Износостойкий механический с высокой твердостью термоударный поворотный клапан из

- Категория: Керамические клапаны >>>

- Поставщик: Dongguan,Mingrui,Ceramic,Technology,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-20-2025 | 0.54 $* | 0.5 $* |

| Aug-20-2025 | 0.53 $* | 0.77 $* |

| Jul-20-2025 | 0.2 $* | 0.9 $* |

| Jun-20-2025 | 0.63 $* | 0.59 $* |

| May-20-2025 | 0.65 $* | 0.57 $* |

| Apr-20-2025 | 0.81 $* | 0.94 $* |

| Mar-20-2025 | 0.61 $* | 0.88 $* |

| Feb-20-2025 | 0.23 $* | 0.20 $* |

| Jan-20-2025 | 0.31 $* | 0.29 $* |

Характеристики

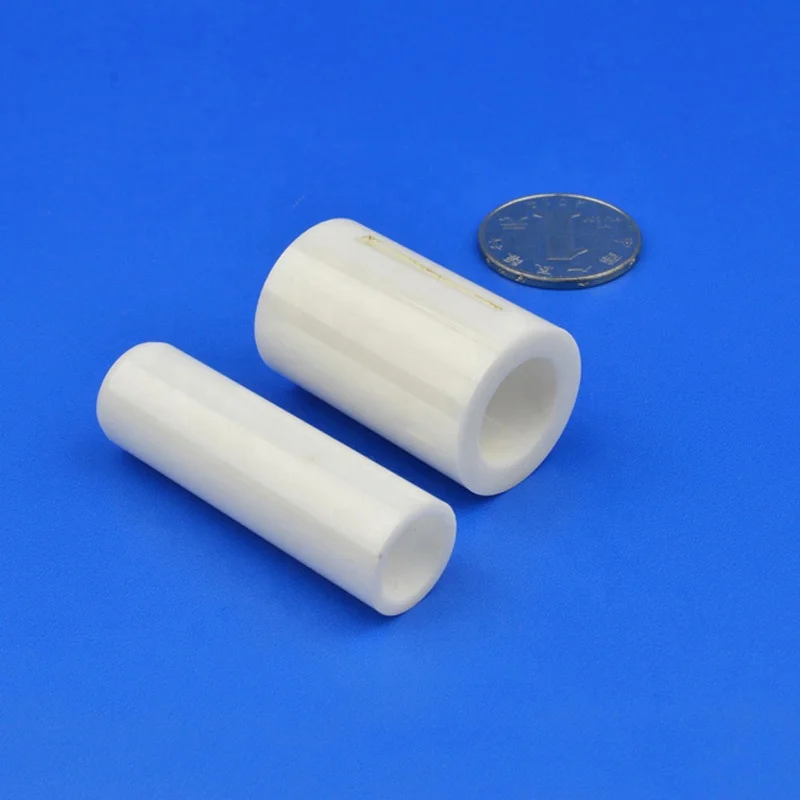

Wear Resistance Mechanical Hardness High Thermal Shock Alumina Rotary Valve

Advantages

1. Refractory.

2. Self Lubricating

3. Long Service Life.

4. Good Polished Surface.

5. Environmental and Healthy.

6. Superior Mechanical Strength.

7. High Corrosion and Wear Resistance.

8. Good Insulation Performance Precision.

9. High Temperature and Pressure Resistance.

10. High Purity Zirconia and Alumina Ceramic Material.

Due to these outstanding properties, Ceramic Products are used in a wide range of industrial and advanced appications.

And a lot of practical applications prove that our ceramic products has reached a state of high standard and quality.

Features:

1. Stong Hardness

2. High Toughness

3. High mechanical Strength

4.Resists strong acid and alkali

5.Resistant to thermal shock

6.High Mechanical Strength

7.Low Thermal Conductivity

High Polish zirconia ceramic valve

Ceramic material composition:

· 95%--99.99% Alumina (Al2O3) · Silicon Carbide · Silicon Nitride

· TTZ: Magnesia partially stabilized Zirconia (ZrO2)

· YTZP: Yttria partially stabilized Zirconia (ZrO2)

· ZDY: Yttria fully stabilized Zirconia (ZrO2)

...

The properties of ceramic:

·Excellent physical & chemical stability ·High temperature resistance

·Excellent wear & pressure & corrosion& insulation resistance and thermal conductivity...

| Properties | Units | AL2O3 | ZrO2 | SiC | Si3N4 |

| Density | g/cm3 | 3.65-3.93 | 5.95-6.0 | 3.12 | 3.23 |

| Water absorption | 0 | 0 | 0 | 0 | 0 |

| Poission`s ratio | / | 0.21-0.22 | 0.3 | 0.17 | 0.26 |

| HV hardness hv | MPa | 1650 | 1300-1365 | 2800 | 1500 |

| Flexural strength | MPa | 310 | 950 | 390 | 720 |

| Heat conductivity | W/m*k | 26-30 | 2-2.2 | 120 | 25 |

| Electrical resistivity | Ω*mm2/m | >1016 | >1015 | >103 | >1013 |

| Dielectric constant | / | 9.6 | 29 | 9.66-10.03 | / |

| Dielectric strength | KV/mm | 8.7 | 9 | / | / |

| Coefficientof thermal expansion | 10-16/k | 7.9-8.5 | 10.5 | 3 | 3.2 |

| Modulus of elasticity young`s mod | GPa | 280-340 | 210 | 440 | 300 |

| Flexural strength(700℃) | MPa | 230 | 210 | 380 | 450 |

| Compressive strength | MPa | 2200 | 2000 | 1800 | 2300 |

| Max use temperature | ℃ | 1750 | 1050 | 1550 | 1050 |

| Resistance to acid alkaline | / | high | high | high | high |

| Thermal shock resistance | T(℃) | 180-220 | 280-350 | 230-260 | / |

| Fracture toughness | MPa*m1/2 | 4.2 | 10 | 3.9 | 6.2 |

| Tensile strength | MPa | 248 | 250 | / | / |

Manufacturing parameters:

| Additional Information:

| |||||||||||||||||||||||||||||

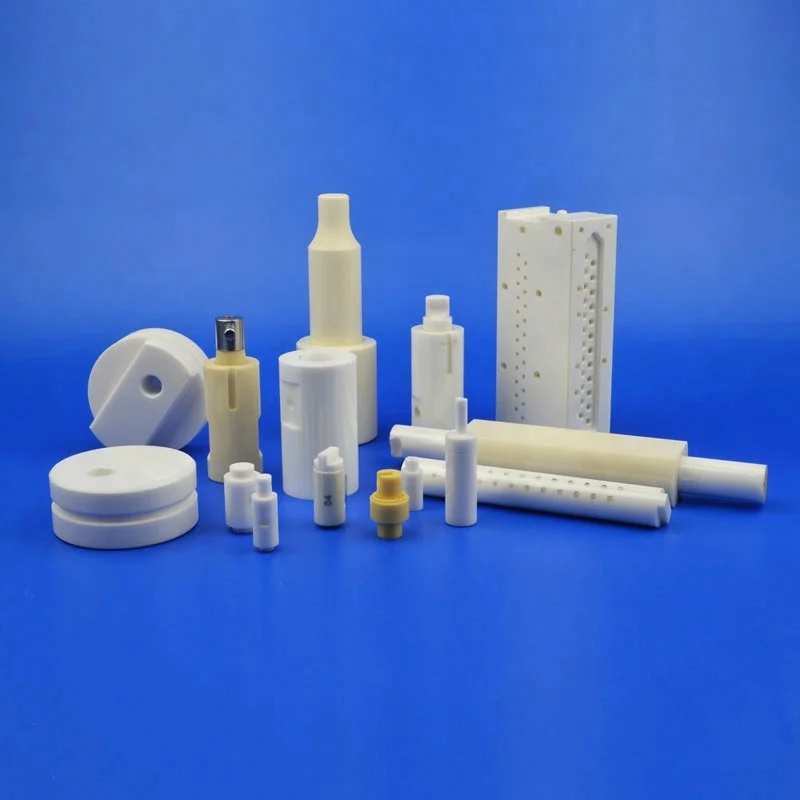

As a manufacturer of ceramic parts, we offer customization of ceramic for special sizes and shapes.High Precision, Fast Delivery Time, High Composition.

CULTURE

We are a leading manufacturer of industrial ceramic parts, who has years of R&D experience in China. And very advanced technologies in the production of zirconia and alumina ceramic tube, ceramic rod, ceramic plate, ceramic ring, ceramic sleeve, ceramic valve, ceramic piston plunger pump, and semiconductor ceramics, etc.

They are applicable to Electrical, Appliance, Mining, Oil & Gas, Energy & Power, Food & Medical, Agriculture, Aerospace, even other high-end fields.

Dongguan Mingrui Ceramic Tech. Co. Ltd.

Add: No.21 Chuangxing Rd., the 2nd Industrial Zone of

Shangsha,Chang'an town, Dongguan city, Guangdong,China

Tel: +86 0769 85090316

Fax: +86 0769 85090326

Skype: +86 18122972636

Mobile: +86 18122972636

Official website: http://www.cerampart.com/