Коммерческий Завод цена свежий перец/имбирь/красный чили шлифовальный станок/специй

- Категория: Spice & Sauce Machines >>>

- Поставщик: Zhengzhou,Longer,Machinery,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-15-2025 | 0.50 $* | 0.40 $* |

| Aug-15-2025 | 0.22 $* | 0.35 $* |

| Jul-15-2025 | 0.53 $* | 0.25 $* |

| Jun-15-2025 | 0.92 $* | 0.94 $* |

| May-15-2025 | 0.58 $* | 0.80 $* |

| Apr-15-2025 | 0.41 $* | 0.87 $* |

| Mar-15-2025 | 0.26 $* | 0.70 $* |

| Feb-15-2025 | 0.78 $* | 0.57 $* |

| Jan-15-2025 | 0.93 $* | 0.20 $* |

Характеристики

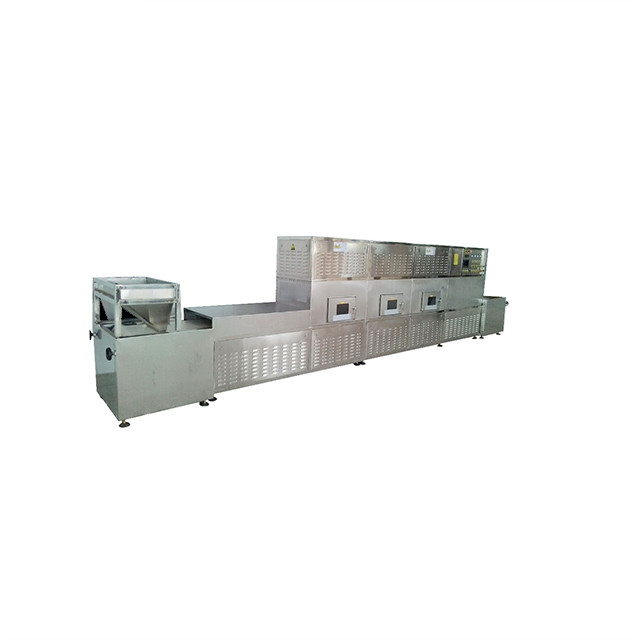

Factory Price Fresh Pepper/Ginger/Red Chilli Grinding Machine/Spice Grinder

Email: maggie @longerinc.com Whatsapp/Tel/ Wechat: 0086 185 6993 3368

Introduction

The peanut butter grinding machine is determined by the geometry, different rotor rotating in high speed under the relative motion, obtained by shearing, crushing, grinding and high frequency vibration. The crushing chamber is provided with three grinding zone, a grade for coarse grinding, fine grinding area as two level, three level for the attritor area, through adjusting the stator and rotor, can effectively achieve the required a superfine crushing effect (or cycle). This machine has the characteristics of compact structure, smooth running, low noise, corrosion resistant, easy cleaning, convenient repair. Is currently the most ideal equipment in the wet ground.

Application range of coffee,cocoa bean grinding machine:

1, the food industry: aloe, pollen, pineapple, hawthorn, carrot, juice, fruit juice, jam, fruit juice beverage, ice cream, food stuffing, red bean paste, coconut, lotus seed paste, cream, corn, bean paste, soy milk, peanut milk, peanut butter, sesame, malt flavor, dairy products, beverage,, chicken, seasoning, emulsifying pigskin, pet food

2, the chemical industry: paint, pigment, dye, paint, lubricating oil, grease, asphalt emulsion adhesive, etc.;

3, daily chemical industry: toothpaste, detergent, shampoo, shoe polish, cosmetics;

4, the pharmaceutical industry: all kinds of syrup, nutrition, medicine, pharmacy paste, biological products, health products, cod-liver oil, pollen, royal jelly, vaccine, ointment, oral liquid, injection, intravenous fluid, emulsion and so on;

5, the construction industry: all kinds of internal and external wall coating, waterproof anti-corrosion coating etc.

Technical Parameters

| Model | fineness | Capacity | Power | Dimension | Weight |

| LG-JMS-50 | 2-50um | 0.005-0.03t/h | 1.1/1.5kw | 530*260*580mm | 70kg |

| LG-JMS-80 | 0.07-0.5t/h | 4kw | 680*380*930mm | 210kg | |

| LG-JMS-110 | 0.3-1.2t/h | 7.5kw | 750*450*1000mm | 280kg | |

| LG-JMS-130 | 0.4-2.0t/h | 11/15kw | 990*450*1100mm | 400kg | |

| LG-JMS-180 | 0.8-6.0t/h | 18.5/22kw | 1000*480*1150mm | 450kg | |

| LG-JMS-240 | 4.0-12t/h | 37/45kw | 1330*650*1300mm | 1000kg | |

| LG-JMS-300 | 6.0-25t/h | 75/90kw | 1450*630*1420mm | 1600kg |

Q1. Which Parts can be changed 304 stainless steel?

A1: The hopper, discharge part and outsourcing part.

Q2. what is the material?

A2: Overall frame is carbon steel , outsourced is 202 stainless steel, stator is 420.

Q3. What is the voltage?

A3: The equipment is powered by three-phase power. Only models below LGJMS-80 can be changed to single-phase power; all types of equipment can change voltage and frequency.

Q4. Can I change the material of the stator and rotor?

A4: The material texture is soft. If the acid content is high, the 304 material can be used. It is generally not recommended to change the rotor material.

Q5. How is the discharge temperature?

A5: When grinding nuts, beans, long-term work monomer colloid milling temperature is 70-80 degrees Celsius, double colloid milling temperature is 100 degrees Celsius.

Q6. How to clean the machine?

A6: Clean the machine with water, dry it with a high-pressure air gun, keep it dry in a dry place, check the machine regularly and apply oil on the machine.

Q7. How to grind repeatedly?

A7: The colloid mill grinding nozzle can be changed to the circulating return pipe. The circulating return pipe is provided with a three-way valve. It can be discharged or cycled as needed. All models can be changed. The 80 and 110 return pipes are 25mm in diameter, 130/. 180 return pipe diameter 32mm.

Q8. How often to replace the fixed rotor?

A8: The nut material is generally grind 100-200T, the rotor must be replaced, for other materials, according to the hardness of the material and equipment using frequency.

Q9. How to use the cooling nozzles?

A9: The machine should be used cooling nozzles first, then start to grind material.

Zhengzhou Longer Machinery Co.,Ltd. founded in the year of 2010, is located in Zhengzhou City, Henan Province in China. We mainly engaged in producing all kinds of Frying Machines, Potato Chips Production Line and other Food Processing Machines.

Our company has many years' export experience in Machinery. We have outstanding quality control personnel as well as Trained Techinical Workers, and we have established a strong quality guarantee system. Our products are sold very well and are introduced to South-East Asia, Eastern Europe and Africa.

1.We always use standard export wooden packing, carton box.

2.You can choose express, by air, by train or by sea. Always we will give our best recommend based on our experience.

3.We cooperate with China best shipping company to get best price and fast delivery.

4.You will get full feedback when your machine is on the way.