RTV2 силиконовая резина для полиуретановых смол

- Категория: Силиконовая резина >>>

- Поставщик: Dongguan,Guochuang,Organic,Silicone,Material,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-16-2025 | 0.11 $* | 0.78 $* |

| Aug-16-2025 | 0.20 $* | 0.96 $* |

| Jul-16-2025 | 0.88 $* | 0.84 $* |

| Jun-16-2025 | 0.25 $* | 0.17 $* |

| May-16-2025 | 0.59 $* | 0.55 $* |

| Apr-16-2025 | 0.49 $* | 0.21 $* |

| Mar-16-2025 | 0.37 $* | 0.17 $* |

| Feb-16-2025 | 0.49 $* | 0.85 $* |

| Jan-16-2025 | 0.61 $* | 0.40 $* |

Характеристики

RTV2 silicone rubber for polyurethane resins for casting

1. Description of RTV2 silicone rubber for polyurethane resins for casting

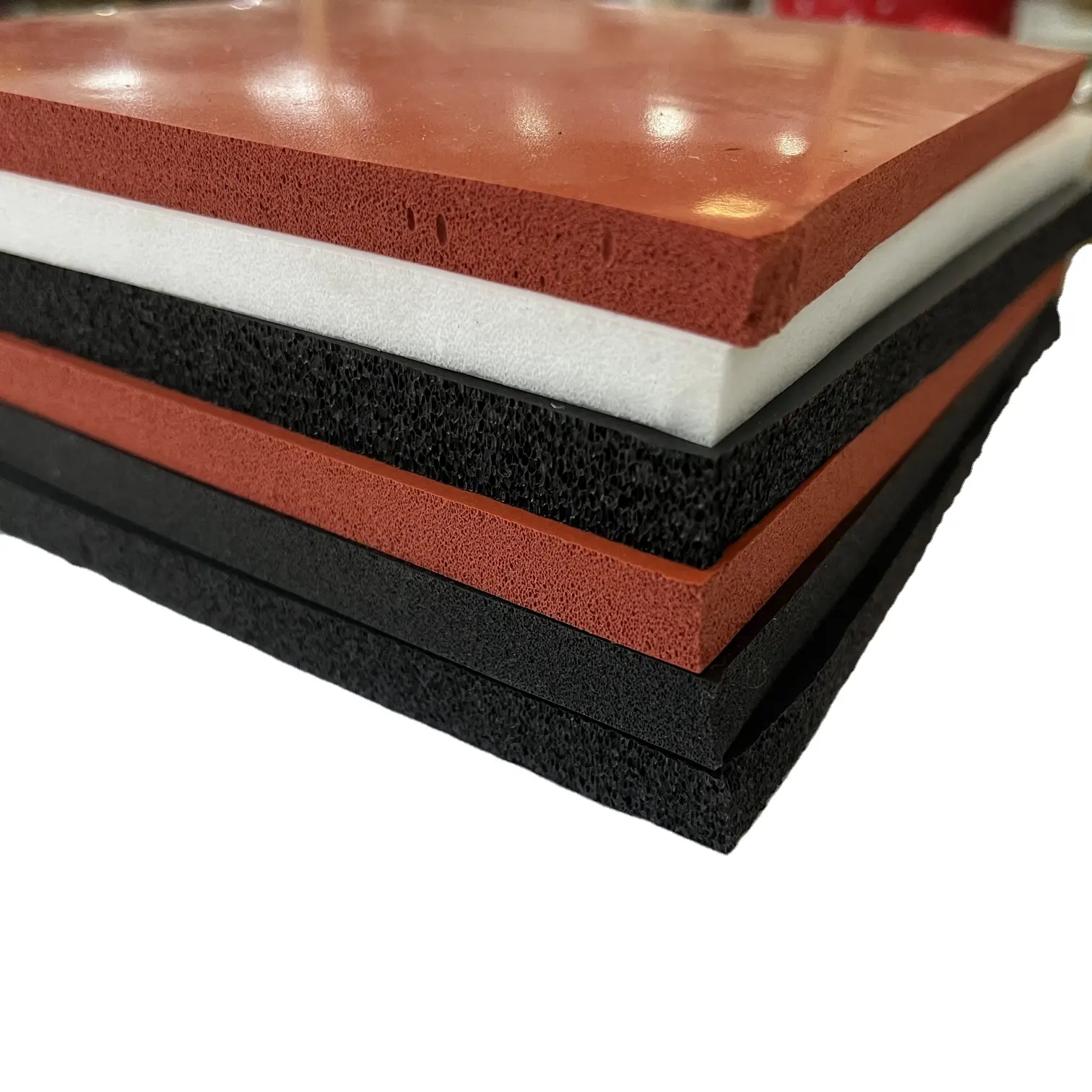

It is a kind of room temperature vulcanized silicone rubber in condensation type. It's generally named as two part silicone rubber, Part A is a flowable liquid, part B is the curing agent or catalyst. It's mainly used for all mold making with different size and pattern.

2. Characteristics of RTV2 silicone rubber for polyurethane resins for casting

1. Suitable for both pouring molding and brushing molding

2. Strong tear strength and tensile strength

3. Easily release air to avoid bubbles

4. excellent non-stick effect

5. Various hardness from 5 to 40 shore A

6. Excellent flexibility, easy to demould.

7. High temperature resistance, high duplication times and repeated use

8. Good cut-growth resistance

3. Application of RTV2 silicone rubber for polyurethane resins for casting

two component liquid silicone making mold for stone figures molding, which with good tensile strength as well as high duplication times ,so it is perfect for making mold in statue and figures industries ,such as Stone figurine ,ceramic statues,polyurethane statuary, ceramic statues,polyurethane animals,Buddha, plaster ceiling, artificial stone, GRC home decorations etc.while,it also application for making mold for Resin and poly resin crafts, Lighting ornaments, candles crafts, statue Buddha, relief, artifacts copied, Animals and plants sculpture.

4. Datasheet of RTV2 silicone rubber for polyurethane resins for casting

5. Using instructions of RTV2 silicone for polyurethane resins for casting

Step 1: prepare the original molds

Prepare an perfect mold modle and clean it totally(the release agent can be detergent, soapy water and Vaseline)before operation .Take 100g silicone material and 2~5g curing agent strictly and mix them evenly.

*Notes:Make sure the toys and operation tool cleaned up totally to avoid uncure problem .

Step 2: Vacuum pumping

Without exception, this step takes less than 10 minutes.(normally is 5munites) Otherwise, it will cause cross linking reaction, and no more further steps will be available.

Step 3: Pouring casting or Brushing operation

1. For simple pattern products we suggest use pouring operation way, which will be very easy to operate and demould. Pourable silicone require light viscosity which will be easy to flow smoothly and easy to de-air . (mold with fine and precision patterns with low hardness.)

2.For delicate pattern products we suggest use brushing operation way.which can copy the pattern exactly .brushing way require high viscosity which won’t be easy to flow away and easy to brush(large size molds with high hardness)

3.The amount of the curing agent can be adjusted according to the actual requirements of the customer. If molds requiring fast drying and demould, more curing agent is needed; contrarily, if molds requiring slower drying and demould, less curing agent is needed.but we don’t suggest to add silicone oil avoid oil problem.

Step 4:Demoulding:

After 35 hours later, can demould the silicone mold, it's will be better for molf to demould after 24 hours.

Notes:The curing temperature and curing time can be adjustable according to the operation conditions.

Package

25KG/drum vacuum packing for part A +1kg/ bottle catalyst for part B

200KG/drum packing for part A +1kg/ bottle catalyst for part B

Shelf life and transportation

1. Twelve(12) months when stored at 25℃ in tightly closed original packages.

2. The liquid silicone rubber is non- dangerous product (not inflammable and explosive), which could be transported as general chemicals.

Factory price: best quality guaranteed.

Free sample for testing.

Superior service :we offer perfect both pre-sales and after-sales service.

Enough production capacity and timely delivery.

Strict QC control: 100% QC inspection for the products at least 3 times before shipping out.

OEM service: a range of designs available, clients' designs are welcome and will be treated confidentially.

Prompt shipment with professional documents.

Offering professional technical support.

Dongguan Guochuang Organic Silicone Material Co., Ltd. established in 2003, is a Science and technology corporation which is engaged in production, R & D, and sales of silicone rubber and silicone mold. We sets up HongKong GuoChuang silicone technology Co.,Ltd., other affiliated enterprises in 2015.

We have passed ISO9001:2008 Quality Management System. We have five main groups of people: R & D team which is rich in theoretical knowledge and work experience; sales team who are proficient in several languages and with high level of business & after-sale service;With such a team, we promote our silicone rubber to Southeast Asia, Europe, the Middle East , the America and etc, and our silicone rubber is well-received by the customers from more than 98 countries and regions.

We believed that we can really provide you the high quality and competitive price , and even the technical support and perfect after-sales service.We will offer the best solutions to promote both of our business and make the win-win situations.Thanks !

1. Why will the silicone mold be reused only for a few times?

It can be due to the following reasons:

a. Adding too much silicone oil in to silicon rubber. Silicon oil is an additive which can destroy the molecular weight of silicone rubber and reduce the tension and tear strength.

b. Using the silicon rubber with a high hardness to make molds for small sized products with delicate and intricate designs or the silicon rubber with a low hardness to makes molds for large sized products with simple designs.

(Notes: we should choose the silicon rubber specifically according to the requirements of our products to avoid this problem.)

2. Why does the silicone mold appear to dry outside but wet inside?

Because molding silicone rubber is a kind of condensation silicone rubber, which get solidified after absorbing moisture from the air. In order to provide a significant shelf-life for the silicon rubber, we will dry out the water in the silicon rubber.

Solution: Add 0.1% water into the silicon rubber and Stir over a low speed briefly when you use it.

3. Why is the silicon mold oily?

The molding silicone rubber itself doesn’t contain any oil, so it won’t be oily. If the mold is oily, it may be because you add the compound silicone oil( the compound of silicon oil and white oil). The white oil is not silicon oil but a kind of petrochemicals.

(1) With us your money in safe, your business in safe.

(2) Free sample for testing.

(3) Competitive price.

(4) Strict Q/C (quality of control) management system.

(5) Enough production capacity and timely delivery.

(6) We support customized package and product.

(7) Prompt shipment with professional documents.

(8) Offering professional technical support.

(9) We can make confidentiality agreement with our customs.

(10) We will be here whenever you need.