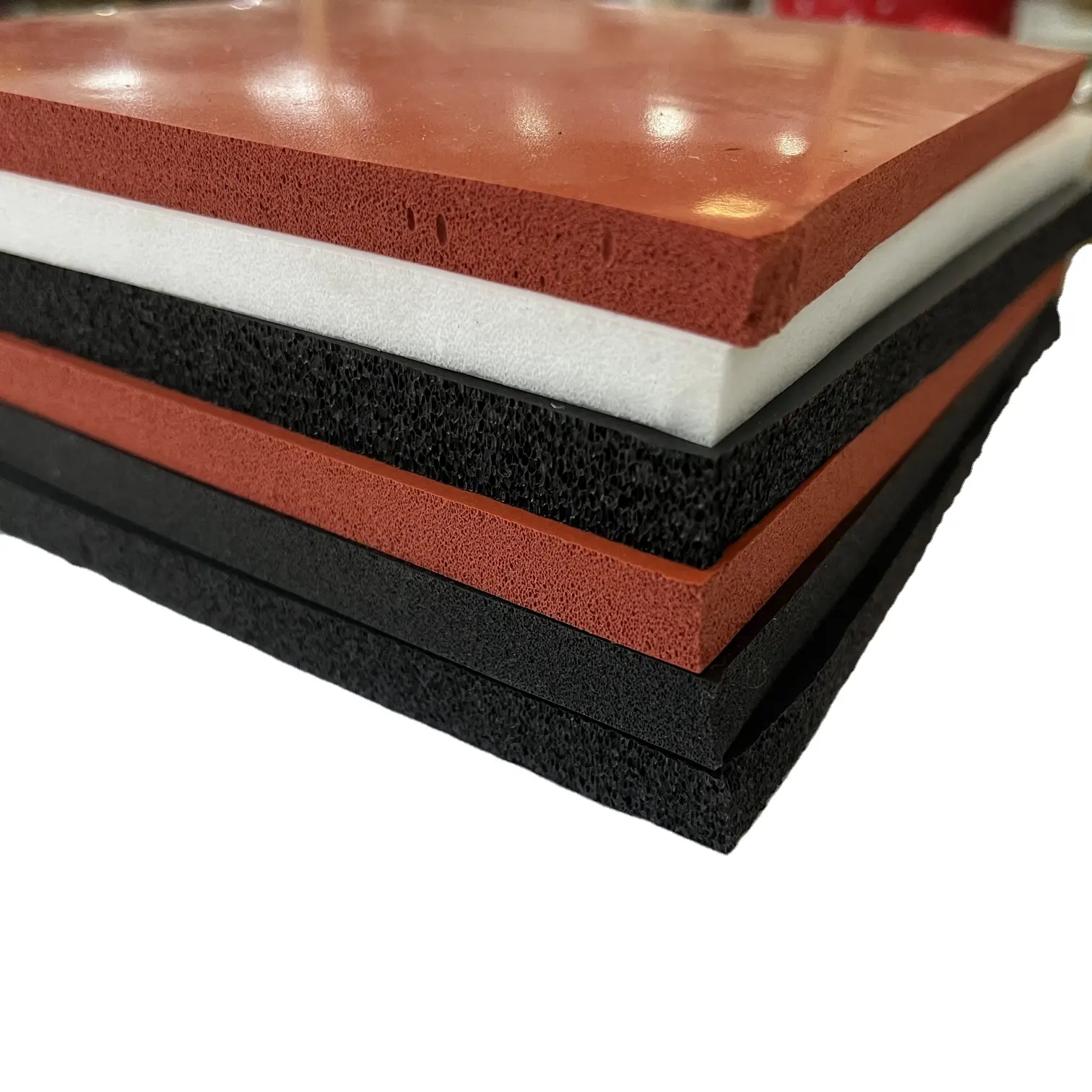

Second: make silicone products, like silicone insoles, silicone gel, ect. and prosthetics arms, prosthetics hands, prosthetics foot, prosthetics legs, ect. and silicone mask, skin, ect. sex dolls, sex toys, ect.

YJS-620 serries are most suitable and excellent to make silicone insoles and relative foot health care products, such as

forefoot pain, heel lifts, insoles, foot orthotics, arch supports, heel cushions and pads, etc. It is a medical grade silicone

that resists to bacterial growth and does not dry out. It is also hypo-allergenic, non-toxic and odorless.

Typical general characteristics | Inspection Method | Value |

Product data (Catalyzed A+B) | YJS-620 | |

Hardness | Shore A | 20±2 |

Mix Ratio | A:B | 100:2 |

Color | / | white |

Pot life | 25 °C (77F) | 30-40 |

Curing time | 25 °C (77F) | 3-4 |

Mixed viscosity | mPa.s | ≥3.1 |

Tear-strength | kg/cm | 20±2 |

Tensile-strength | M.pa | 18000±2000 |

Elongation | % | ≥480% |

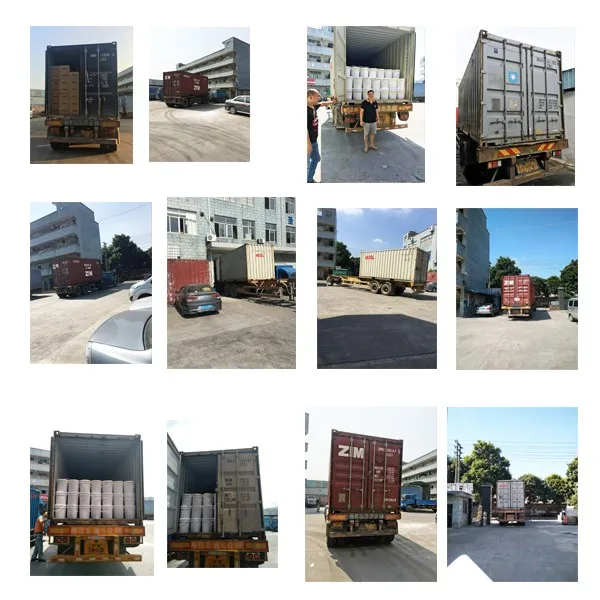

Shrinkage | % | ≤0.2% |

Shenzhen YiJiaSan Silicone Co., Ltd., is a collection of organic silicone new materials research and development, production, sales and service in one of the major raw material manufacturer. Over years of formed a product research and development, quality supervision, market operation, service and consulting, etc of a complete operation system. we have advance organic silicone production equipment, professional matching analysis testing scientific instruments and strong production technology, and have a number of highly qualified technical management personnel and with rich practical experience of skilled workers. Products with stable quality and good services sold well all over the country and exported to Europe, Middle East, North&South America, Southeast Asia, more than 90 countries and regions, deeply the general customers the consistent high praise and trust.

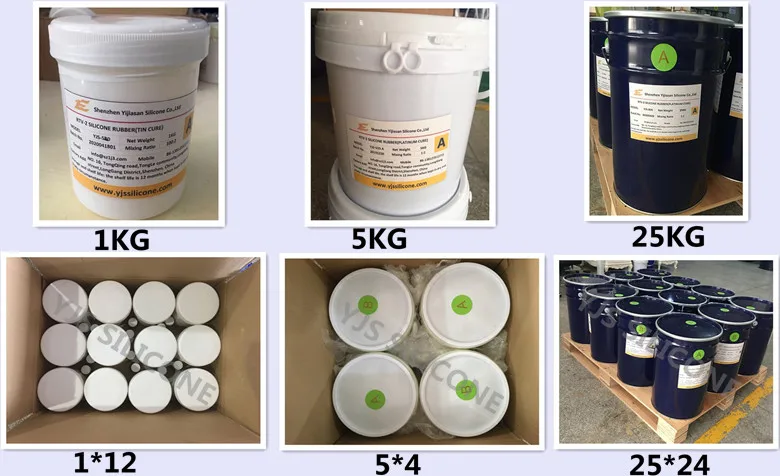

5KG/drum vacuum packing for part A + 5KG/drum vacuum packing for part B

20KG/drum vacuum packing for part A + 20KG/drum vacuum packing for part B

200KG/drum packing for part A +200KG/drum packing for part B

Notes: Please finishes all the steps within the operation time. If not, it will cause cross linking reaction, and no more further steps will be available. So, we have to pay attention to the pot life and curing time.