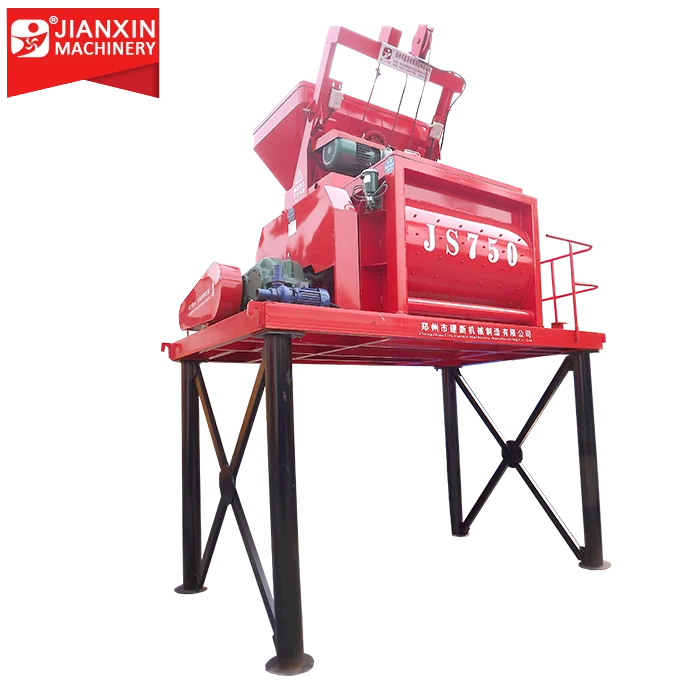

Бетономешалка хорошей производительности 0 75 м3 с подъемником и водяным

- Категория: Concrete Mixers >>>

- Поставщик: Zhengzhou,Jianxin,Machinery,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-17-2025 | 0.80 $* | 0.3 $* |

| Aug-17-2025 | 0.94 $* | 0.8 $* |

| Jul-17-2025 | 0.76 $* | 0.93 $* |

| Jun-17-2025 | 0.23 $* | 0.93 $* |

| May-17-2025 | 0.4 $* | 0.23 $* |

| Apr-17-2025 | 0.72 $* | 0.28 $* |

| Mar-17-2025 | 0.98 $* | 0.61 $* |

| Feb-17-2025 | 0.23 $* | 0.23 $* |

| Jan-17-2025 | 0.93 $* | 0.68 $* |

Характеристики

Introduction - Concrete Mixer 0.75m3 with Lift

JS series of concrete mixer 0.75m3 is the dual-axial mixing machine, which has double superiority to do independent operations alone, and to form a simple type concrete mixing station with PLD series ingredients machine,and can also provide the supporting host machine to mixing station.

It could be applied to all kinds of large, medium and small precast component factories and roads, bridges, water conservancy, wharf, and other industrial and civil building engineering. It could be used to mix the hard concrete, plastic concrete, liquidity concrete, light weight aggregate concrete and various kinds of mortars, and it is an efficient type of machine with very extensive application.

This series of products are designed with reasonable structure, novel layout and convenient usage and maintenance, including them(JS1500B, JS2000, JS3000 adopts Italian Sicoma Technology), Users can use it with their own tip lorry, dump lorry and agitating lorry, and it can also be restructured according to special requirements of users to meet their needs.

Technical parameters - Concrete Mixer 0.75m3 with Lift

Details show - Concrete Mixer 0.75m3 with Lift

JS750 Self-loading Concrete Mixer Mixing system

Twin-shaft JS750 concrete mixer mixing system consists of motor, pulley, gearbox, gear, stirring device, mixing drum and other components. The main motor is connected to the secondary gear reduction box through a belt, and finally the two horizontally-connected stirring shafts are respectively rotated by the two pairs of open gears at the same speed.

JS750 Self-loading Concrete Mixer Feeding system

When the Twin-shaft JS750 concrete mixer is feeded, the mixture to be mixed is placed in the hopper, the feeding system is started, and the wire rope pulling hopper is climbed upward. When climbing to a certain height, the hopper enters the feeding rack, the door is automatically opened, and the material is discharged into the mixing drum through the funnel.

JS750 Self-loading Concrete Mixer Discharging system

The discharging system is located at the bottom of the Twin-shaft JS750 concrete mixer and is unloaded by a manual push rod. According to customer requirements, the mixer can be produced in the form of electric push rod discharge. The connection between the discharge door and the mixing drum is sealed with a sealing plate, and the position of the sealing plate can be adjusted to ensure the purpose of sealing.

JS750 Self-loading Concrete Mixer Electrical System

The electrical control system needs to control the main drive motor of the Twin-shaft JS750 concrete mixer, the motor of the water supply system, the feeding and unloading of the motor. All electrical control components are located in the distribution box. The electrical components in the distribution box are installed on an iron plate, which is safe and reliable, and convenient for operation and maintenance.

Packing and shipping

Zhengzhou Jianxin Machinery Manufacturing Co.,Ltd locates in Zhengzhou City, is aprofessional manufacturer specialized in research, development, production, sales and services.

Founded in 1986, the 30 years history of development, our company has 2 production factory, with 26 senior mechanical engineers, 12 electrical engineers, 36 technical engineers, 128 senior welders, 6 QC members, 300 workers and all kinds lathe/precision machining equipment more than 50 sets.

Company’s”Jianxin” brand products has 8 series, 46 varieties, our main products includesHZS25-HZS240 concrete batching plant, WBZ300-WBZ800 stabilized soil mixing station, YHZS25-YHZS100 batching plant, CPM500-CPM2000 vertical planetary concrete mixer, JS500-JS4000 concrete mixer, PLD800-PLD4800 batching machine, 50T-500T cement silo, HYC3-HYC10 concrete trucks and other corresponding machines.

All machines meet National Standards, products through the ISO international quality system certification, CE certification, Export exemption certificate, and apply more 10 national patents.

| FAQ |

Q How about the quality of your products?

A Our machines are manufactured strictly according to national and international standards, and we take a test on each equipment before delivery. You can also use Trade Assurance by Alibaba for product quality protection, on-time shipment protection and payment protection.Chinese top brands or world grade brands like Siemens motors etc are equiped.

Q How about the price?

A As a manufactory, we can give you lower price than trade companies. Besides, customers from Alibaba can get a discount and ensurance.

Q Do you provide after-sale service?

A Yes. The warranty period of our machines is one year, and we have a professional after-sale service team to promptly and thoroughly solve your problems.It usually takes 1-3 days for training , 10-15 days for installation,1-2days for commission,1-2days for pre-operation.

Q Do you provide equipment operation training?

A Yes. We can send professional engineers to the working site for equipment installation, adjustment, and operation training.It's about 90-120 usd a day.

Q Can you test our samples?

A Yes. You can send your samples to us for test and analysis.

Q How long it takes to do all the installation

A It's at most 5days processing and manufacturing for single machine,for production line,at most 15days.

Q Can we visit your factory?

A Yes. You can visit our factory at anytime you want.