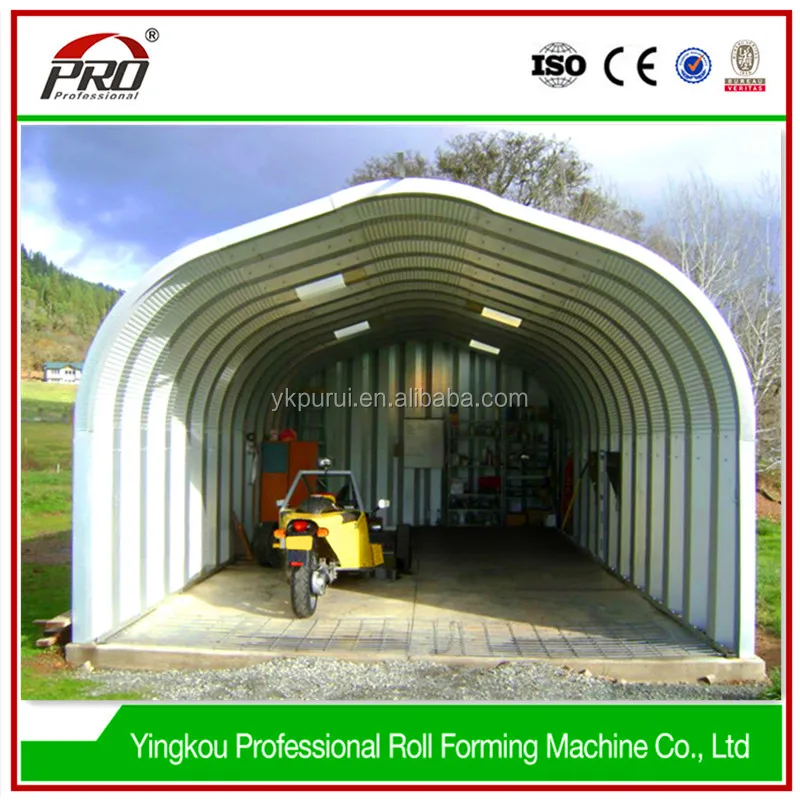

Винтовое соединение листового металла кровельные рулоны прокатная машина

- Категория: >>>

- Поставщик: Yingkou,Professional,Roll,Forming,Machine,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-19-2025 | 94010.34 $* | 98711.75 $* |

| Aug-19-2025 | 93220.45 $* | 97881.83 $* |

| Jul-19-2025 | 78210.21 $* | 82121.69 $* |

| Jun-19-2025 | 91640.76 $* | 96222.33 $* |

| May-19-2025 | 79790.78 $* | 83780.24 $* |

| Apr-19-2025 | 90060.48 $* | 94563.90 $* |

| Mar-19-2025 | 89270.45 $* | 93734.82 $* |

| Feb-19-2025 | 88480.69 $* | 92904.7 $* |

| Jan-19-2025 | 87690.51 $* | 92075.0 $* |

Характеристики

Technical Parameter of PRO-S1000-680

Hydraulic Decoiler | ||

Dimension | 2700X1500X1900 mm, Weight:1.5 T | |

Load Bearing | 8 T | |

Main Shaft | ¢200mm | |

Motor Power | 3.0KW | |

Decoiling Width | 600-1000mm | |

Decoiling Thickness | ≦1.5mm | |

Inner-Diameter | 470-520mm | |

Pressure Arm Cylinder | 200 mm | |

Forming Machine | ||

Dimension | 6500X1400X1400mm, Weight: 6 T | |

Motor Power | 7.5KW | |

Roller Material | 45# High-Quality Steel, Quenched HRC 55~65, Hard Chrome Plating | |

Shaft Material | ¢65, 45# High-Quality Steel, Galvanized | |

Stands of Forming | 10 Steps | |

Feeding Width | 1000mm | |

Effective Width | 680mm | |

Rolling Thickness | 0.6-1.5mm | |

Using Rate | 68% | |

Bending machine | ||

Dimension | 3500X1500X2600mm, Weight: 2 T | |

Servo Motor Power | 1.5KW | |

Hydraulic Station Motor | 11KW | |

Hydraulic Oil Pump | Gear Pump, Pressure: ≦16Mpa | |

Mold | 1 Set (Pleat Pressed) | |

Controlling System | Whole Machine Adopts PLC, Touching Screen, Frequency Converter, Servo Motor as Controlling System |

Power | 380V/50Hz/3 Phases |

Accessories List

No | Name | Qty. |

1 | Decoiler | 1 Piece |

2 | Leveling machine | 1 Piece |

3 | Shearing machine | 1 Piece |

4 | Roll forming machine | 1 Piece |

5 | Hydraulic punching machine | 1 Piece |

6 | Molds | 1 Sets |

7 | Support platform | 1 Piece |

8 | Chain | 3 Pieces |

9 | Half section | 3 Pieces |

10 | Bearing | 4 Pieces |

Design Drawing

This is machine making 1000-680 plate type. If you want machine making orther plate type, please tell us and we have professional team to design for you!

Technological process

Loading (Load & Expand Steel Coil on Decoiler) → Feeding & Flattening & Sizing (Prepare Flat Sheet for Punching) → Edge-Punching & Ends-Punching on Flat Sheet → Shearing Punched Sheet → Roll Forming Sheared Sheet → Bending Roll Formed Sheet.

Hydraulic decoiler

Loading bearing is 8T

Weight is 1.5T

Main shaft:200mm

Motor power:3.0kw

Decoiling width:600-1000mm

Pressure arm cylinder:200mm

Rollers and Shafts Detail

Our screw joint sheet metal roofing rolls rolling machine’s rollers and shafts are connected with pin inside and screw outside, and with reinforcing design on both sides of rollers, which can fix the rollers and shafts tightly without deformation.

Main Machine Detail

Rollers material 45# high-quality steel,quenched HRC5~-65,hard chrome plating

Cutting Detail

Cutting material: Cr12 MoV, best and sharpest cutting material.

Bending Detail

Servo motor power:1.5kw

Hydraulic station motor:11kw

Hydraulic oil pump:gear pump

Pre-Sales Service

* Inquire and consult support.

* Design machine you want.

* View our Factory.

* Provide the technical support.

During the Production

* We will send photo of making machine process detail every once in a while.

After-Sales Service

* Training how to use machine.

* Training how to make project.

* Engineers available to service machinery overseas.

FAQ

Q: Can you make the machine according to my design or photo type? A: Yes, we have an experienced team for working out the most suitable design and production plan for the machine according to your demand or photo type that you are going to book with us. |

Q: Are you a factory or trading company? A: We are a factory located in YingKou city, LiaoNing Province, China. Our city is near Beijing. All clients from abroad and home are warmly welcome to visit our factory! |

Q: How do you guarantee the quality of the products? A: Every section of our production has strict manufacture process, than professional inspectors check every section of the production, next the production will work for testing quality, which must be 100% quality assurance. Unqualified resolute don't a better factory. |

Payment

T/T( 30% by T/T in advance, the rest 70% to be paid by T/T after you inspect the machine in seller's factory before delivery )

PRO Arch 600-305 Sheet Metal Roofing Rolls Rolling Machine.

PRO Arch 1000-680 Sheet Metal Roofing Rolls Rolling Machine.

PRO Flat Sheet Metal Roofing Rolls Rolling Machine.