Высокотемпературная машина для окрашивания

- Категория: >>>

- Поставщик: Wuxi,Sunsky,Machinery,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-16-2025 | 0.82 $* | 0.19 $* |

| Aug-16-2025 | 0.92 $* | 0.67 $* |

| Jul-16-2025 | 0.43 $* | 0.54 $* |

| Jun-16-2025 | 0.73 $* | 0.7 $* |

| May-16-2025 | 0.42 $* | 0.60 $* |

| Apr-16-2025 | 0.70 $* | 0.87 $* |

| Mar-16-2025 | 0.17 $* | 0.51 $* |

| Feb-16-2025 | 0.41 $* | 0.90 $* |

| Jan-16-2025 | 0.64 $* | 0.19 $* |

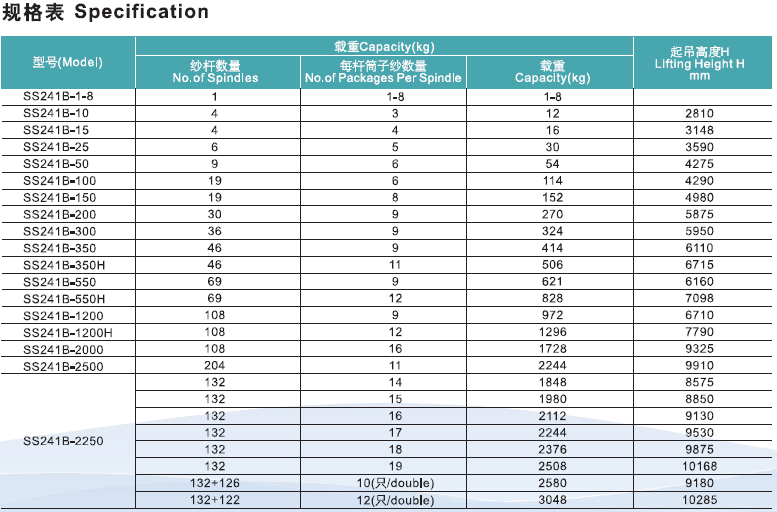

Характеристики

SS241B Yarn Dyeing Machine is suitable for dyeing processing cotton , polyester , acrylic , nylon , sheep , whool , T/C , acrylic /cotton blends , polyester , wool blends , hemp and cotton blends or any kind of blended yarn.

1. Low liquor ratio 1:5-6

2. Design Temperature 160°C

3. Max working temperature:140°C

4. Max working pressure:0.45 Mpa

5. Savings in power and steam consumption by 15-20%

6. Heating time:approx 30 min for temp rise 20°C -130°C(at steam pressure of 0.70 Mpa)

7. Cooling time:approx 20 min for 130°C-80°C (at cooling water pressure of 0.3Mpa)

1. Heating control

2. Cooling control

3. Dosing/discharge call signal

4. Sampling call signal

5. Cooling water fill: temperature below 85°C

6. Hot water fill: temperature above 85°C

7. Water drain: drain to sewage treatment system(Optional)

8. Water drain: temperature below 85°C

9. High-Temperature Drain

10. Overflow Rinse

11. Dyestuff dose signal

12. Flow reversing control

13. Dosing tank: water fill, water drain, heating, and stirring controls

14. Stock tank: water fill, water drain, heating, and stirring controls(Optional)

15. Program end call signal.

Yarn Dyeing Machine Workshop

Due to increasing environmental pressures and textile constantly updated,we have successfully developed a new generation / low liquor ratio 1:3.5~5 dyeing machine on the basis of many years professional manufacturing experience,it's environmental protection and energy saving fabric dyeing machine OH/UH series and low liquor ratio package dyeing machine.We look forward to serving more customers at home and abroad.

Sunsky is an experienced machinery manufacturer since 2004,it's located in Wuxi,JiangSu Province,China(50mins by train from Shanghai).We're focusing on dyeing and finishing machines for various textiles.After a decade of innovations and development, Sunsky becomes an expert in the field of textile dyeing machines, including normal temperature dyeing machine, high temperature dyeing machine, pre-treatment and after-treatment machines. We make designs according our customer's requirement, continuously improve our techniques, optimize designs and also take the issue of environment into consideration. Sunsky dyeing machine has been well received by domestic and foreign customers.On the basis of 10years professional manufacturing experience,we have successfully developed a new generation of liquor ratio 1:3.5~5, energy saving type OH/UH,and 1:2.8~3.5 yarn dyeing machine...

- Your any inquiries will be replied within 12 hours.

- We offer you professional service in fluent English.

- Quality: we have QC on each process in production.

- We will give the right schedule and quality machine.

- Without man-made faults,the warranty is one year,and spare parts can be replaced within 3months since the delivery of dyeing machine.

- Engineers available to service machinery overseas,commissioning and technical support,etc.

Electrical Control Panel(Setex+PLC from Germany)