Машина для литья под давлением холодной камеры из алюминиевого сплава малого

- Категория: Станок для литья под давлением >>>

- Поставщик: Jiangmen,Zhenli,Machinery,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-19-2025 | 0.89 $* | 0.23 $* |

| Aug-19-2025 | 0.37 $* | 0.9 $* |

| Jul-19-2025 | 0.28 $* | 0.24 $* |

| Jun-19-2025 | 0.59 $* | 0.27 $* |

| May-19-2025 | 0.95 $* | 0.12 $* |

| Apr-19-2025 | 0.60 $* | 0.46 $* |

| Mar-19-2025 | 0.49 $* | 0.13 $* |

| Feb-19-2025 | 0.98 $* | 0.31 $* |

| Jan-19-2025 | 0.65 $* | 0.70 $* |

Характеристики

Check this vidieo out to see how our machine works:

https://www.youtube.com/watch?v=s0c-0-eh4HA

Cold chamber die casting machine cast metal ,aluminum die casting machine

Advantage

1.Aluminum casting .

2.Aluminum die casting machine ,brass die casting machine

3.High quality ,adopts precise artificial intelligent computer control .

- aluminum alloy die casting machine ,machine injection aluminum, aluminum injection machine.

Aluminum alloy die casting machine,cold chamber die casting machine.

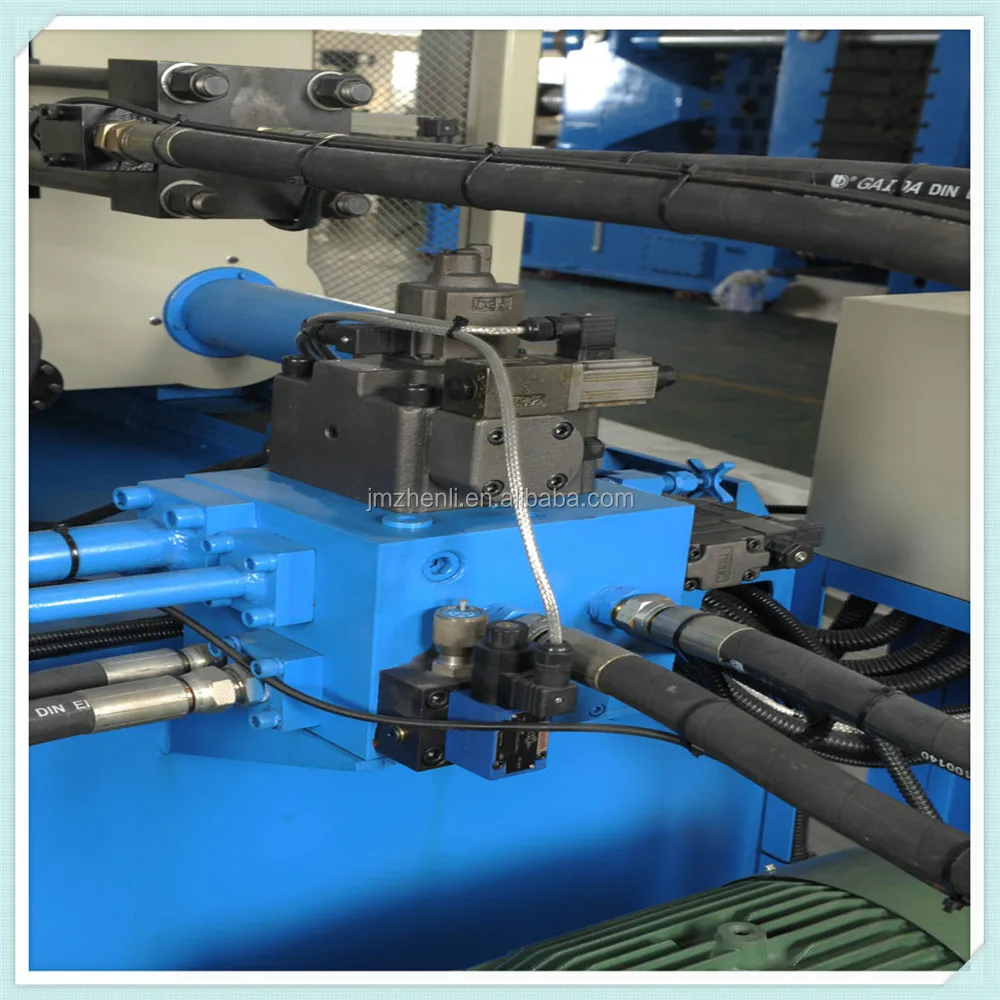

The die casting machine structure adopts 3-pull rod or C- shaped bracket plus hydraulic

elevator deviceand satisfies requirements for moulds .

Adopts high and low pressure-- twin pump with high performance and low noise, saves

energy consumption and improves production efficiency .

Adopts automatic concentrated lubrication system ,directly sets lubrication for times of

machine operation and improves service life of the machine and decrease repair .

The planetary wheel system adopts oil motor to drive the gear mould adjusting machine

structure which is easy to operate ;owns intelligent automatic mould adjusting program ,

precisely calculates the mould locations ,which is convenient for mould replacing and

improves efficiency .

The hydraulic ejector is convenient for control with adjustable ejecting speed .

The hydraulic main system adopts double proportional control ,which is convenient for

adjusting the pressure and speed of every movement in the operation .The outlay precise

suction filter ensures the hydraulic system of cleanness and decreases weariness of the

hydraulic components .

Appliances control:

1. Adopts precise artificial intelligent computer control, it can control and supervise the

data and status of every movement,which is convenient for operation and maintenace .

2.The large screen LCD monitor can realize conversion between Chinese and English.

3.Its powerful memory can store 100 sets of moulding data ,such as ,times,speed,

pressure,traveling distance,mould thickness,options,etc .

4.Has self-check and alarm functions to failures of computer hardware,and display

function of mechanical failures,which is convenient for mechanical failure removal .

5.Mould closing adopts high precise E-ruler positioning test, which can control precise

distance to 0.1mm.

Technological data for ZLC-800

Items | Unit | ZLC-130 |

Clamping Force | NN | 1450 |

Die Stroke | MM | 350 |

Die Thickness(Min-Max) | MM | 250-500 |

Platen Size(HXV) | MM | 650X657 |

Space Between Tie Bars | MM | 410X410 |

Tie bar Diameter | MM | 80 |

Intensification Injection Force | KN | 180 |

Injection Force | MM | 90 |

Injection Strokein | MM | 320 |

Plunger Diameter | MM | 40,50 |

Shot Weight | Kg | 0.7,1.15,1.65 |

Casting Pressure | Kg/cm2 | 141,90,62 |

Casting area | cm2 | 90,140,205 |

MaxCastingAreaUnder40Mps | cm2 | 362 |

Shot Injection Position | MM | 0,-100 |

Plunger Penetration | MM | 115 |

Ejector Force | KN | 108 |

Ejector Stroke | MM | 85 |

Hydraulic Working Pressure | Kgp/cm2 | 140 |

Driving Motor | HP/KW | 15 |

Hydraulic Oil Tank Capacity | L | 300 |

Machine Weight | KG | 6000 |

Machine Dimensions(L×W×H) | MM | 4100X1320X2550 |

We also provide peripheral equipment for customers (optional )

When the machine arrival your destination port,we will appoint one technician

go to your factory, commissioning the machine for you until the machine can

normally produce your product,generally, 3 days is ok.

Located in Jiangmen City----China’ famous motorcycle production base, Zhenli Machinery

Co., Ltd is a high-tech company specializing in R&D, design, production, and after sale

services. Established in 2002, after a decade’s development and dedication, Zhenli now

possesses our own modern factory, imported CNC machining center, gantry milling, planer, grinder, and other advanced equipment. The main products of Zhenli includes “ZL” series

of hot chamber die casting machines, “ZLC”series of cold chamber die casting machine,

serve die casting machines, real-time control die casting machines, magnesium alloy die

casting machines, and peripherals, etc.

Adhering to the business philosophy of “ Keeping Improvement and High Performance”

and the faith of “ Innovation and Integrity” , in pursuit of high quality, reliance and reputation,

Zhenli always places more emphasis on the technology and management. Because of its

advanced technology, high quality and effective management, Zhenli’s hot chamber and cold chamber die casting machine have wined the trust and love of our clients at home and

abroad. Besides, our machines are widely applied in the sectors of toys, appliances, building

materials and hardware, industrial parts, auto parts, electronics, etc.

In a word, our machines almost can satisfy all kinds of production of castings.

Q: Is your company a trading corporation or manufacturer?

A: Our company is a die casting machine manufacturer with

many years experience.

Q: How's your products?

A: We use YUKEN machine valves imported from Japan. Imported components

are used for hydraulic units including REXROTH from Germany and Eaton

VICKERS (America).The Siemens S-7200 control system with LCD monitor(Germany) can accurately control the movement of machine.

Q: How’s your price?

A: We do our best to keep our price as low as possible without sacrificing quality.

Considering the quality of the machine offered, the price is very competitive.

Q: How’s your after-sales?

A: One years after sales warranty.We can also send our engineer to you factory

to installation and commissioning and train your staff

Q: How to place order?

A: We would need you provide your as much detail as possible about your

requirements. Our engineer will choose the suitable size of machine for you.