Гранулы

- Категория: Прочие продукты энергетической отрасли >>>

- Поставщик: Hubei,Everflon,Polymer,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-17-2025 | 0.39 $* | 0.1 $* |

| Aug-17-2025 | 0.54 $* | 0.71 $* |

| Jul-17-2025 | 0.91 $* | 0.2 $* |

| Jun-17-2025 | 0.69 $* | 0.84 $* |

| May-17-2025 | 0.71 $* | 0.92 $* |

| Apr-17-2025 | 0.2 $* | 0.23 $* |

| Mar-17-2025 | 0.55 $* | 0.96 $* |

| Feb-17-2025 | 0.97 $* | 0.59 $* |

| Jan-17-2025 | 0.9 $* | 0.6 $* |

Характеристики

Products Information

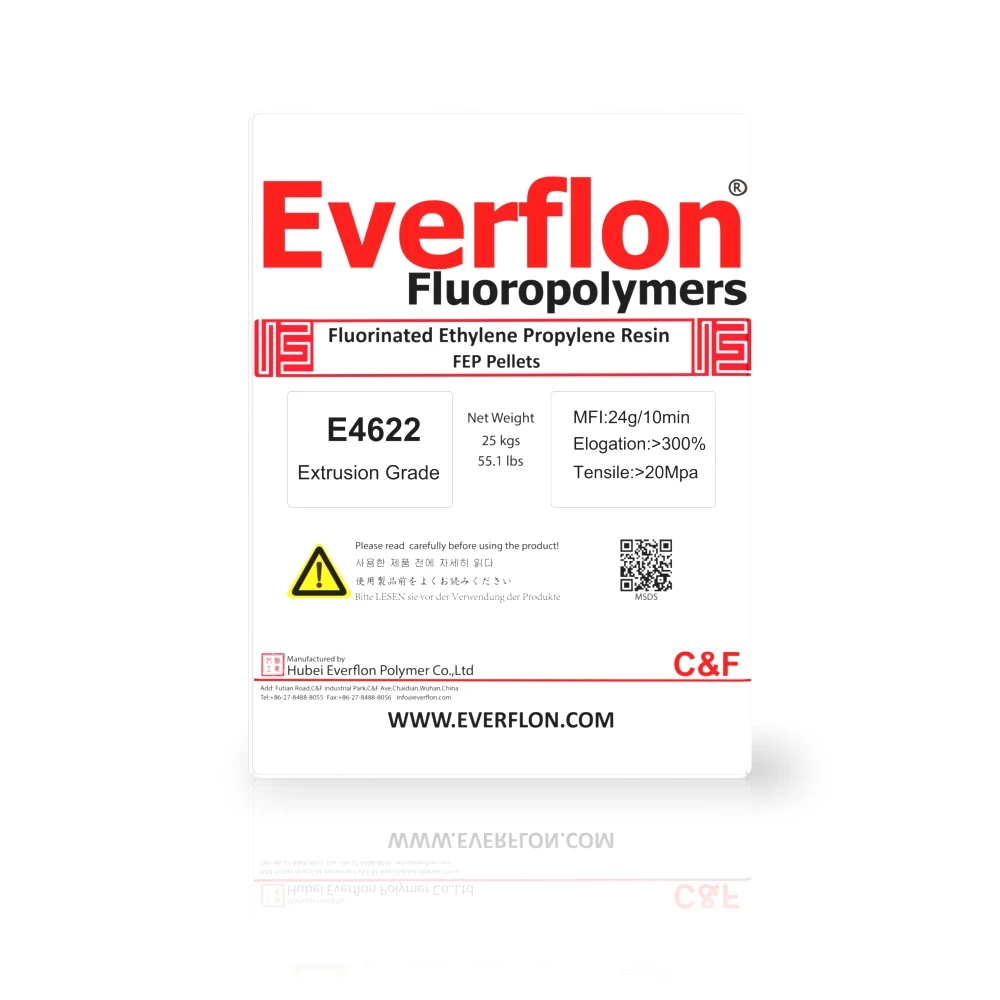

Everflon Fluoropolymer FEP Resin

Everflon® FEP resin is a melt-processible copolymer of tetrafluoroethylene and hexafluoropropylene, without additives, that meets the requirements of ASTM D 2116

Everflon™ FEP fluoroplastics are processed by conventional melt extrusion techniques and by injection, compression, transfer and blow molding processes. Everflon™ FEP fluoroplastics are ideal for wire coating and molding a wide variety of end use articles and components.

Everflon™ FEP offers an excellent combination of properties characteristic of all fluoroplastics; a wide service temperature range, exceptional dielectric and electrical properties, low coefficient of friction, low flammability and chemical resistance.

Everflon™ FEP has a service temperature range, up to 200°C (392°F).

While Everflon™ FEP can be fabricated into solid shapes and molded articles it is best known as an industry leading product line in the wire and cable industry where it is used for wire coating and cable jacket fabrication. Everflon™ FEP offers wire and cable OEMs a high performance fluoroplastic material with excellent electrical properties, ease of processing and consistent performance.

The Everflon™ FEP product line is one the broadest in the industry. With Melt Flow Rates (MFR) from 3 to 30, and a wide range of application specific grades, Everflon™ FEP is uniquely positioned to offer exceptional performance in both general purpose and high speed wire and cable constructions.

The Properties of Everflon Fluoropolymers

Property | Unit | Everflon FEP | ||

Processing | ||||

Melt Flow Rate | g/10min 372℃ | 1-30 | ||

Melt Point | ℃ | 260 | ||

Density 23℃ | g/cm3 | 2.15 | ||

Mechanical | ||||

Tensile strength, | MPa 23 °C (74 °F) | >30 | ||

Elongation | 23 °C (74 °F) | >300 | ||

Hardness | Shore Durometer | D56 | ||

Electrical | ||||

Dielectric constant | 103HZ-106HZ | 1.9-2.1 | ||

Dielectric loss angle tangent value | 103HZ | 3*10-4 | ||

106HZ | 5*10-4 | |||

Surface resistivity | 1015/Ω | >1-10 | ||

Arc resistance | Sec | 165 | ||

Thermal | ||||

Melt viscosity300℃(572°F) | Pa.s | 103-105 | ||

Glass state temperature | ℃/°F | -90(-130) | ||

Application temperature | Min℃/°F | -195(-319) | ||

Max℃/°F | 200(392) | |||

Decomposition temperature | ℃/°F | >390(734) | ||

Thermal conductivity | W/m•K, | 0.26 | ||

Zero strength temperature | ℃ | 265-320 | ||

Heating ageing | 200℃ | No degradation and No cross-linking for 1000 hours | ||

Application

Wire insulation, cable jacketing, extruded tubing, molded shapes and other end use components requiring a high performance fluoroplastic material.

Processing

Everflon™ FEP fluoroplastic resin can be processed by conventional melt extrusion, and by injection, compression, and blow molding processes. For smooth feeding to extrusion equipment, it is supplied in 3 mm (0.12 in) pellets.

The extruders and molding machines used for Everflon™ FEP should be constructed of high nickel alloy corrosion-resistant materials and be capable of operating at temperatures up to 400 °C (750 °F).

Packing & Delivery

Storage&Handing

Everflon FEP resins are not affected by storage time. Ambient storage conditions should be designed to avoid airborne contamination and water condensation on the resin when opening and emptying the packaging.

Package&Caution

Everflon® FEP is packaged in 25kg, single layer, plastic bags. For convenient shipment, orders of 1,000-kg pallets are

recommended.

The properties of Everflon® FEP resins are not affected by storage time. Ambient storage conditions should be designed to avoid airborne contamination and water condensation on the resin when opening and emptying the packaging.

Everflon FEP

Everflon's FEP

Everflon® FEP is a melt-processible fluoroplastic resin available in pellet form. It is a copolymer of tetrafluoroethylene(TFE) and hexafluoropropylene(HFP), without additives, has a lower melt viscosity than PTFE and can be processed like other thermoplastic resins by the melt flow processes of extrusion, transfer, injection and compression molding. Because the bonding energy between its carbon and fluorine atoms is so high, and the molecule is completely filled with fluorine atoms, Everflon FEP fluorocarbon polymer has excellent thermal, electrical, and chemical stability.

AN EXCELLENT ELECTRICAL INSULATOR

A low dielectric constant and dissipation factor exist along with high dielectric strength over a wide range of frequencies and

temperatures.

temperatures.

LOW FRICTION

Everflon FEP offers the lowest critical surface energy of any plastic material in addition to excellent water and oil repellency for non-stick and mold release applications.

HIGH TRANSPARENCY

Products prepared from Everflon FEP are transparent with good transmittance of both ultraviolet and visible wavelengths; the lowest refractive index of any plastic and characterized by very low light reflection

TOLERANT OF HIGH TEMPERATURES

Everflon FEP offers superior reliability and retention of its properties in a wide thermal range from cryogenic to high

temperature (-200°C to +200°C).

temperature (-200°C to +200°C).

FDA APPROVED & FOOD SAFE

This makes it an excellent choice for applications in food manufacturing and packaging, particularly since the material is food grade compliant and resistant to staining.

CHEMICALLY RESISTANT & INERT

Everflon FEP maintains its physical properties in extreme environments. It provides excellent chemical and permeation resistance including exposure to weathering, light, and moisture.

Visit US

About Everflon Fluoropolymers

Everflon® Fluoropolymer specializes in the production, development, and sales of high-performance fluoropolymer materials. It provides the most basic fluoropolymer raw materials for C&F Group's fluorochemicals. After years of research and development and production, it is currently PTFE, FEP,PFA,ETFE and PVDF materials, and can provide a variety of physical properties of dispersions, granules and powder to meet the needs of various processing applications such as spraying, extrusion, molding, injection molding.

Relying on the Group's Quality Assurance Department and Application Laboratory, Everflon® provides the highest quality and stable fluoroplastic raw materials to meet the high quality requirements of middle and high-end customers and reduce the quality of raw materials caused by production and processing. Problems such as rising costs and inefficiency have established extensive and stable cooperative relations with main-stream manufacturers at home and abroad.

Everflon Fluoropolymers Family

Похожие товары

Сушеные дрова в мешках из бука/дуба

EUR 40.00-70.00

Лучшие Сухие Дубовые Дрова из бука

US $70.00-$90.00