Непрерывная переработка дизельного топлива нефтеперерабатывающий завод от отработанного моторного

- Категория: Фильтр для машинного масла >>>

- Поставщик: Chongqing,Tong,Rui,Filtration,Equipment,Manufacturing,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-19-2025 | 0.8 $* | 0.64 $* |

| Aug-19-2025 | 0.79 $* | 0.64 $* |

| Jul-19-2025 | 0.52 $* | 0.9 $* |

| Jun-19-2025 | 0.23 $* | 0.0 $* |

| May-19-2025 | 0.31 $* | 0.78 $* |

| Apr-19-2025 | 0.46 $* | 0.84 $* |

| Mar-19-2025 | 0.14 $* | 0.93 $* |

| Feb-19-2025 | 0.39 $* | 0.61 $* |

| Jan-19-2025 | 0.91 $* | 0.74 $* |

Характеристики

Continuous Diesel Fuel Oil Recycling Refinery From Waste Engine Oil

Application:

DDR waste oil distillation plant can be applicable to all kinds of different feedstock ,typically as used engine oil,heavy

fuel oil ,tire pyrolysis oil ,hydraulic oil,gear oil,transmission oil etc. to convert those used lube oil into higt quality diesel fuel oil, heavy oil as well as gasoil and asphalt.

| Item | DDR-mini | DDR-1 | DDR-2 | DDR-3 | DDR-4 | DDR-5 | DDR-6 | DDR-7 |

| working capcity | 500L/D | 100L/H | 200L/H | 300L/H | 400L/H | 500L/H | 800L/H | 1000L/H |

| average power | 40KWH | 55KWH | 65KWH | 80KWH | 100KWH | 110KWH | 150KWH | 200KWH |

| voltage | 110V/220V/380V | |||||||

Flow chat(electric heating and burner heating system):

1 withoutsmoke and bad smell in the whole process,protect the enviroment

2) safty,the high temperature is more than 400 degree, but the temperature will be decreased quaickly due to the 3 stages water circulate condenser,be sure all machine is safe

3) good recycled oil quality which can be reused directly

4) recovery rate is more than 90%

5) burner heating method will guarantee safe, keep cooking and enhance heat efficiency

6) particular heating system, it will produce gas when oil is heated to 150 degree, and those gas will be can be sucked to the furnace for burning.this heating system will protect the machine and extend the life-span

7)Dust chamber system in chimney,there are double water spray nozzels to clean the dust,be sure the drain out dust up to international standard.

Particular for Used engine oil recovery machine for diesel oil :

1.why are most of our products with higher price than our competitors?

mature technologies and skillful workmanship (we control every single manufacturing process and make sure it will be done perfectly in our factory with the lowest cost with the best quality assurance) products quality guarantee and about 30 days free train(competitors cant spend much time in you factory,stay long you will find many problems about their machine)

2.what is the byproduct out of waste oil distillation equipments,how do i dispose it?

the byproduct are usually composed by gas , water,oil sludge/residue.the gas is purified for emission or recycled as heating fuel; the water will be purified as cooling water ; and oil sludge can be used for burning or as material for making asphalt

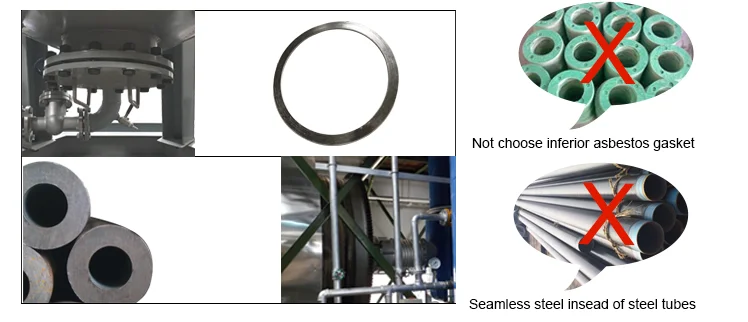

3.what are the consumables of this system?

the only consumable is catalyst which dosage as 1-1.5%. there is 1.5KGS of catalyst needed for processing 1 MT of waste oil

4.why dont we use continue system?

we test many times between continue and batch system,proved that batch system is best way,it is very dangerous to control under high temperature,almost we know distillation kettle temperature will arrive 400 degree,the no one can operate 24hours for you when they demo for you,once discharge with leakage,will fire or explode.

We provide many free services:

If you'd like we can provide overseas service Maintenance and replacement service, when it is necessary tracking service for products for 12 months, lifetime service lifetime technical assistant service. old customer has more discount, or the customer introduce others to us, which has more discount.