Прозрачные водонепроницаемые супер гидрофобное нано-покрытие для ковровых

- Категория: Резиновое покрытие >>>

- Поставщик: Anhui,Sinograce,Chemical,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-16-2025 | 0.27 $* | 0.25 $* |

| Aug-16-2025 | 0.3 $* | 0.93 $* |

| Jul-16-2025 | 0.9 $* | 0.10 $* |

| Jun-16-2025 | 0.57 $* | 0.85 $* |

| May-16-2025 | 0.55 $* | 0.13 $* |

| Apr-16-2025 | 0.12 $* | 0.57 $* |

| Mar-16-2025 | 0.80 $* | 0.59 $* |

| Feb-16-2025 | 0.79 $* | 0.50 $* |

| Jan-16-2025 | 0.67 $* | 0.71 $* |

Характеристики

transparent water proof super hydrophobic nano coating for carpet

Feature

lMake the fiber alcohol resistant

lNonflammable water based emulsion

lStability while using with other additives together

lDon’t need to add the crosslinking agent to the system

lEndow the fiber with excellent waterproof and oil proof properties

lHydrophobic coating applied by spray, foam, coating, wet roller, padding, dip-coating and other ways

Chemical Composition

lPerfluorinated polymer emulsion

Technical Data

lAppearance: Milky emulsion or faint yellow emulsion

lpH: 3-5

lSolid content: ~20%

lIonicity: weak cation

lSolubility in water: soluble easily in water

The hydrophobic coating product doesn’t contain alkyl phenol polyoxyethylene ether compounds (APEO). The perfluorinated octyl sulfonamide (PFOS), heavy metals and perfluoro caprylic acid (PFOA) content are all below 1 PPM. The product meets the export standards.

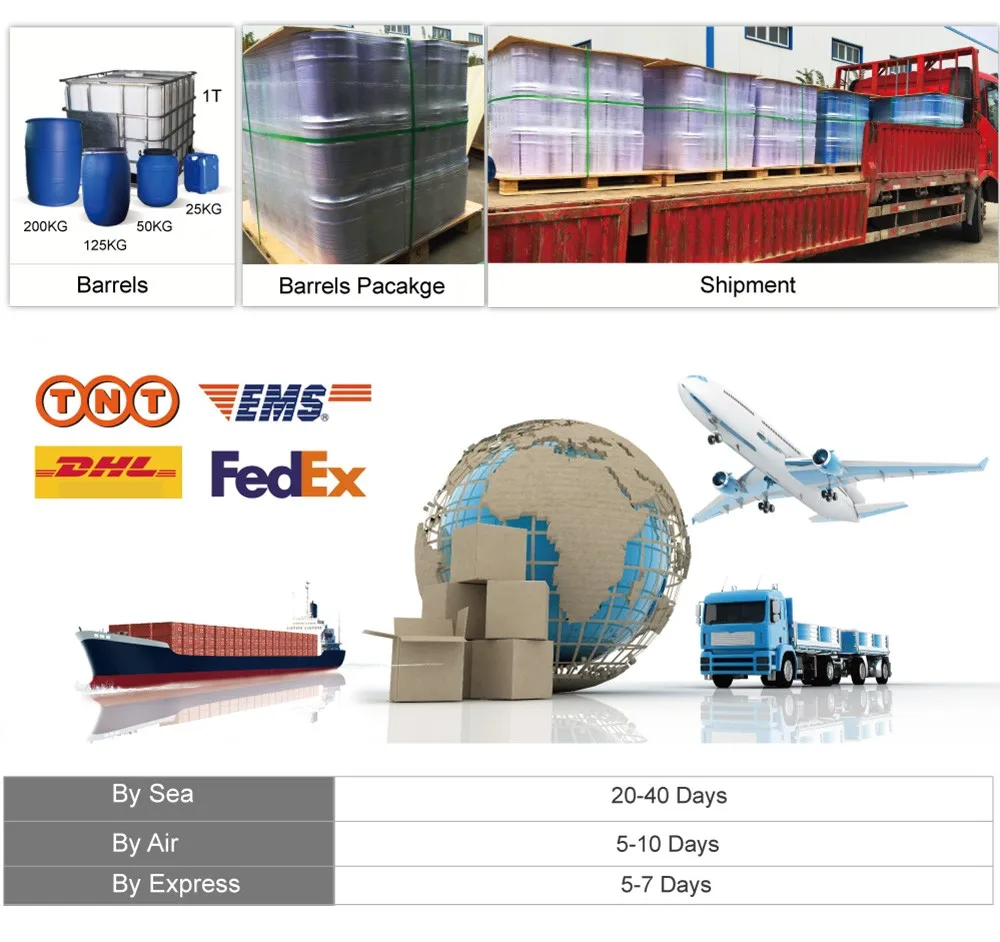

Package, storage and transportation

lAvailable in200 kg/barrel or 25 kg/barrel

lStorage period: 12 months in closed containers, shady and dry place

lAccording to non-dangerous goods transport

Applied Technology

1.The preparation of textile fabric

lIn order to get the optimal effect, you must remove the additives on the surface of fabric, such as wetting agent, dyeing auxiliary, softening agent and so on.

lPieces of fabric fiber rate must be less than 1.5% and recommends testing by AATCC97. In addition, ensure that the fabric in weak acid, alkali content less than 0.05% and recommend testing by AATCC 144.

lAvoid reducing effect, raising and sand grinding should be carried out before finishing; Some mechanical finishing, such as calendering, electro-optic and brush can be conducted between drying and baking.

2.The preparation of solution

lFirstly, add the quantitative PF-206 into the clean container, and then the quantitative water is added into. Finally, stir the solution at a low speed until uniformity.

lPreferably, have a test before mass production. For new fabric, using PF-206 to preparation the duplicate worksolution, the one is not to adjust pH value, the other is adjustedthe pH value to 4 by adding 0.1% acetic acid. According to the same test conditions to test them, find the optimal pH value.

lWhile using it with crosslinking agent, penetrating agent, crease resistant resin and other additives together, all of these additives should be separately diluted and avoid additives raw solution mixing.

3.The recommended dosage

lPolyester fabric:10~30 g/L

lNylon fabric:10~ 30g/L

lPolyester or cotton fabric 20~40 g

4.The application method

lPadding

lpH value (according to the test result)

lPredrying temperature: 110~130℃

lBaking: Recommended 170℃ (fabric surface) by the stenter setting machine and the baking time is 60 seconds

5.Notes

lWhile using it with crosslinking agent, penetrating agent, crease resistant resin and other additives together, please must check its intermiscibility with other additives by test.

lAgitate the solution while preparing the PF-206 solution.

lThe product can increase the color degree and please check the color after processing.

lBaking should be fully to ensure the effect.

lPlease run out of the prepared solution within 12 hours.

lDue to the resin residue easily adhesion and accumulation on the roller, roller drying is not good method.