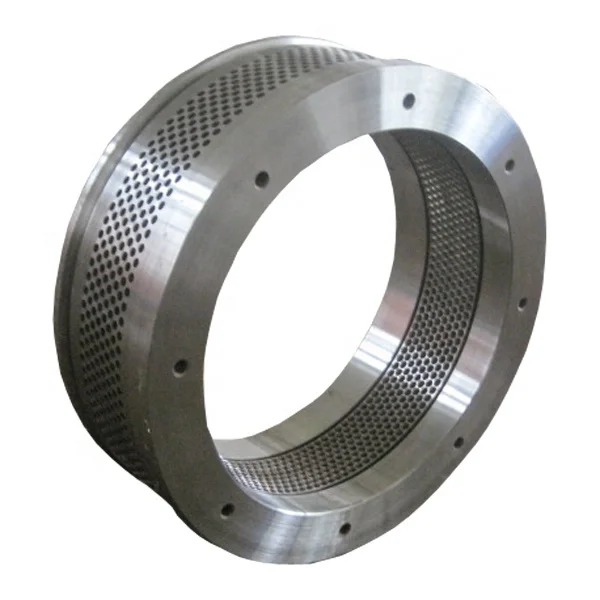

Мануфактура предложение ring die для Пелле мельница/гранулы под давлением с 20-летним

- Категория: Food Processing Machinery Parts >>>

- Поставщик: Liyang,Weifeng,Equipment,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-17-2025 | 0.56 $* | 0.23 $* |

| Aug-17-2025 | 0.52 $* | 0.16 $* |

| Jul-17-2025 | 0.50 $* | 0.28 $* |

| Jun-17-2025 | 0.12 $* | 0.45 $* |

| May-17-2025 | 0.36 $* | 0.93 $* |

| Apr-17-2025 | 0.30 $* | 0.4 $* |

| Mar-17-2025 | 0.69 $* | 0.23 $* |

| Feb-17-2025 | 0.16 $* | 0.43 $* |

| Jan-17-2025 | 0.57 $* | 0.43 $* |

Характеристики

Manufactory offer high quality pellet die, mould for pellet mill:

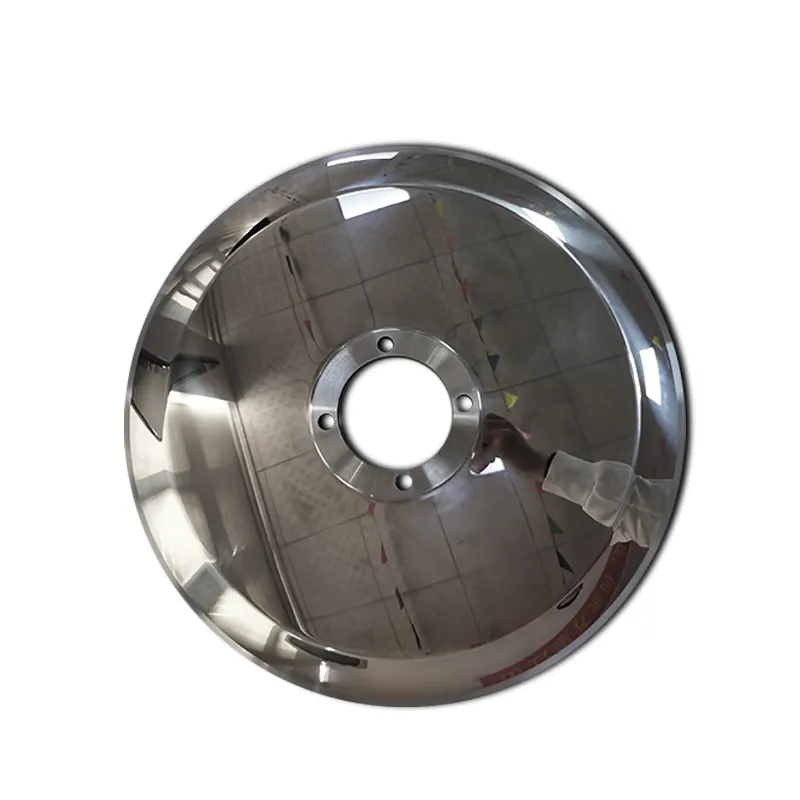

We are a professional manufacturing factory for Ring Die,Pellet Die,Flat die,Feed Mill Pellet Ring Die,Pellet Mill Ring Die,Animal Feed Pellet Mill Ring Die,Pellet Machine Ring die,Pellet Press Ring Die,Wood Pellet Machine Ring Die,ring die accessories etc. spare parts.

Range of pellet die spare parts' Application

Applicable for Biomass pellet machine: wood pellet mill, sawdust pellet mill, grass pellet mill, straw pellet mill, crop stalk pellet machine, alfalfa pellet mill etc.

Applicable for Fertilizer pellet machine, all kinds of animal/poultry/livestock feed pellet machine too.

Introduction of pellet die

1.Material of the ring die: X46Cr13 /4Cr13(stainless steel), 20MnCr5/20CrMnTi (alloy steel) or customized

2. Hardness of ring dies: HRC54-60.

3. Diameter of ring die can do: 1.0mm up to 28mm

4. Pellet die type can do: Ring Die or Flat Die

5. Outer diameter can do: Outer diameter up to 1800mm

6. Pellet Die model we can customize:

CPM, Buhler, CPP, OGM, Zhengchang(SZLH/MZLH), Amandus Kahl, Muyang(MUZL), Yulong(XGJ), AWILA,PTN, Andritz Sprout, Matador, Paladin, Sogem, Van Arssen, Yemmak, Promill; etc. We can customize for you according to your drawing.

For Zhengchang pellet mill: SZLH250, SZLH300,SZLH320,SZLH350,SZLH400,SZLH420,SZLH508, SZLH678, SZLH768, etc

For Muyang pellet mill: MUZL180, MUZL350, MUZL420, MUZL600, MUZL1200, MUZL610, MUZL1210, MUZL1610, MUZL2010;

MUZL350X, MUZL420X, MUZL600X, MUZL1200X(Especially for shrimp feed pellet, diameter: 1.2-2.5mm)

For Awalia pellet mill: Awalia 420, Awalia350, etc

For Buhler pellet mill: Buhler304, Buhler420, Buhler520, Buhler660, Buhler900, etc.

For Kahl pellet mill(Flat die): 38-780, 37-850, 45-1250, etc

Process for making pellet die

Blank raw material Forging---Rough turning---Half finished turning---Drilling the hole---Grinding inner bore---Treaded hole--- Keyway milling---Heat treatment---Finish turning---Package

Compression Ratio of Ring Die

Generally speaking, the higher the compression ratio, the denser the finished pellets. But it does not mean that the higher the compression ratio, the better the pellet quality.

Compression ratio should be calculated based on raw material for making pellets and type of feed.

With many years pellet die manufacturing and research experience of WEIFENG Company, we provide some general data of ring die's compression ratio for your reference:

Buyers can customize dies with different hole diameter and compression ratio, according to different situation and requirement.

Item | Hole Diameter(mm) | Compression Ratio |

pellet die for animal feed pellet machine |

|

|

Poultry&livestock feed | 2.5 - 4 | 1:4-1:11 |

Fish feed | 2.0 - 2.5 | 1:12-1:14 |

Shrimp feed | 0.4 - 1.8 | 1:18-1:25 |

Ring die for biomass pellet machine | 6.0 - 8.0 | 1:4.5-1:8 |

The most common structure of die hole are straight hole; release stepped hole; external conical hole and internal conical hole, etc. Different die holes structure are suitable for different raw material and feed formula for making pellets.

Packing ways of our pellet die:wooden case or according to your requirement

our service of pellet die

We all provide after-sale support for you, repair maintenance, installation and debugging services and accessories. If you have any needs, can feel free to contact us, our technical staff will warmly for your service.

Any questions, pls feel free to contact me!