Клетка для сбора пыли клетка

- Категория: Other Filter Supplies >>>

- Поставщик: Shandong,Aobo,Environmental,Protection,Technology,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-16-2025 | 0.96 $* | 0.29 $* |

| Aug-16-2025 | 0.61 $* | 0.39 $* |

| Jul-16-2025 | 0.96 $* | 0.46 $* |

| Jun-16-2025 | 0.58 $* | 0.27 $* |

| May-16-2025 | 0.6 $* | 0.95 $* |

| Apr-16-2025 | 0.66 $* | 0.58 $* |

| Mar-16-2025 | 0.87 $* | 0.68 $* |

| Feb-16-2025 | 0.14 $* | 0.82 $* |

| Jan-16-2025 | 0.21 $* | 0.83 $* |

Характеристики

FILTER CAGE

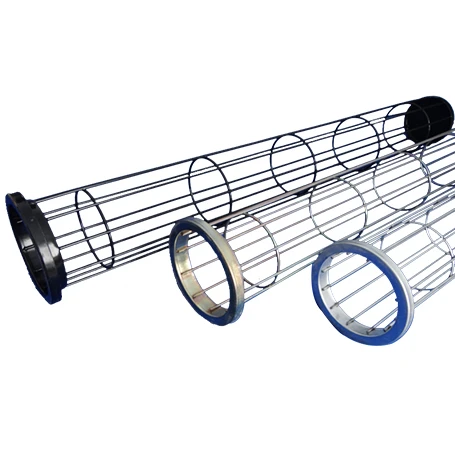

Shandong Aobo offers a full range of high quality supporting cages to complete its wide product portfolio. The supporting Cages are manufactured to give the best possible match with Filter Bags, thus granting a trouble free and long lasting operation to our customers. Shandong Aobo is the largest cage producing factory in the north China.

Filter Cages are available in a large variety of shapes, materials and finishing treatments; can be used in several industrial applications and under the most severe operating conditions. Supporting Cages are produced according to all the most common OEM designs or tailor-made to specific needs.

The supporting cages can be supplied with Venturis and other accessories as requested by the application.

Dimensions

o External diameter: from Ø100 to Ø190 mm

o Length for 1 part cages: from 500 to 7.000 mm

o Length for more than 1 part cages: up to 12.000 mm

o Diameters of longitudinal wires and ring wires: from Ø 2,5 to Ø 6 mm

o Different cage section shapes: from 4 to 24 wires

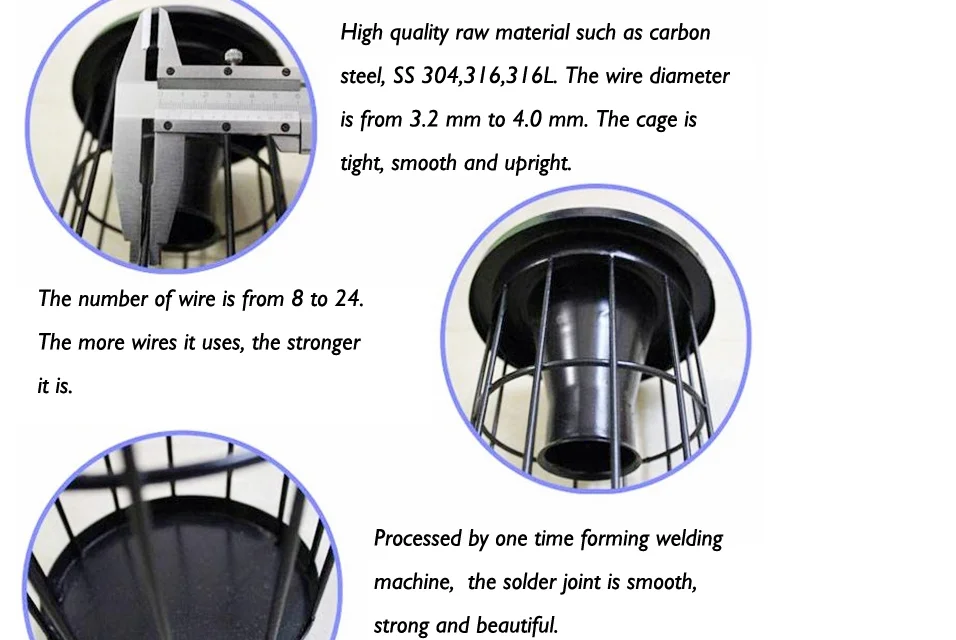

Materials

o Carbon steel

o Cataphoresis (Powder coated )Painting carbon steel

o Pre-galvanized carbon steel

o Stainless steel AISI 304, 316, 316L and other on request

Type of finishing

o Cataphoresis coating for high temperature and corrosion resistance

o Epoxy and polyester powder coated

o Pickling and Passivation (for stainless steel)

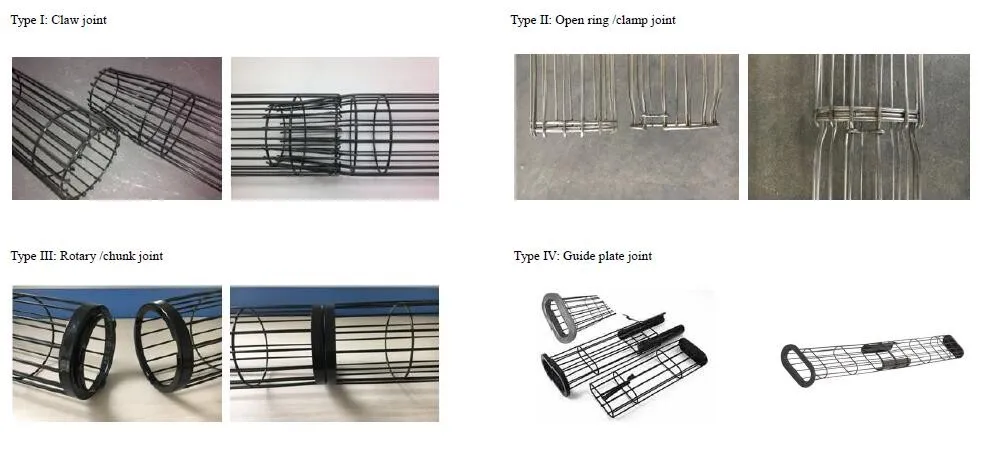

Junction/ Split

o Varieties of the splits

o Rotary /chunk joint

o Open ring /clamp joint

o Claw joint

o Guide plate joint

Venturi & collars

o Customized size and shape of the venturi

o Cage sleeve with shutters style

o Customized top and bottom collars

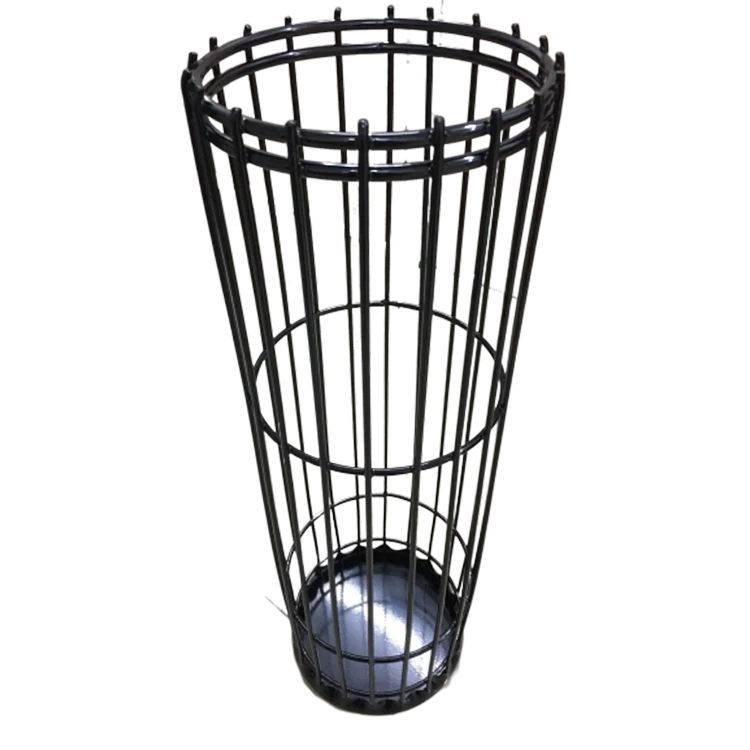

Shapes

o Round shapes

o Over shapes

Venturi nozzles

In order to ensure an effective regeneration of the filter bags, the supporting cages are equipped with Venturi nozzles. Their form and mounting position on the supporting cage depend on the design project and requirements of a dedusting system. Venturi nozzles can be made of steel, aluminum or plastic, depending on the working environment.

Top collars

Flat flanges, snap ring, with integrated Venturi, the detail size can be adapted according to customer demands.

Varieties of the splits / Interlocking / Junctions Support cages

Depending on the design of the dedusting system, its size, location and accessibility for the installer, supporting cages can be single-parted, two-parted, three-parted or, for untypical projects, also multi-parted. If there are several elements, they must be interlocked to ensure a stable support surface. The connecting elements are manufactured in such a way that the installation can proceed quickly and without problems. Below we present the most common and recommended connections.

Steel with cataphoresis (powder coated) Support cage

Cataphoresis is a modern method of pre-coating steel elements for corrosion protection.

Thanks to the phenomenon of electrophoresis (movement of charged particles to the electrical field lines), the water-soluble epoxy paint reaches places inaccessible to traditional methods of painting.

Colloidal particles are placed on an electrode over an electric field.

A further advantage of this processing is its high aesthetics and good ground for further covering methods such as powder coating or spray coating. Support cages pre-coated by cataphoresis have many years guarantee at working temperatures of up to 300oC.

Process:

1. Put the cage into oil removal pool for 15 min to remove the grease and oil which is on the cage surface.

2. Put the cage into cleaning pool to remove the oil remover which come from step1

3. Put the cage into rust remove pool to remove the metal oxide layer to strength adsorption force

4. Put the cage into phosphating pool to strength adhesion force

5. Put the cage into the big oven, and temperature is 100℃, and about 20~30 min, to remove the surface moisture

6. Put the cage into painting room, and Epoxy Silicone painting treatment, the thickness of painting is about 60μm~100μm

7. Put the cage into a big oven, firstly temperature is 220℃, about 120 min, after that, temperature is 200℃, about 30 min. Then natural cooling. The best efficiency of the thickness is about 60-70μm

Packaging, storage, transportation

The supporting cages offered by us are packaged professionally on special pallets, For Seaworthy Packaging (20GP, 40GP, 40HQ Containers)

o Each cage with plastic bag

o Each steel frame with forklift

o Each wood plated for the cage length less than 2.0meter or 2.5meter

Shandong Aobo Environmental Protection Technology Co., Ltd., as a member unit of China Non-Woven Association and a member of China Bag Dust Association, is situated in Wucheng Economic Development Zone of Dezhou City, which was titled as "Reaching in all directions". Our company has a beautiful surrounding environment and convenient transportation. We are only three hours' drive away from Beijing and one hour away from Jinan. Our factory covers an area of 200 acres with office buildings, research rooms, product exhibition halls, dust filtering material workshops, air filter material workshop, and hard cotton thermal insulation material workshops. Our company has a world-class non-woven production line introduced from Germany, a needle-punched hot-air hot-melt production line and Japanese exclusive electromagnetic sewing bonding filter bag production lines. Our company has a professional filter & purification scientific research room together with a professional after-sales service team.

Shandong Aobo offers a full range of high quality supporting cages to complete its wide product portfolio. The supporting Cages are manufactured to give the best possible match with Filter Bags, thus granting a trouble free and long lasting operation to our customers. Shandong Aobo is the largest cage producing factory in the north China.

Filter Cages are available in a large variety of shapes, materials and finishing treatments; can be used in several industrial applications and under the most severe operating conditions. Supporting Cages are produced according to all the most common OEM designs or tailor-made to specific needs.

The supporting cages can be supplied with Venturis and other accessories as requested by the application.

Bag Cage Install and Storage Requirements

• Before installing filter bags the tube sheet must be checked to ensure that it is clean, there are no sharp edges and there is no debris that could eventually fall into the filter bags

• The installation procedure is normally decided on site and is dependant upon the number of personnel being used and the available access. Normally it is wise to work compartment by compartment first fitting all the filter bags.

• The filter bags fitting is simple via a snap band, no tools are required. The filter bag is lowered into the corresponding tube sheet hole and the top seal is made by forming a kidney shape in the snap band top and then releasing this into the tube sheet hole. The groove in the filter bag should fit tightly into the tube sheet forming a seal.

• This is repeated until all the filter bags have been fitted.

• Before lowering the cages into the filter bags boards or heavy cardboard should be placed over the bags to protect the filter bags and prevent them being stepped on. If the bags are stepped on they can loose the seal and cause dust emissions at a later date.

• During the installation of the cages care should be taken not to damage or bend the cages. No damaged, badly bent or corroded cages should be fitted into the filter bags.

• After all cages have been fitted, an inspection from the inside of the hoppers must be carried out to ensure that all the bags and cages are the correct dimensions and positions.

Important rules for storing filter bags and cages.

• Store the filter bags and support cages in their original packaging.

• The filter bags and support cages must be stored in a dry area.

• Keep the filter bags away from all types of fungi, micro-organisms and insects.

• Protect the filter bags from rodents or other pests.