Конденсатная Силиконовая резина rtv2 для бетонной

- Категория: Silicone Rubber >>>

- Поставщик: Dongguan,Guochuang,Organic,Silicone,Material,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-19-2025 | 0.45 $* | 0.25 $* |

| Aug-19-2025 | 0.76 $* | 0.90 $* |

| Jul-19-2025 | 0.91 $* | 0.8 $* |

| Jun-19-2025 | 0.98 $* | 0.54 $* |

| May-19-2025 | 0.8 $* | 0.99 $* |

| Apr-19-2025 | 0.42 $* | 0.89 $* |

| Mar-19-2025 | 0.96 $* | 0.34 $* |

| Feb-19-2025 | 0.41 $* | 0.7 $* |

| Jan-19-2025 | 0.32 $* | 0.49 $* |

Характеристики

condensation rtv 2 liquid silicone rubber for concrete sculpture mould making

Hi, dear Customers,

Warm welcome to visit our store. We (GC Silicone) is a leading manufacturer of silicone rubber for 13 years in China.

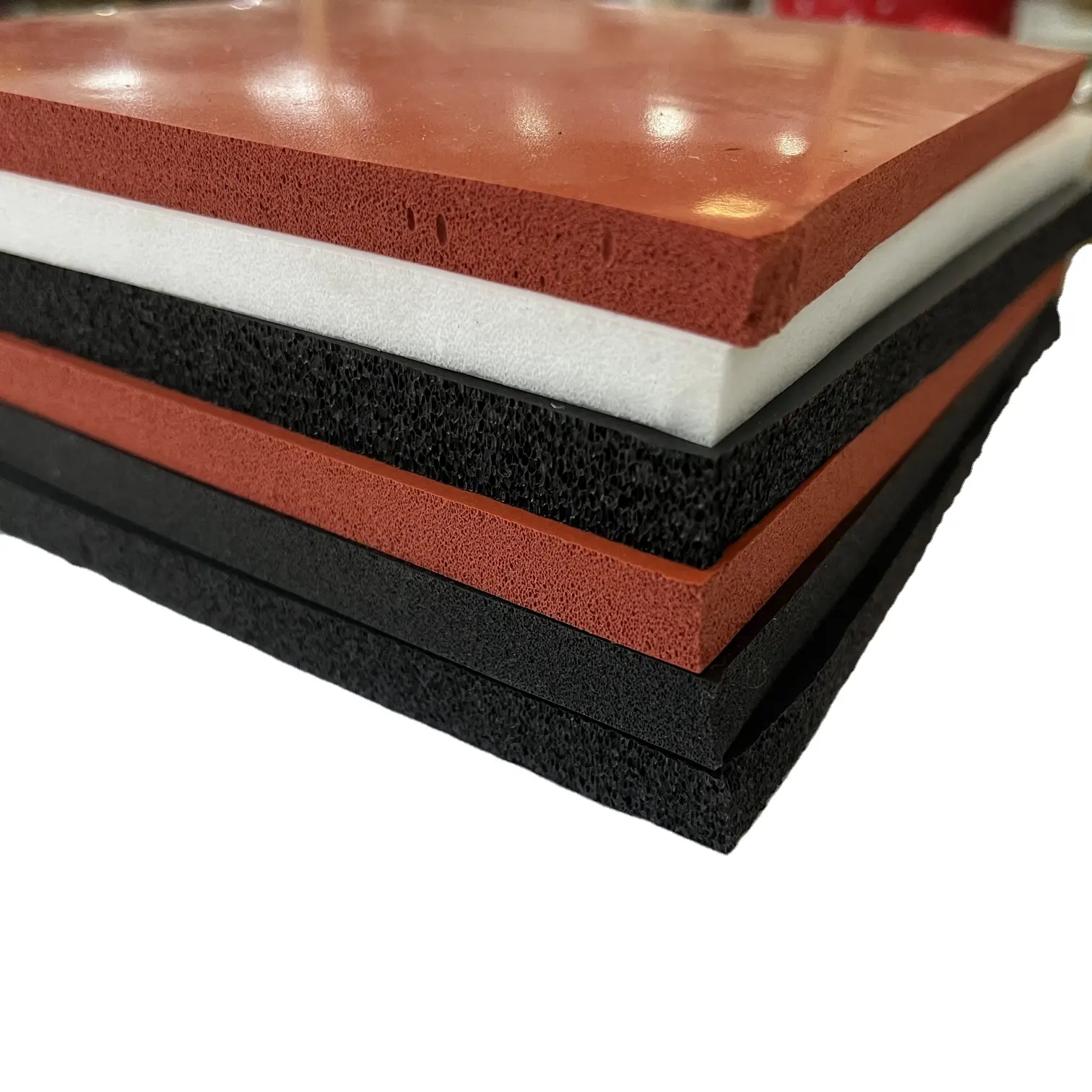

Our products is colorful and being developed all the time. Our main products include

condensation liquid silicone rubber for mold making,

platinum cure liquid silicone rubber,

rtv-2 molding silicone rubber,

medical grade silicone rubber,

life casting silicone rubber and so on.

Hope you can find suitable products on our website https://gcsilicone.en.alibaba.com/.

1. Description of condensation rtv 2 liquid silicone rubber for concrete sculpture mould making

C825 liquid silicone rubber is condensation cure silicone rubber for mold making. The liquid silicone rubber will be cured under room temperature. It's two components, the mixing ratio is 100:2. Part A is a flowable liquid silicone, Part B is the catalyst. It has an exceptional fluidity and good operability.

2. Characteristics of condensation rtv 2 liquid silicone rubber for concrete sculpture mould making

* An exceptional fluidity and good operability, easy to demold

* Good tensile strength and tear strength

* Suitable hardness

* Copy detailed pattern

* Good flexibility

* Eco-friendly

* Long shelf-time &lifetime

3. Application of condensation rtv 2 liquid silicone rubber for concrete sculpture mould making

C825 liquid silicone rubber is perfect molding material, it is suitable to make mold for concrete casting, artificial stone, brick, cement casting, gypsum decorations, plastic product, resin craft, polyester, polyurethane, bronze casting, statues, jewelry, wax, crystal, tire mold, shoe mold, clay casting, ceramic casting. etc.

C825 liquid silicone rubber is mainly suitable for small or middle sized products with delicate pattern by pouring and brushing operation.

4. Datesheet of condensation rtv 2 liquid silicone rubber for mould making

Item No. | Hardness (shore A°) | Viscosity (CPS) | Tensile-strength ( kgf /cm2 ) | Tear-strength (kgf /cm2 ) | Elongation-break(%) | Mixing ratio | operation time (25 ℃ ) | Curing time ( 25 ℃) | shrinkage |

| C825 | 25±1 | 20000±2000 | ≥36 | ≥22 | ≥400 | 100:3 | 20-30 mins | 2~3 h | ≤0.3% |

5. Using instructions of condensation rtv 2 liquid silicone rubber for concrete sculpture mould making

Step 1: Prepare and clean the prototype.

You must make sure your original molds perfect, fix the original mold on a board, then using some assistant material (like cardboard) to make a frame for to surround the prototype. The frame is no need, if we make the mold by brushing way.

Step 2: Take the silicone and catalyst as the ratio 100:2 (silicone : catalyst= 100:2), mix the silicone rubber and catalyst evenly.

Notes: rtv silicone rubber is a kind of flowing liquid and it contains two parts. Part A is a kind of flowing liquid and part B is the curing agent. Remember to mix part A and part B evenly, otherwise the silicone rubber will be partly solidified and this will bring troubles for your final operation. What's more, the finishes molds will have a short life. All of these will cause a waste of silicone rubber.

Step 3: Vacuum pumping.

After mixed the silicone evenly, it is better to release the bubble by vacuum pumping.

Step 4: Pouring cast or brushing cast.

After released the bubble, we can pour/brush the silicone rubber on the prototype.

Notes: Please finishes all the steps within the operation time. If not, it will cause cross linking reaction, and no more further steps will be available. So, we have to pay attention to the pot life and curing time.

Package

25KG/drum vacuum packing for part A +1kg/ bottle catalyst for part B

200KG/drum packing for part A +1kg/ bottle catalyst for part B

Shelf life

1. Twelve(12) months when stored under dry and cool place by original package under 25℃

FAQ:

1. Why will the silicone mold be reused only for a few times?

It can be due to the following reasons:

a. Adding too much silicone oil in to silicon rubber. Silicon oil is an additive which can destroy the molecular weight of silicone rubber and reduce the tension and tear strength.

b. Using the silicon rubber with a high hardness to make molds for small sized products with delicate and intricate designs or the silicon rubber with a low hardness to makes molds for large sized products with simple designs.

(Notes: we should choose the silicon rubber specifically according to the requirements of our products to avoid this problem.)

2. Why does the silicone mold appear to dry outside but wet inside?

Because molding silicone rubber is a kind of condensation silicone rubber, which get solidified after absorbing moisture from the air. In order to provide a significant shelf-life for the silicon rubber, we will dry out the water in the silicon rubber.

Solution: Add 0.1% water into the silicon rubber and Stir over a low speed briefly when you use it.

3. Why is the silicon mold oily?

The molding silicone rubber itself doesn’t contain any oil, so it won’t be oily. If the mold is oily, it may be because you add the compound silicone oil( the compound of silicon oil and white oil). The white oil is not silicon oil but a kind of petrochemicals.

(1) With us your money in safe, your business in safe.

(2) Free sample for testing.

(3) Competitive price.

(4) Strict Q/C (quality of control) management system.

(5) Enough production capacity and timely delivery.

(6) We support customized package and product.

(7) Prompt shipment with professional documents.

(8) Offering professional technical support.

(9) We can make confidentiality agreement with our customs.

(10) We will be here whenever you need.