Косметический смеситель для лосьона оборудование производственная линия

- Категория: >>>

- Поставщик: Guangzhou,Lantliv,Machinery,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-16-2025 | 0.74 $* | 0.42 $* |

| Aug-16-2025 | 0.82 $* | 0.75 $* |

| Jul-16-2025 | 0.4 $* | 0.25 $* |

| Jun-16-2025 | 0.88 $* | 0.64 $* |

| May-16-2025 | 0.84 $* | 0.9 $* |

| Apr-16-2025 | 0.37 $* | 0.51 $* |

| Mar-16-2025 | 0.38 $* | 0.58 $* |

| Feb-16-2025 | 0.64 $* | 0.55 $* |

| Jan-16-2025 | 0.25 $* | 0.46 $* |

Характеристики

Product Description

Features

1. High speed disperser can powerfully mix and disperse viscous solid and liquid materials, and rapidly dissolve many

indissoluble materials such as AES, AESA and LSA during the production of liquid washing products, and so on, saving energy consumption and shortening production period .

2. The main agitator kettle adopts stepless speed variation device, which can reduce the formation of bubbles when the temperature is low and the viscosity is high .

3. The gear pump circulating discharging device can accelerate the forming of products and realize rapid discharging .

Application

1. High speed disperser can powerfully mix and disperse viscous solid and liquid materials, and rapidly dissolve many

indissoluble materials such as AES, AESA and LSA during the production of liquid washing products, and so on, saving energy consumption and shortening production period .

2. The main agitator kettle adopts stepless speed variation device, which can reduce the formation of bubbles when the temperature is low and the viscosity is high .

3. The gear pump circulating discharging device can accelerate the forming of products and realize rapid discharging .

Application

This blending tank is suitable for preparation of liquid detergents (such as cleanser essence, shampoo and shower cream etc.) Integrating blending, dispersing, heating and cooling etc. function, the reacting machine is an ideal shampoo blender chemical reactor.

Technical Parameters

Model | Effective | Stirring power and speed | Homogeneous power and speed | Heating power | ||||||||||

Capacity | KW | R/MIN | KW | R/MIN | Electric heating | Steam heating | ||||||||

LIF-50 | 50 | 0.75 | 0-65 | 3 | 3600 | 6KW | Steam heating energy conservation and environmental protection, selected according to need | |||||||

LIF-100 | 100 | 1.5 | 0-65 | 1.5 | 3600 | 12KW | ||||||||

LIF-150 | 150 | 1.5 | 0-65 | 1.5 | 3600 | 12KW | ||||||||

LIF-200 | 200 | 1.5 | 0-65 | 3 | 3600 | 18KW | ||||||||

LIF-300 | 300 | 1.5 | 0-65 | 3 | 3600 | 18KW | ||||||||

LIF-500 | 500 | 2.2 | 0-65 | 4 | 3600 | 27KW | ||||||||

LIF-1000 | 1000 | 4 | 0-65 | 7.5 | 3600 | 36KW | ||||||||

LIF-1500 | 1500 | 4 | 0-65 | 11 | 3600 | 45KW | ||||||||

LIF-2000 | 2000 | 5.5 | 0-65 | 11 | 3600 | Recommend steam heating | ||||||||

LIF-3000 | 3000 | 7.5 | 0-65 | 15 | 3600 | |||||||||

LIF-5000 | 5000 | 11 | 0-65 | 22 | 3600 | |||||||||

The parameters for reference only, all the machines can be customized accordingly. | ||||||||||||||

Application:

1. Food Industry: Yogurt, Ice Cream, Cheese, Soft Drink, Fruit Jelly, Ketchup, Oil, Syrup, Chocolate etc.

2. Daily Chemicals: Laundry Liquid Soap, Liquid Soap, Liquid Detergent, Hand Wash, Dishwashing Liquid, Facial Foam, Hair Gel, Hair Dyes, Toothpaste, Shampoo, Shoe Polish, Cosmetics etc.

3. Pharmacy: Nutrition Liquid, Chinese Traditional Patent Medicine, Medicine Grease, Biological Products etc.

4. Chemical Industry: Fat, Dissolvent, Resin, Paint, Pigment, Oil Agent etc.

5. Other Industry: Construction Industry, Plastic Industry, Textile Industry, Coal Flotation Agent etc.

2. Daily Chemicals: Laundry Liquid Soap, Liquid Soap, Liquid Detergent, Hand Wash, Dishwashing Liquid, Facial Foam, Hair Gel, Hair Dyes, Toothpaste, Shampoo, Shoe Polish, Cosmetics etc.

3. Pharmacy: Nutrition Liquid, Chinese Traditional Patent Medicine, Medicine Grease, Biological Products etc.

4. Chemical Industry: Fat, Dissolvent, Resin, Paint, Pigment, Oil Agent etc.

5. Other Industry: Construction Industry, Plastic Industry, Textile Industry, Coal Flotation Agent etc.

Detailed Images

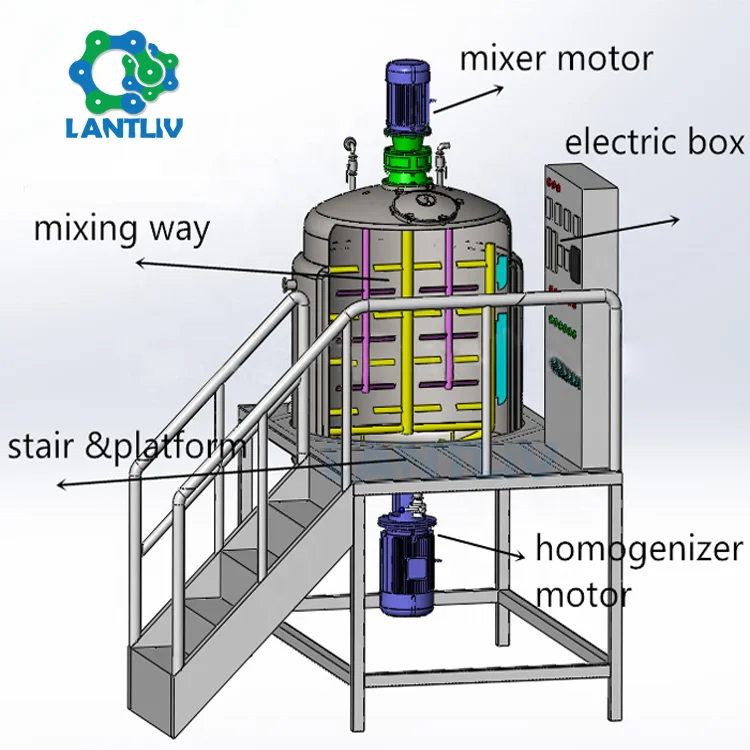

Agitator

1. Structure: Anchor type mixer with PTFE wall scraper.

2. Material: SUS316L

3. Power: 7.5kw or custom made.

4. Stirring Method: One-way stirring or Doube-way stirring.

5. Motor Brand: Siemens, ABB.

6. Running Speed: 0-65RPM, Frequency control.

7. ABB motor with reducer provide strong and stable power for mixer, Panasonic brand frequency inverter, PTFE material scrape blade, Flange shaft coupling.

Homogenizer

1. Structure: Top Homogenizer or bottom Homogenizer.

2. Material: SUS316L

3. Power: 11kw or custom made.

4. Motor Brand: Siemens, ABB.

5. Running Speed: 0-3000RPM, Frequency control.

6. Rotor and stator high shearing homogenizer, soomth emulsion to 2μm, equipped Burgmann seal two sides tungsten seal. NSK bearing. water circulation cooling homogenizer.

Operating electric box

1. Material: SUS304

2. Structure: Button or PLC touch screen.

2. Structure: Button or PLC touch screen.

3. Famous domestic electrical components or custom made.

Workshop production

Our Service

Pre-treat Service

1. Inquiry and consulting support.

2. Sample testing support.

3. View our Factory.

2. Sample testing support.

3. View our Factory.

After-sales Service

1. Technical support online service provided.

2. Technical files service provided.

3. On-site training service provide.

4. Spare parts replacement and repair service provided.

5. Engineers available to service machinery overseas.

2. Technical files service provided.

3. On-site training service provide.

4. Spare parts replacement and repair service provided.

5. Engineers available to service machinery overseas.

Maintenance Guidence

1. Keep the equipment looks clean, no watermarks, smooth.

2. Keep equipment clean, after finished product should be cleaned with hot water as soon as possible.

3. Check on the homogeneous blade usually, Are there loose screws.

4. Homogenizer into the water whether the flow, the water solenoid valve is working properly.

5. Check the mixing gear regularly adequacy of the grease, any abnormal sound.

6. We can supply the whole production line.

2. Keep equipment clean, after finished product should be cleaned with hot water as soon as possible.

3. Check on the homogeneous blade usually, Are there loose screws.

4. Homogenizer into the water whether the flow, the water solenoid valve is working properly.

5. Check the mixing gear regularly adequacy of the grease, any abnormal sound.

6. We can supply the whole production line.

Packing & Delivery

Exhibition

Recommend Products