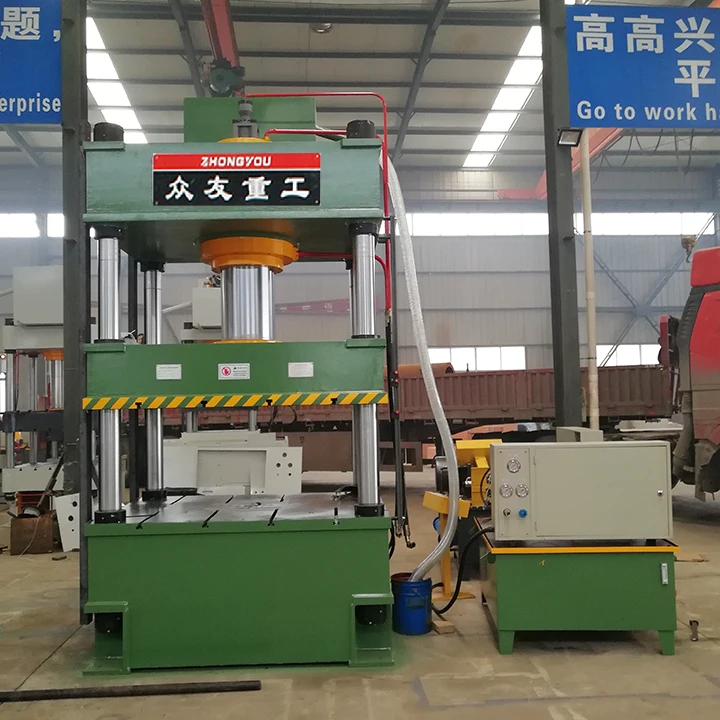

Гидравлический тепловой пресс машина для композитов SMC Панели резервуара

- Категория: Другие гибочные станки >>>

- Поставщик: Zhongyou,Heavy,Industry,Machinery,Equipment,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-17-2025 | 41650.41 $* | 43733.5 $* |

| Aug-17-2025 | 41300.14 $* | 43365.34 $* |

| Jul-17-2025 | 34650.83 $* | 36383.68 $* |

| Jun-17-2025 | 40600.15 $* | 42630.4 $* |

| May-17-2025 | 35350.58 $* | 37118.94 $* |

| Apr-17-2025 | 39900.21 $* | 41895.5 $* |

| Mar-17-2025 | 39550.10 $* | 41528.42 $* |

| Feb-17-2025 | 39200.41 $* | 41160.74 $* |

| Jan-17-2025 | 38850.1 $* | 40793.76 $* |

Характеристики

heat press machine for composites SMC water tank panels

YQ32 series SMC material forming machine is one type of hydraulic press machine.It is for flanging and bending of stainless steel utensils.It is very important for industry daily.

Advantage of our machine:

1. The four-column structure is economical and practical.

2. The liquid control adopts an integrated cartridge valve integrated system, which reduces the leakage point, ensures reliable operation and long service life.

3. The machine can realize two forming processes of constant pressure and fixed stroke, and has adjustable pressure delay time.

4. The working pressure and stroke can be adjusted within the specified range.

5. The machine adopts centralized control of buttons and has three operation modes: adjustment, manual and semi-automatic.

1.The main oil cylinder of machine is piston cylinder, nominal pressure is realized by the main cylinder, and oil cylinder connected with the slider. Oil cylinder is installed on the frame, through the oil cylinder lock lock, the piston rod surface of wear-resisting, oil cylinder are chooses import packing seal, long service life, reliable sealing performance.

2.Pillar of 45 # steel material refined processed, after cutting, grinding, hardening, chrome plating and other working procedures, enhance the pillar surface hardness and wear resistance, to ensure that the column surface strain. Between slide block and columns with column guide bush, rely on the pillar as the guidance to do up and down.

3.The hydraulic integrated control valves:Integrated hydraulic control valve with domestic two-way cartridge valve centralized control, with regulating the reversing pressure unloading support fast speed conversion overpressure protection function on the main cylinder inferior vena control block with secondary antiskid blocks falling device and relief valve, when the slider stops at any position, the device automatically shut down, to ensure the reliability and security of the sliding block; When its inferior vena closed due to valve piece of card to death, the bypass valve plays a role of oil discharge in a timely manner, to avoid safety accident.

4.The machine ejection cylinder as the piston cylinder, ejection cylinder installed in the workbench. Mother and workbench fixed, by big lock (DingGang design should consider convenient dust and dust) on the surface of the piston rod wear processing, cylinder selects the import of seal sealing, long service life, reliable sealing performance

5.Hydraulic system:The oil hydraulic system is to produce and distribute work unit, and make the host various action for steel weldments, tank adopts closed structure equipped with a filter in the cabinet, box wall open hole is for cleaning tank; Equipped with level gauge, fuel tank is equipped with the integrated body above pump power plant such as the machine using the main hydraulic components in the hydraulic system

6.In the electric control cabinet is equipped with lighting and ventilation equipment, electrical control cabinet with good sealing, can effectively prevent dust intrusion

Control unit: adopting PLC programmable controller control

Operation mode: both inching semi-automatic operation mode

Working style: constant pressure repression and the limit of pressing one of two ways

NOTE:ALL PARAMETERS COULD BE CUSTOMIZED ACCORDING TO REQUIREMENTS!

The products are widely used in the deep drawing, bending, flanging, cold extrusion, punching and other processes of metal materials, and are also suitable for the correction, press-fit, powder products, abrasive products and plastic products, and SMC compression molding of insulating materials. We also can provide molds of manhole cover

Zhongyou Heavy Industry Machinery Equipment Co.,Ltd With an experience of many years, we are engaged in manufacturing and supplying a wide range of Four-Column Hydraulic Press Machine. This is a machine tool for bending sheet and plate material. In order to ensure its high functionality, this is tested by our quality inspectors on numerous parameters. Further, this Four-Column deep drawing Hydraulic Press Machine is used to prepare all kinds of products.

our team

1:How can I choose the most suitable machines ?

A: Please tell me your specifications ,we can choose the best model for you , or you can choose the exact model .You can also send us the products drawing ,we will choose the most suitable machines for you .

2: What's your main products of your company?

A: We specialized in hydraulic press Machine .we mainly produces various hydraulic presses forging press and auto maintenance equipment with advanced technology and equipment.

3: Where is your factory located? How can I visit there?

A : Our factory is located in Tengzhou City ,Shandong Province,277500 China. You are warmly welcomed to visit us.

4. What is your trade terms?

A : FOB, CFR and CIF all acceptable.

5: What's the Payment Terms ?

A : T/T ,30% initial payment when order ,70% balance payment before shipment ;Irrevocable LC at sight .