60 станций пресс-форм машина для изготовления тапочек и сандалий литья полиуретановой стельки

- Категория: Станки для обуви >>>

- Поставщик: Foshan,Luzhou,Pu,Machinery,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-19-2025 | 47600.38 $* | 49980.8 $* |

| Aug-19-2025 | 47200.12 $* | 49560.49 $* |

| Jul-19-2025 | 39600.60 $* | 41580.72 $* |

| Jun-19-2025 | 46400.4 $* | 48720.63 $* |

| May-19-2025 | 40400.4 $* | 42420.81 $* |

| Apr-19-2025 | 45600.62 $* | 47880.48 $* |

| Mar-19-2025 | 45200.54 $* | 47460.69 $* |

| Feb-19-2025 | 44800.95 $* | 47040.55 $* |

| Jan-19-2025 | 44400.98 $* | 46620.42 $* |

Характеристики

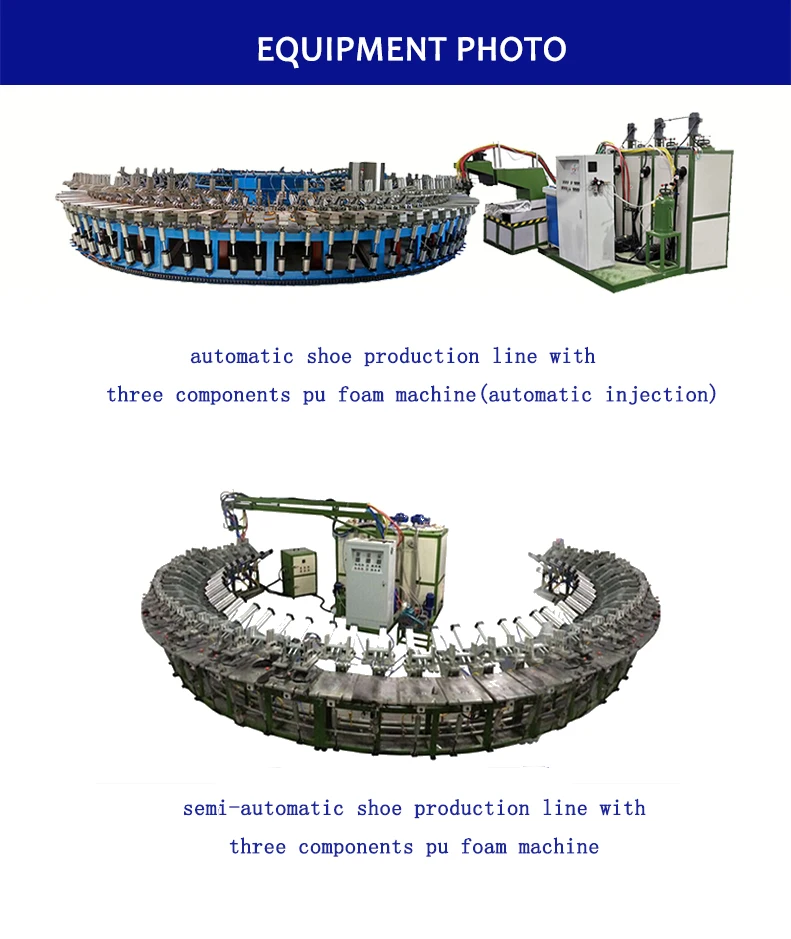

mold stations slipper and sandals making machine pu shoe sole injection banana type machine polyurethane insole foam machine

Product Application

This equipment is used to produce polyurethane insoles, outsoles, high heels, leather shoes, casual shoes, safety shoes, travel shoes,slippers, sandals, flip flops and other all kinds of polyurethane shoes.

Product Component

This equipment includes one three components low pressure pu foam machine and one automatic banana-type production line. According to the client's production capacity, the production line has 24, 36, 60, 80,100,

120 or other mold stations for choose.

![640640.jpg]() Why choose it:

Why choose it:

1. Most of the components are imported, like the metering pump and electrical components, greatly enhancing equipment running reliability and service life;

2. The moulds can be opened and closed automatically by the pneumatic system which can save the labor cost and around 2~4 people are required for the production only.

3. The molds are heated by circulating water heating system, it can save 3/2 electricity compared with the traditional manual machine, it also makes the temperature of the molds stabler.

4. the injection can be or can not be robotic control, which is customized for the client.

Why choose it:

Why choose it: