Небольшая печь для газогенератора биомассы домашнего

- Категория: Energy Saving Equipment >>>

- Поставщик: Xinyang,Silk,Road,Machinery,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-17-2025 | 0.49 $* | 0.58 $* |

| Aug-17-2025 | 0.34 $* | 0.47 $* |

| Jul-17-2025 | 0.14 $* | 0.49 $* |

| Jun-17-2025 | 0.67 $* | 0.6 $* |

| May-17-2025 | 0.36 $* | 0.92 $* |

| Apr-17-2025 | 0.80 $* | 0.14 $* |

| Mar-17-2025 | 0.59 $* | 0.28 $* |

| Feb-17-2025 | 0.22 $* | 0.32 $* |

| Jan-17-2025 | 0.59 $* | 0.66 $* |

Характеристики

factory supply Biomass gasifier/gasification system|biomass gasifier stove

contact:sunny

whatsapp/mobile:008618737317087

skype:sunnymachinerysd

wechat:18737317087

Different raw materials can be used for this gasifier system.like below:

Introduction for our biomass gasifier

Our Biomass gasifier adopts downdraft fluidized bed technology, turn various of biomass material into combustible gas, then remove the dust, cooling, remove the tar, at last get high grade energy from low grade energy.

This technology not only confirms the biomass gasifier gas work continuously, but also improve the heat value of the combustible gas, reduce the tar content.

we have different models as below for your different choose!

The occurrence of biomass fuel gas

Biomass material get into the gasifier reactor from the top of the gasifier,then it will be dryed and heat, then along with the temperature increment, its volatile matter will be separated out and pyrolysis under high temperature, after pyrolysis the gas and carbon will react with supply air in the oxidation zone, then generate the CO and steam, the heat will use for remain dry area, pyrolysis and the heat absorption reaction in the reducing zone. The gas which generated from burning will go through high temperature carbon reduction zone, eact with carbon layer(C+CO2=2CO,C+HO2=H2+CO), become CO,H2,CH4,CmHn, etc.combustible gas. The tar under oxidation and decomposition. This technology improves the heat value of the gas and also reduces the tar.

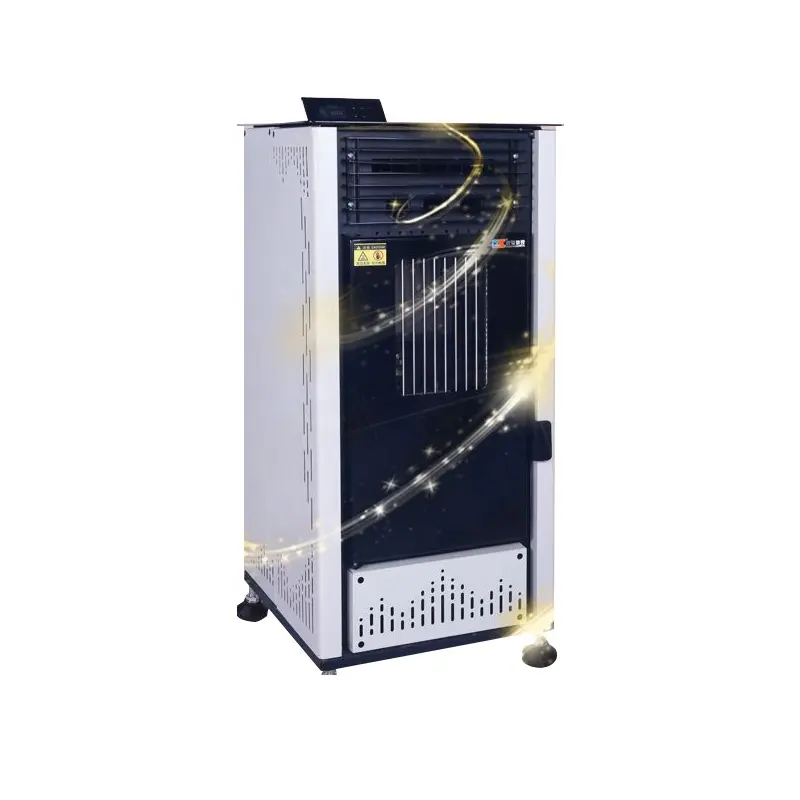

Model SRQ-10 image show:

Model SLQ-20 image show:

Model SRQ-30A image show:

Model SRQ-100B plant image show:

Biomass material

Suitable to all kinds of biomass material. Requirements for material:(1)Humidity of the raw material<20%,(2)Raw material size <20mm.To parts of material which cannot reach the requirement, it needs to crush and dry.

Biomass fuel gas composition

H2—12.3% CO—22.5% CH4—2.3% CO2—12.5% N2—48.8% O2 1.4% CH—0.2%.

(equipped with power generation to make the electricity power)