Машина для вытягивания профиля стекловолокна

- Категория: Other Plastic & Rubber Machinery >>>

- Поставщик: Huabin,General,Machinery,&,Equipment,Import,Export,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-15-2025 | 178500.2 $* | 187425.31 $* |

| Aug-15-2025 | 177000.41 $* | 185850.26 $* |

| Jul-15-2025 | 148500.43 $* | 155925.75 $* |

| Jun-15-2025 | 174000.72 $* | 182700.5 $* |

| May-15-2025 | 151500.76 $* | 159075.18 $* |

| Apr-15-2025 | 171000.34 $* | 179550.73 $* |

| Mar-15-2025 | 169500.33 $* | 177975.94 $* |

| Feb-15-2025 | 168000.25 $* | 176400.98 $* |

| Jan-15-2025 | 166500.71 $* | 174825.71 $* |

Характеристики

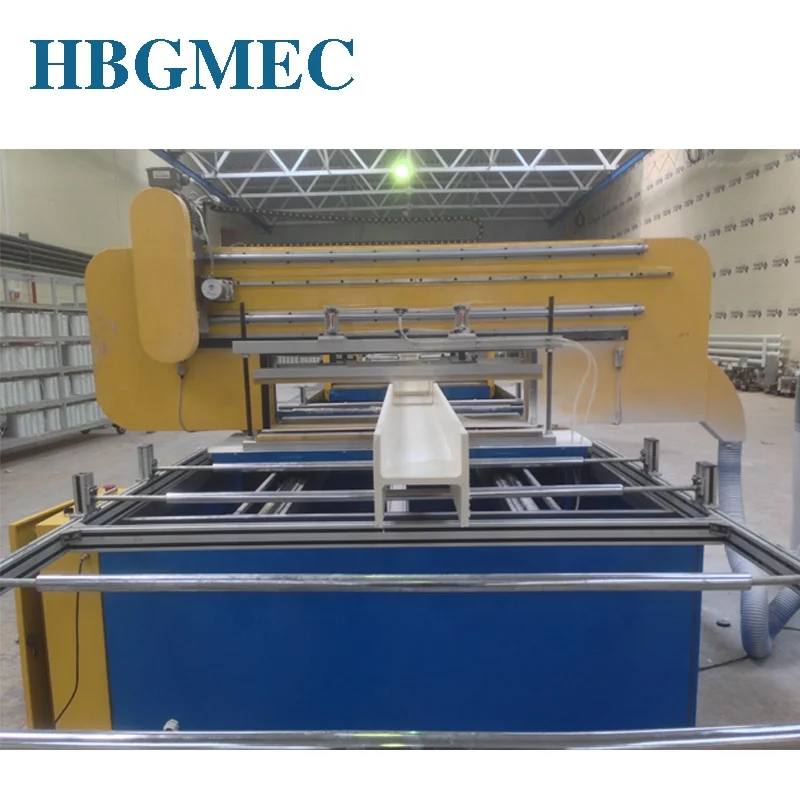

Hydraulic Pultrusion Machine for frp profile

Feature of pultrusion Equipment:

- Maximum Pulling force (Pressure range from 0 - 1885 PSI, 0 to 13 MPa)

- Maximum Clamping force (Pressure range from 0 - 1885 PSI, 0 to 13 MPa)

- The Pulling cylinder stroke: ranging from 17.7-19.7 inches, 450~500 mm

- The die is divided into 6 heating areas. Adjustable temperature, ranging from 0~392 - 10F (0~200 - 10C) and temperature can be automatically maintained at a constant level.

- The traction operation can be controlled either manually or automatic.

- Electric power for die heating: 18 to 24Kw

- Die platform dimensions: 43.3" x 31.5" (1100 x 800 mm) (Can be customized)

- Clamp pressures & maximum pulling pressures adjustable by operator.

- Hydraulic Pump manufactured by "YUKEN", Japan.

- "OMRON" PLC elements utilized in the control system.

- Solenoid direction valves manufactured in Switzerland.

- "SMC" seals used in cylinder sealing system.

- Speed regulator valve manufactured in Switzerland.

- Electrical heating module utilizes solid-state, contactless relay and the heating element is made of aluminum alloy.

- Touch Screen LCD display control system utilizing "OMRON" products

- Pultrusion timer included (intermittent pultrusion & automatic die purge).

- Availability of PLC software & code with commands (English) to allow additional functions to be modified.

- Hydraulic fluid tank sealed with a filtered breather.

- All return fluid (especially case drain lines from the hydraulic pumps) filtered prior to return to the hydraulic fluid tank.

- Temperature control module utilizes "OMRON" products.

- Thermostatically controlled oil cooler with electric fan to maintain hydraulic fluid at the correct operating temperature.

- Return line filter with replaceable cartridge in oil return line to the tank.

- Variable rate pistons with pressure and flow compensation controlled by the puller circuit.

- Separate pump for the clamping function (both pumps driven from the same electric motor

Похожие товары

Замена керамического электрода enercon corona

US $500.00-$7000

Машина для производства арматуры FRP с сертификатом CE/ISO

US $23800-$65800

Стандарт Ce, линия по производству капельного орошения

US $135000-$140000