3 рукы 5-станция для ротационной формовки

- Категория: Rotational Molding Machine >>>

- Поставщик: Ningguo,Jingcan,Rubble,&,Plastic,Products,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-16-2025 | 0.55 $* | 0.69 $* |

| Aug-16-2025 | 0.59 $* | 0.19 $* |

| Jul-16-2025 | 0.17 $* | 0.66 $* |

| Jun-16-2025 | 0.28 $* | 0.73 $* |

| May-16-2025 | 0.24 $* | 0.0 $* |

| Apr-16-2025 | 0.1 $* | 0.78 $* |

| Mar-16-2025 | 0.81 $* | 0.41 $* |

| Feb-16-2025 | 0.38 $* | 0.13 $* |

| Jan-16-2025 | 0.37 $* | 0.79 $* |

Характеристики

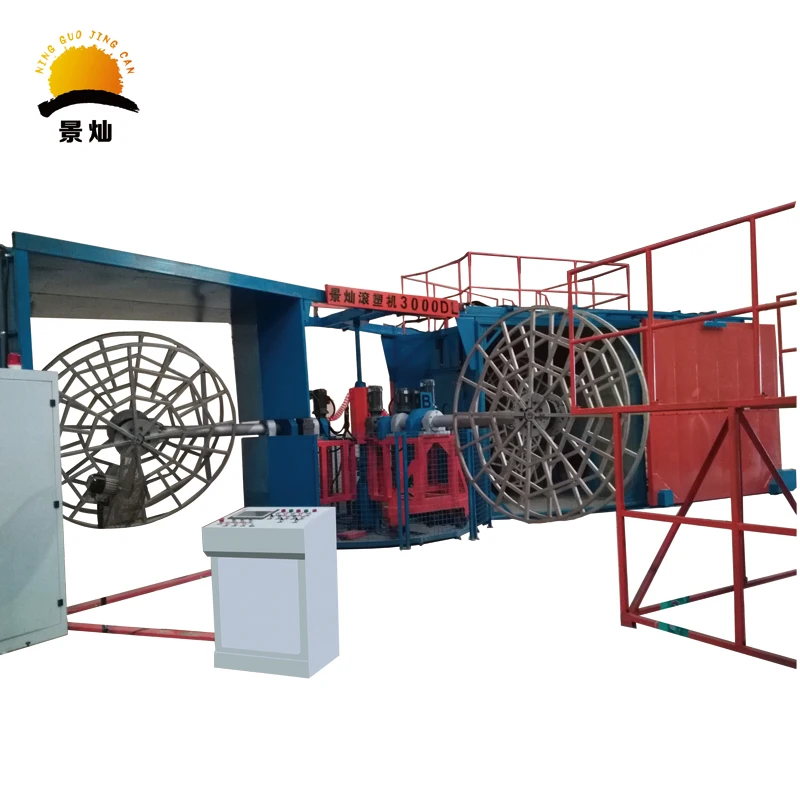

Carousel rotomolding machine

The JC series of independent trolley-type rotomolding equipment is a common form of equipment used in the rotary molding industry today. The device not only provides the versatility of the shuttle device and the fixed boom device, but also provides a more automated and complete processing method than any other device.The rotational molding machine includes an air circulation heating chamber, an air/water cooling chamber, a center tower rotating mechanism, and a control system. The independent rotomolding machine is divided into three types: three-arm four-station, three-arm five-station, four-arm six-station.The rotation of any one of the arms of the device is independent, and different process arms of the device can set different process parameters to meet the processing needs of different products. Each frame can be set in the heating chamber and the cooling chamber for different running times to meet the production needs and to meet the needs of optimized products.

Working Cycle

Available with up to 6 stations for maximum flexibility:

1 Cooking and moulding the article;

2 Intermediate phase waiting for cooling;

3 Mould cooling station;

4 Waiting station for mould opening;

5 Material loading;

6 Waiting or pre-moulding station for second layer or sandwich.

Depending on the customer requirements, the work stations can be arranged in a different way.

Main Features

1 PLC controls to manage the machine;

2 Long life gear in the head of the arms ;

3 Easy operations;

4 New air flow design of the cooking chamber;

5 Big capacity of the arms;

6 New system for opening and closing of the doors of the oven to save the space;

7 Highly efficient thermal insulation of the cooking chamber;

8 Electronically controlled burner for reduced fuel consumption with different fuels;

9 Heating with high velocity forced air circulation in closed circuit;

10 Adjustable deflectors for optimal heating air flow to the moulds;

11Oven fitted with doors and sliding gates;

12 Cooling chamber in galvanized steel or stainless steel;

13 Cooling via air and water mist spray;

14 Primary and secondary rotation movements through gear wheels and gear motors controlled by frequency inverters;

15 Individual carriages movement controlled by proximity sensors;

16 High carrying capacity straight/offset/C arms assembled in a single block & easily interchangeable;

17 Operator touch screen control for total management of the working cycle in the language of the operator;

18 Oven temperature measurement and adjustment in real time of the system to heat the molds;

19 Remote operator console for easy loading and unloading operations.

Machine Parts

The equipment is designed in conjunction with the recirculation system of high capacity air (equipped with starting and speed control by frequency inverter) and the heating system with high efficiency in each cycle.

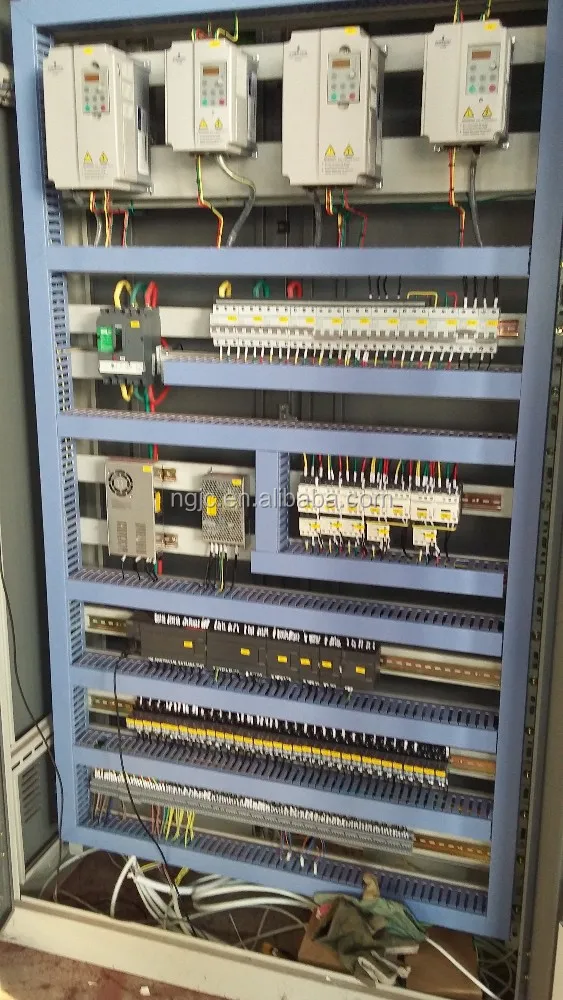

Electrical Part:

It is equipped with a General Panel where are installed and interconnected all programmable and eletromechanical components such as PLC (Programmable Logic Controller), computer, contactors, motors breakers, power supplies, transformer, VFDs (variable frequency drives), push buttons, selector switches and light/sound alarms. This panel is mainly used to set the recipe parameters for the production.

Control Parts:

The PLC is loaded with a software management control system, which gathers information from multiple sensors such as temperature and pressure, installed in various parts of the machine, doing all the interlock and control functions of machine operation and providing a specific and concise input to the controller of the gas burner.

Arms:

The Carousel machine model can be equipped with Straight arm or optional Offset arm "C", both built with a reinforced structure and heat treated for steel stress release.

NINGGUO JINGCAN RUBBER & PLASTIC PRODUCTS CO.,LTD

Ningguo City Jingcan Rubber & Plastic Products Co.,Ltd is a professional supplier in rotomolding equipments, molds and products. 20 years experience in rotomolding Industry, start from rotomolding water tank with simple extensive to precision parts of auto like fuel tank and plastic tubes, We always develop different equipment to meet different technology requirement. In order to promote the development of rotational molding industry, JingCan is committed to helping developing countries realize the localization of rotational molding production and providing a one-stop solution for new rotational molding factories with customers in Southeast Asia, the Middle East, Africa, the United States, Australia and South America, rotational molding equipment received the customer's consistent high praise. JingCan is willing to all customers and common development, customer needs and development achievements in the development of their own.Warmly welcome customers at home and abroad visit the guide.

Office Factory Some products Storage

Exhibition

Products Name with link

91.8% Response Rate

Products Name with link

91.8% Response Rate

Products Name with link

91.8% Response Rate

1.Shipping by sea.

2.We Use bubble film for waterproofing.

Q:Will you accept OEM?

Yes,OEM service is accepted.

Q:What kind of payment terms are acceptable?

T/T,L/C

Q:What's the minunm order quantity?

For the rotomolding machine and mould,the MOQ is 1 set. For plastic products,we can further negotiate.

Q:Do you test all your goods before delivery?

Sure.Our professionals will carefully check the products before they leave the factory to ensure that you receive no problems with the products.

Q:What about your after service?

1.During the warranty time,if the products exist any quality problems,please contact us at once,and we will offer you satisfactory solution as possible.

2.We contact to our customers regularly for getting valuable feedback.

Q:Can we visit your factory?

Welcome all of you to visit our foctory and we can pick you up.