Вес резиновой конвейерной

- Категория: Ремни резиновые >>>

- Поставщик: Zhejiang,Fuda,Rubber,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-19-2025 | 0.55 $* | 0.49 $* |

| Aug-19-2025 | 0.73 $* | 0.74 $* |

| Jul-19-2025 | 0.11 $* | 0.57 $* |

| Jun-19-2025 | 0.86 $* | 0.69 $* |

| May-19-2025 | 0.72 $* | 0.95 $* |

| Apr-19-2025 | 0.53 $* | 0.25 $* |

| Mar-19-2025 | 0.12 $* | 0.94 $* |

| Feb-19-2025 | 0.12 $* | 0.29 $* |

| Jan-19-2025 | 0.0 $* | 0.73 $* |

Характеристики

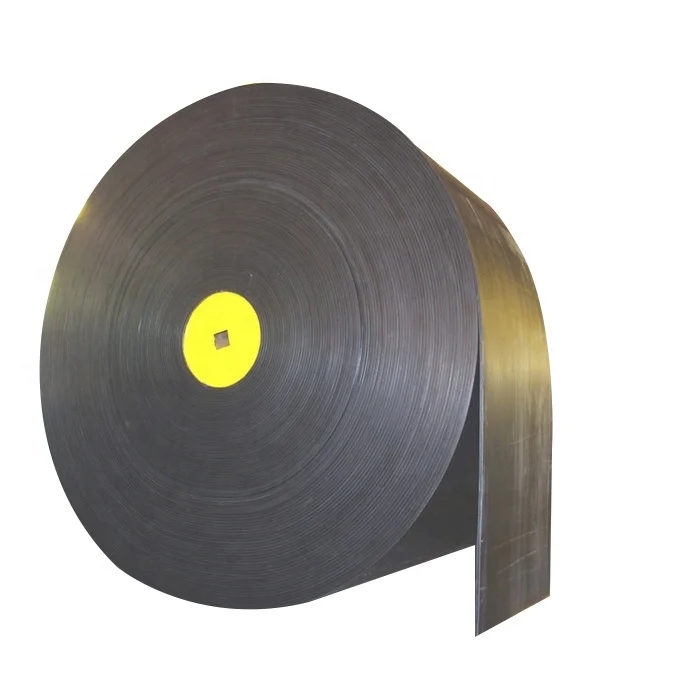

EP / NN / CC /TC CONVEYOR BELTS

We are a nation chemical designated enterprise in rubber conveyor belt line and ISO certified manufacturer and exporter of superior quality conveyor belts, which are also called as conveyor belting. These conveyor belts are compatible with long distance conveying with high load, speed & impact. These conveyor belt find usage in diverse industries for material handling applications.

Conveyor belts type include

· Anti-split conveyor belts

· Anti-abrasion conveyor belts

· Common conveyor belts

· Acid-alkali resistant conveyor belts

· Heat-resistant conveyor belts

· Cold -resistant conveyor belts

· Oil -resistant conveyor belt

Conveyor belt specification and technical data sheet

Fabric type | Fabric structure | Fabric type | Fabric thickness | Cover rubber thickness | Width | Length | ||

warp | weft | Upper | Lower | |||||

EP | EP | EP | EP-100 | 0.75 | 1.5-8 | 0-4.5 | 400-2500 | <=300 |

EP-150 | 0.8 | |||||||

EP-200 | 0.90 | 500-2500 | ||||||

EP-250 | 1.15 | |||||||

EP-300 | 1.25 | |||||||

EP-400 | 1.45 | 800-2500 | ||||||

EP-500 | 1.55 | |||||||

Fabric type | Fabric structure | Fabric type | Fabric thickness | Cover rubber thickness | Width | Length | ||

warp | weft | Upper | Lower | |||||

NN | NN | NN | NN-100 | 0.75 | 1.5-8 | 0-4.5 | 400-2500 | <=300 |

NN-150 | 0.8 | |||||||

NN-200 | 0.9 | 500-2500 | ||||||

NN-250 | 1.15 | |||||||

NN-300 | 1.25 | |||||||

NN-400 | 1.45 | 800-2500 | ||||||

NN-500 | 1.55 | |||||||

We could offer belt with cover grade in accordance to International standard such as DIN 22102, RMA, AS 1332, SABS 1173/2000, IS 1891, BS 490, JIS K 6322, etc.

Standards | Cover Rubber | Adhesion | ||||

Tensile Strength | Elongation at break | Abrasion | Cover to Ply | Cover to Ply | Ply to Ply | |

DIN 22102 | Mpa | % | mm3 | N/mm (≤1.5mm) | N/mm (>1.5mm) | N/mm |

DIN 22102-Z | 15 | 350 | 250 | 3.5 | 4.5 | 5 |

DIN 22102-W | 18 | 400 | 90 | 3.5 | 4.5 | 5 |

DIN 22102-Y | 20 | 400 | 150 | 3.5 | 4.5 | 5 |

DIN 22102-X | 25 | 450 | 120 | 3.5 | 4.5 | 5 |

Standards | Cover Rubber | Adhesion | ||||

Tensile StrengTD | Elongation at break | Abrasion | Cover to Ply | Cover to Ply | Ply to Ply | |

AS 1332 | Mpa | % | mm3 | N/mm (≤1.9mm) | N/mm (>1.9mm) | N/mm |

AS 1332-N17 | 17 | 400 | 200 | 4 | 4.8 | 6 |

AS 1332-M24 | 24 | 450 | 125 | 4 | 4.8 | 6 |

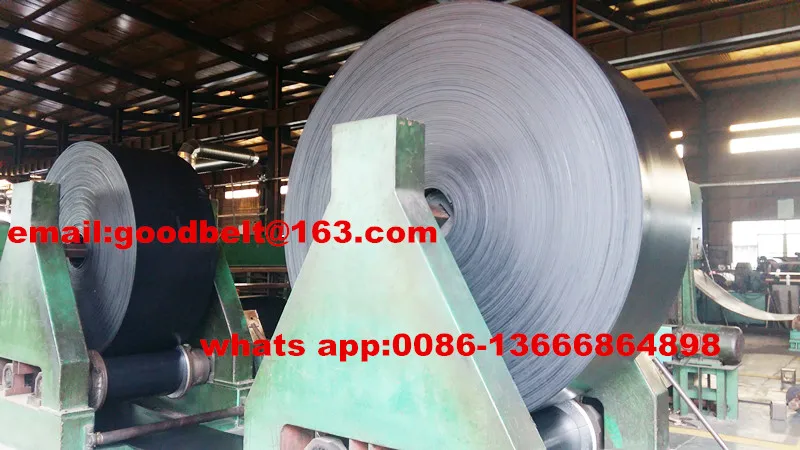

Conveyor belt production process 7 points as following

1.conveyor belt raw materials (nature rubber EP NN cotton)

2.conveyor belt rubber smelting(rubber smelting with the internal mixer and open mill)

3.conveyor belt shapping(shapping up the belt,we have 3 sets wraping line )

4.conveyor belt vulcaniaztion(we have 5 sets double volcanization production machines )

5.conveyor belt finished photos

6. conveyor belt quality control

7. conveyor belt package and delivery