Автоматический фильтр обратной промывки для промышленной циркулирующей

- Категория: Water Filter >>>

- Поставщик: Beijing,ZhongYuanTong,Science,&,Technology,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-18-2025 | 0.44 $* | 0.62 $* |

| Aug-18-2025 | 0.91 $* | 0.58 $* |

| Jul-18-2025 | 0.65 $* | 0.3 $* |

| Jun-18-2025 | 0.31 $* | 0.20 $* |

| May-18-2025 | 0.38 $* | 0.81 $* |

| Apr-18-2025 | 0.97 $* | 0.66 $* |

| Mar-18-2025 | 0.59 $* | 0.87 $* |

| Feb-18-2025 | 0.57 $* | 0.52 $* |

| Jan-18-2025 | 0.39 $* | 0.46 $* |

Характеристики

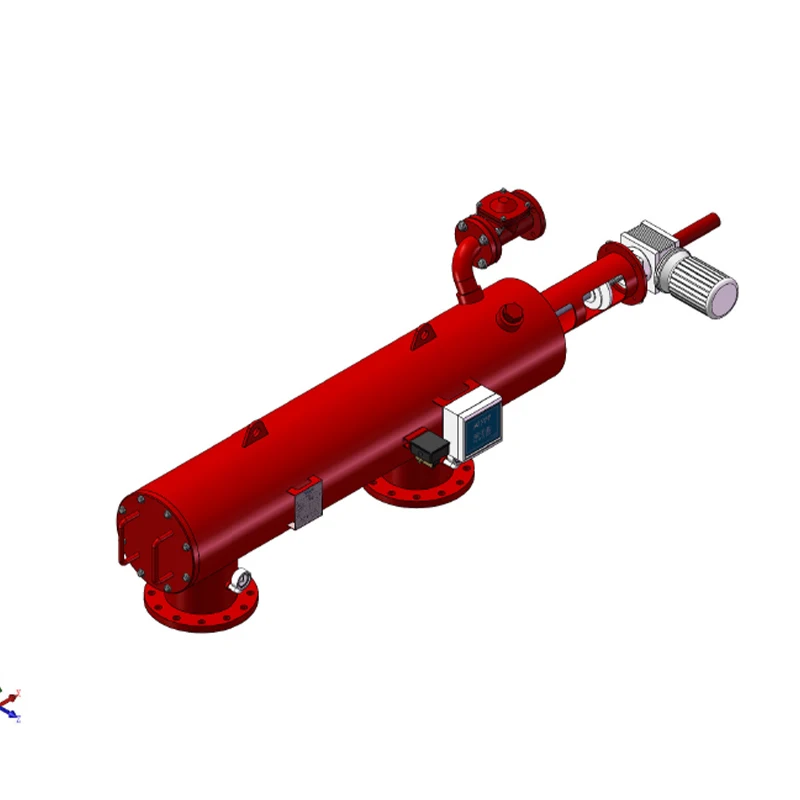

Automatic Backwash Water Screen Filter for Industrial Circulating Water

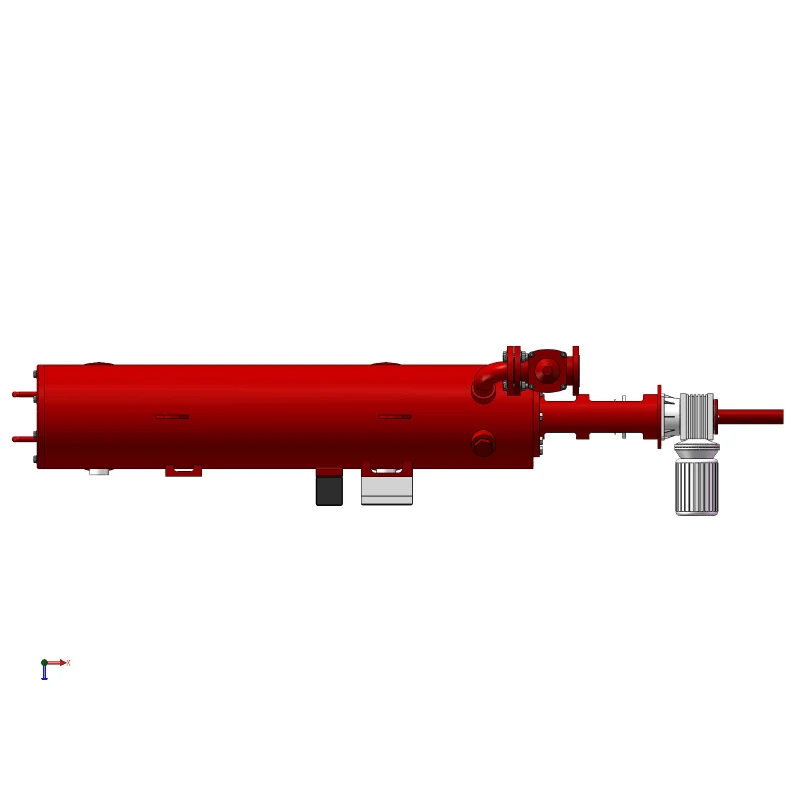

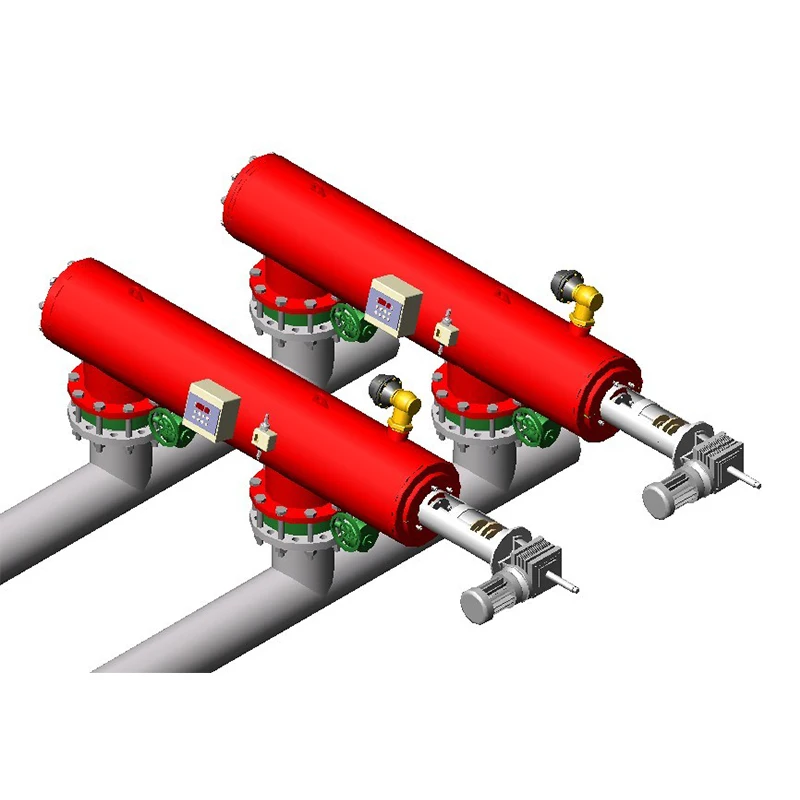

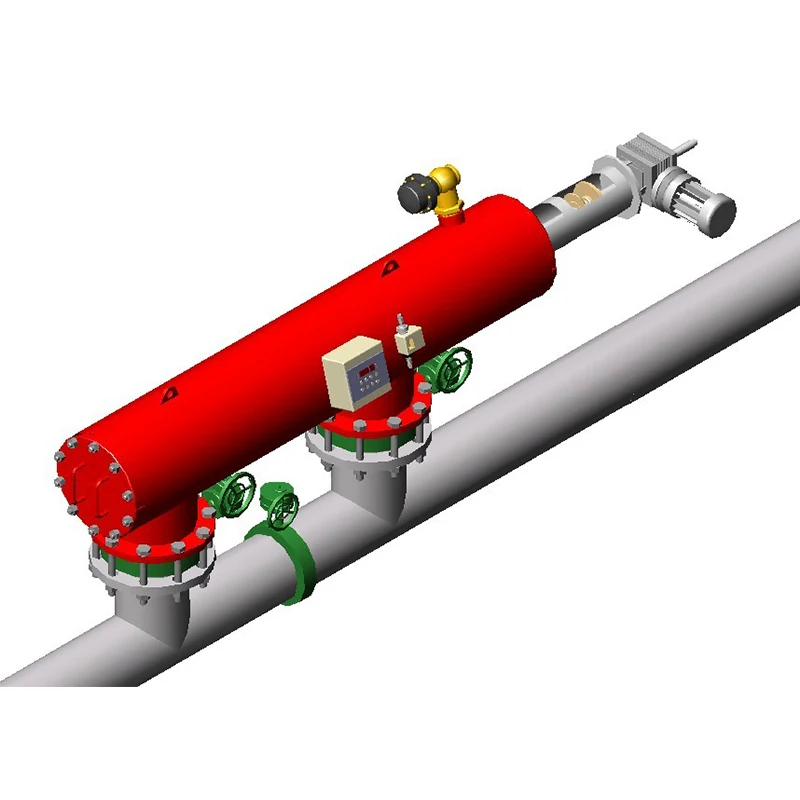

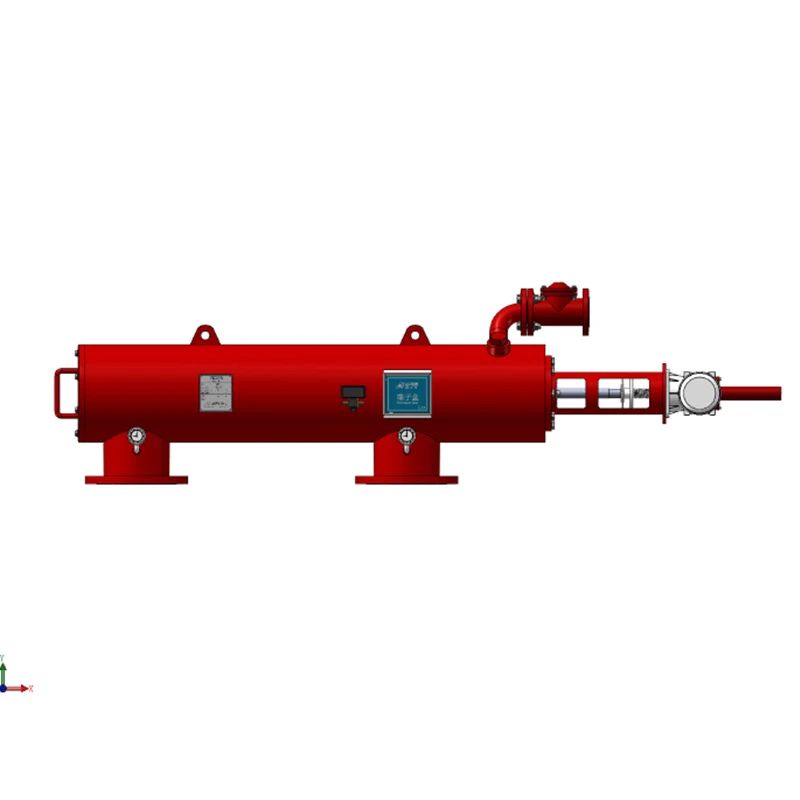

A200 series have two-stage filtration (coarse screen and fine screen). Suction nozzle type cleaning method, horizontal installation.

This automatic electric filter combines the advantages of high quality filtration from different water sources (sewage, reservoirs, rivers, lakes, etc.) with self-cleaning feature, offering the customer a continuous water supply.

The filters are designed for use in wide range of Industrial, municipal and irrigation applications.

Cleaning of the screen is performed once the pressure loss (ΔP) across the filter has reached the preset value [up to 0.5 bar (7psi)].

The filter is equipped with a coarse screen that protects the finer screen from stones and larger particles.

The flushing valve opens and pressure in the flushing chamber and the dirt collector is significantly lowered resulting in a suction process via the suction nozzles to the dirt collector and from there through the flushing valve outside. The electric motor simultaneously rotates the dirt collector and moves it along its axis. The combination of the vertical movement and rotation guarantees that the suction nozzles will cover the entire internal screen surface, efficiently cleaning the screen. The whole process takes 12-18 seconds.

During the whole process water supply is uninterrupted.

Filter flow | 80-1500m³/h |

Max. recommended working pressure | 10bar/16bar/25bar |

Min. operating working pressure during backwash | 2.5bar |

Water temperature range | 0 ~ 65 °C |

Available filtration | From 50micron |

Pressure loss | < 0.1bar |

Connections | Flange |

Backwash time | 12~18 sec |

Water consumption during backwash | 1%-3% of filtered water |

Control model | DP /PLC Timing /Manual |

Cleaning way | Suction nozzle |

Drive way | Motor drive |

Fine screen | Stainless steel 304 mesh, supported by a PVC cylinder |

Coarse screen | PVC |

Filter housing material of construction | Carbon steel ST37-2/SS304/SS316 |

Sewage way | Fully automatic |

Installation | Horizontal |

Rated operating voltage | 3-ph, 380v, 220v, 50Hz |

Our company can manufacture the filter according to the user's requirements of size,material (eg.carbon steel, stainless steel), color and other special requirements.

Model | DN | Flow | Filtration Area | Weight | Dimensions | |||||

|

|

|

|

| D | H | L | L1 | L* | |

| inch | mm | m³/h | cm² | Kg | mm | ||||

A204 | 4 | 100 | 80 | 4900 | 145 | 273 | 245 | 2260 | 900 | 1400 |

A206 | 6 | 150 | 150 | 4900 | 180 | 325 | 275 | 2330 | 900 | 1400 |

A208 | 8 | 200 | 300 | 4900 | 200 | 325 | 275 | 2530 | 900 | 1400 |

A210 | 10 | 250 | 400 | 6670 | 320 | 426 | 333 | 2710 | 1100 | 1600 |

A212 | 12 | 300 | 600 | 10050 | 400 | 426 | 335 | 3460 | 1100 | 2350 |

A214 | 14 | 350 | 900 | 11550 | 480 | 480 | 367 | 3460 | 1270 | 2350 |

A216 | 16 | 400 | 1100 | 11550 | 560 | 530 | 400 | 3600 | 1270 | 2500 |

A218 | 18 | 450 | 1500 | 11550 | 745 | 610 | 440 | 3600 | 1270 | 2500 |

AIGER Self-Cleaning Filter is widely used in agricultural irrigation, municipal project, power industry, paper making, coal, metallurgy and other industries.

Packing :

The equipment is wrapped in plastic film and then loaded into the wooden box.

Q: Are you trading company or manufacturer ?

A: We are factory.

Q: How long is your delivery time?

A: Generally it is 25 days, and it is also according to quantity.

Q: Do you provide samples ? is it free or extra ?

A: Sorry, we could not offer the sample for free charge.

Q: What is your terms of payment ?

A: Payment<=1000USD, 100% in advance. Payment>=1000USD, 30% T/T in advance ,balance before shipment.